What are the Factors that influence proper operation of CETP?

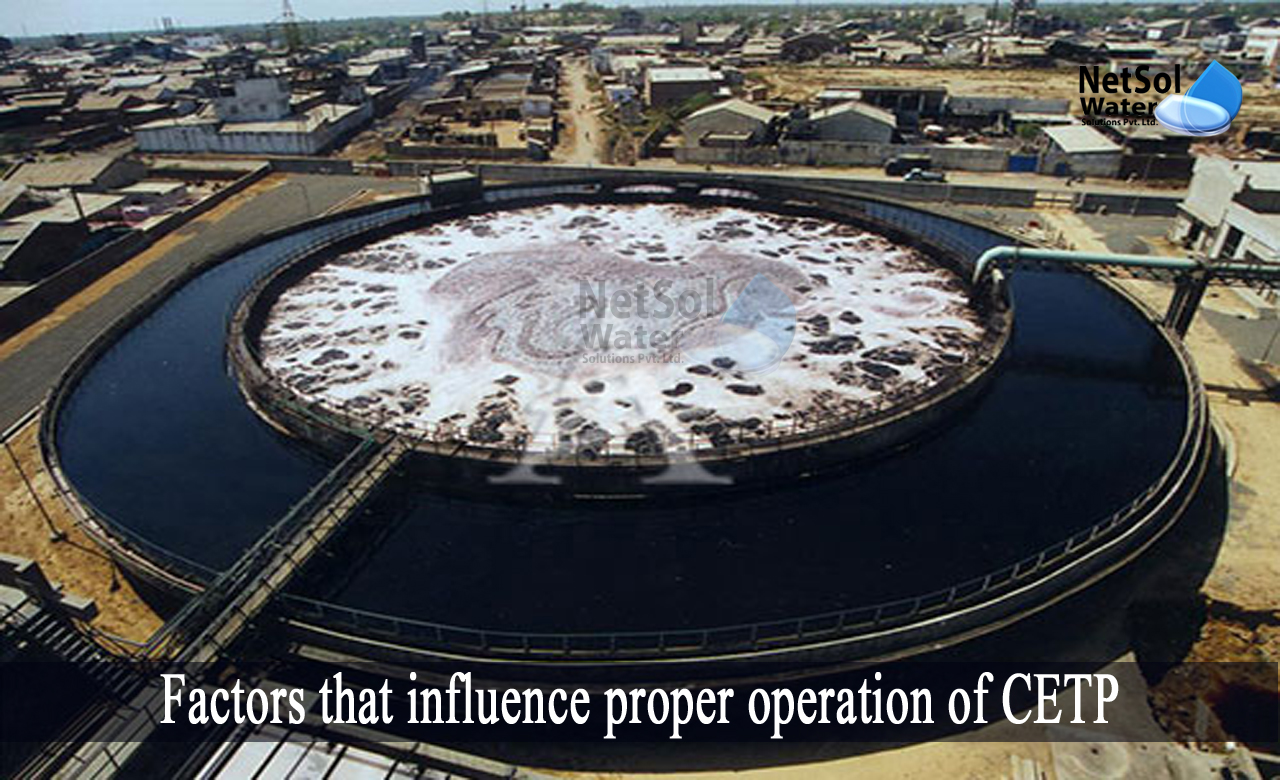

The concept of a common effluent treatment plant (CETP) was developed to allow for the collective treatment of effluents, from multiple industries at a centralized facility, allowing for the benefit of the scale of operation.

Over the years, it has been shown that co-treatment of sewage and natural stormwater, with industrial wastewaters, typically improves treatability, notably in the case of CETPs servicing chemical industries. But, there are several factors that influence the proper operation of CETPs. Let us discuss them in the blog.

Factors that influence proper operation of CETPs

- Types of effluent-generating member industries - homogenous, heterogeneous,

- Size of operation,

- Fluctuations in effluent quality - physical, chemical, and biological features;

- Changes in flow and future forecasts,

- Pre-treatment requirements

Itincludes compatibility with the conveyance system from the industry to the CETP, inlet quality standards established for different streams at the CETP, and equalization/homogenization requirements established for different treatment technologies at the CETP, immediately upon receipt of effluent from member industries.

- Separation of effluent streams at individual member industries

Because each treatment technique has parameter-specific removal efficiencies, dealing with heterogeneous wastewaters sometimes necessitates a mix of technologies.

Incompatibility of technologies with specific pollutants necessitates the separation of respective wastewaters, into a few groups at individual industries, such as high COD, bio-degradable, recalcitrant, metal bearing, and so on, corresponding to the existing/proposed combination of treatment schemes at CETP, for improved overall treatment efficiency.

- Respective Standards and mode of disposal

After treatment, wastewater can be released into the sea, freshwater bodies, on land, or sewers, as approved by the relevant SPCB. Each route of disposal has comparable requirements for treated wastewaters, for example, deep sea discharge is better off than others, due to dilution/insignificant consequences.

As a result, based on the receiving body's proximity and assimilation capability, the most cost-effective option may be picked.

- Collection/conveyance system, and monitoring mechanism

There are several forms of collection, including as open channels, pipes (underground/overground), and tankers, among others. Each mode has advantages and disadvantages in a particular environment. A necessary prerequisite is that member industries release only acceptable quality wastewater.

Furthermore, monitoring requirements vary depending on the method of conveyance; for example, in the case of a pipe network, continuous monitoring devices, as well as the frequency of monitoring matching to effluent quality fluctuations, are required. A key barrier is frequently a lack of a good collecting system with monitoring.

- Treatability, technology selection, bio-degradability, and interferences

Before finalizing any treatment scheme, treatability studies are required. However, the challenge remains, as the inlet quality of effluent changes over time, particularly when serving heterogeneous synthetic organic chemical industries. As a result, modular development in terms of size and technology selection is critical, for allowing CETP operators considerable flexibility to adapt to variations in flow and quality.

Considering treatability and economics, for example, a mix of technologies is frequently necessary. Biological therapy is less expensive than others, but it cannot handle poisonous or non-biodegradable materials. Thermal treatment, on the other hand, is costly but may be required to cope with both high organic and inorganics-containing wastewaters.

- Charging system

Costs can be categorized as capital, operational, or administrative. The Central Government program provides partial budgetary support in exchange for state governments, committing their respective share to the construction of CETPs. Often, these criteria vary.

Summary

Initial membership fees are collected for the creation of the corpus, and regular fees are levied based on various models, which frequently consider flow and critical pollutant concentrations, for proportionately charging, including collection, treatment, disposal, administrative, and depreciation costs, among other things.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.