Plant engineers are always challenged to maintain the greatest levels of operating efficiency for all of their equipment. The issue of water quality has remained essential throughout this process. The quality of the source water affects every process or equipment that requires water to operate, such as boilers, cooling towers, washing or rinsing processes, and so on. Water quality is not only a concern, but it also has an impact on equipment reliability and, ultimately, product quality.

Water treatment! An Investment!

Water treatment expenditures should be viewed as an investment in plant equipment protection. Water treatment equipment costs should be more than covered by the savings obtained from enhanced product quality, equipment dependability, and overall plant efficiency when appropriately specified.The trick is to make sure that all of the necessary equipment is specified correctly. Water quality requirements are sometimes set by equipment makers. However, these performance criteria are frequently unknown. Pre-treatment requirements for identical equipment may differ depending on location due to varying source water quality.

When it comes to water treatment for a facility, there are a few key questions to consider!

1. When should you test the water?

If you notice any indicators of a condition that could be related to water quality, have the water tested very away. The most common problem signals are detected in the operation of boilers and cooling towers.

2. What to do if you want to know what's in the water?

There are three places where you can get information about the water supply.

-If the water is supplied by a municipality, contact them for current analysis.

-If the water comes from a private well, have it checked by a local water treatment specialist.

-Contacting a local testing laboratory to analyse the source water is a third alternative.

3. What should the water be checked for?

The following list of criteria should be examined if the water is utilised as work water for rinsing/washing, chilling, or heat transfer.

- TDS (total dissolved solids)

- TSS (total suspended solids)

- Hardness

- Chlorine

- Alkalinity

- Silica

- Iron

- Chlorides

- pH

- Bacteria

4. What is the most effective water treatment technology?

There are no such things as "best" technology. Each one is used to deal with a different sort of water contamination. The following are examples of common water treatment technologies:

-Filtration: for the reduction of suspended solids, removal of some bacteria and iron, and absorption of chlorine.

-Softening: for the removal of hardness and dissolved iron.

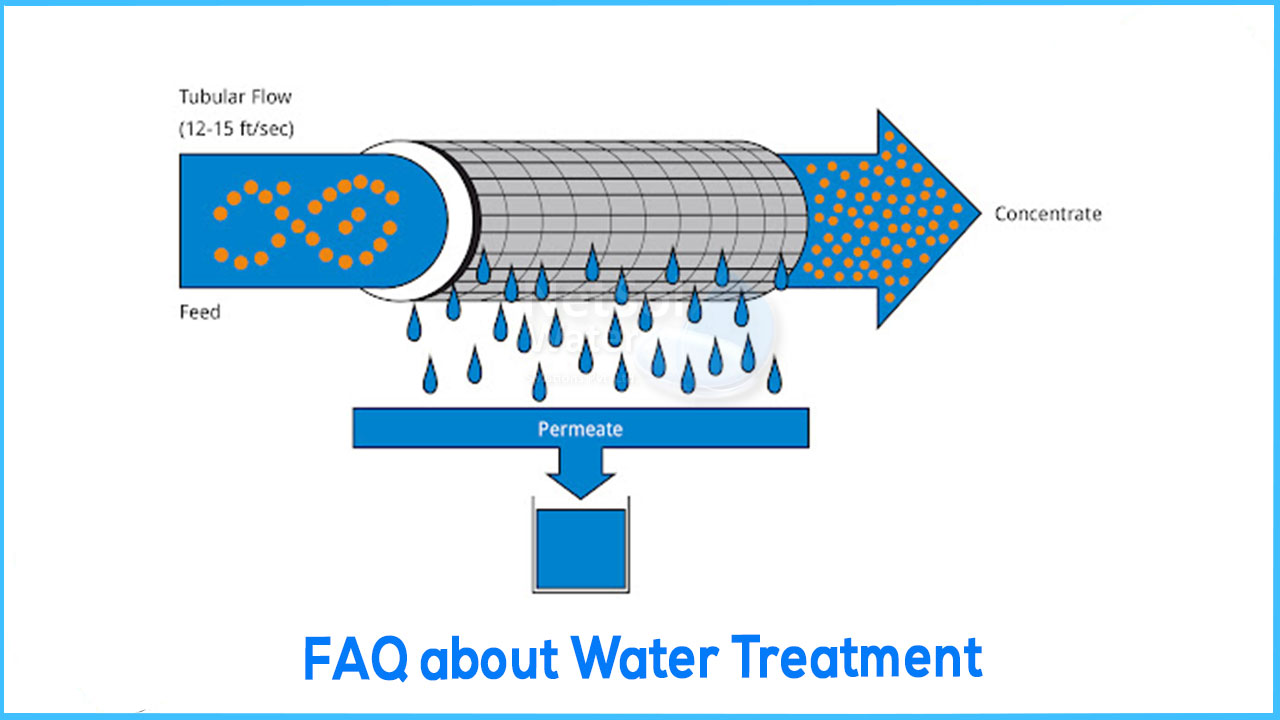

-Reverse Osmosis: for the reduction of TDS, chlorides, silica, and sub-micron suspended solids

5. When do you think the water should be treated?

The treatment of water is determined on the application. There is a minimum requirement for each use of water. Treatment is unavoidable if the source water does not fulfil process criteria. Even if the water quality satisfies the required standards, extra treatment may provide cost savings.

6. What is the cost of treatment?

The total cost is determined by the quality of the source water and the desired level of water improvement. Different systems have different capital costs.

7. When it comes to water treatment equipment, how long does it last?

Although most water treatment systems depreciate over a seven-year period, they have a replacement life of 15 to 25 years. Most key components need to be replaced after 7 years, and the decision of whether to repair or buy new equipment should be investigated. New equipment is indicated if technological advancements may give a solution that is more efficient and covers the costs of removing old equipment, purchasing new equipment, and installing it.

8. What are the most important factors to consider when purchasing water treatment equipment’s?

When looking into purchasing or rebuilding an existing water purification system, three aspects should be taken into account: pricing, product, and service. Each of these elements interact to determine the overall value on offer.

9. What are the most recent advancements in water treatment?

Although the technology has remained the same, their application has evolved from rigorous source water treatment to integrated recycling systems that can accept processed water and recovery and reuse it during the process. Condensate return loops for boilers, zero blow down cooling tower systems, and process waters recycled for washing and rinsing are just a few examples. Water treatment can regenerate a resource that was previously thrown away in each of these applications. Recycling reduces many facilities' reliance on their water supply while also lowering costs and adding to the bottom line.