Explain the Clean-in-place (CIP) procedure in RO Plants

Reverse osmosis and other membrane systems are regularly cleaned and sanitised by CIP systems, to get rid of fouling and improve performance. Larger systems are installed on steel frames, while smaller systems are mounted on a transportable cart. The whole set of tools required for membrane cleaning activities is included in these packaged systems.

In this article, we will study about the clean-in-place or CIP procedure in RO plants, and why it is required.

Why is CIP procedure required in RO Plant membranes?

A top-notch filtering system is necessary to successfully and even smoothly, remove pollutants or other components from water. An advanced membrane system in a RO system is crucial to the unit's ability, to carry out the necessary high-end filtering at a level that produces an acceptable result.

The RO system has a very difficult time operating properly or performing any useful tasks at all, when its membranes are dirty or contaminated. Thus, reverse osmosis CIP cleaning solutions may be employed to address the issues, brought on by a filthy membrane and provide the desired effects. Thus,

· It helps in the removal of ionic and organic fouling that affects membrane performance.

· It restores membrane performance to nearly new levels.

· It increases the longevity of your membranes.

· It enhances the quality of membrane water.

What is clean in place or CIP in RO Plants?

The CIP procedure, which stands for clean-in-place, helps clean the membranes without using excessive force, so system damage is unlikely. To put it mildly, cleaning techniques that harm the membrane won't be very effective. If this is the case, the membranes are unable to correctly carry out their necessary functions.

Therefore, a RO system can be chemically cleaned and thoroughly sanitised using CIP cleaning equipment. Thought must be given to the selection of the compounds. In fact, corrosion brought on by harsh chemicals may require repairs or, worse, system replacement.

Procedure of CIP in RO Plants

To ensure the normal operation of the membrane system and increase the service life of the membrane module, CIP removes macromolecular colloids, microorganisms, organic matter, inorganic substances, and other fouling that has fouled on the surface of the RO membrane module, during long-term operation.

In general, when the RO system's rate of desalination or water production is dropped to 10-15%, it is necessary to execute CIP treatment on the RO membrane module in order to safeguard RO membrane modules, and lengthen their service lives. For your convenience, the CIP steps are listed below:

· Cleaning/rinsing with water

To get rid of dirt and other leftover materials on the surface, rinse RO membrane modules and system pipes with water, heated to between 60 and 80 °C. Any water that fits the criteria for RO inlet water may be used for washing, including RO-produced water. Cleaning typically takes 10 to 15 minutes.

· Cleaning/rinsing with alkaline cleaning solutions

Clean the RO membrane modules and system pipes with an alkaline cleaning solution with a 1-2% concentration, while maintaining a temperature range of 60 to 80 degrees Celsius. It will remove contaminants such as the fats, proteins, etc.

Typically, cleaning takes 10 to 15 minutes. While clean-up is going on, keep a constant check on the pollution level in the backwater. If the CIP's backwater becomes darker and more turbid due to rising pollution level, the cleaning fluid needs to be evacuated and adjusted.

· Cleaning/rinsing with water

Following the completion of the alkaline cleaning procedure, the RO membrane module and the system pipeline are rinsed with water at a temperature of 60 to 80 °C, to remove alkaline solutions which are still present.

For checking that the difference between pH value of the cleaning inlet water, as well as the discharge cleaning water, is lesser than 0.5 after cleaning for 5 to 10 min, use pH test paper.

· Cleaning/rinsing with acid cleaning solutions

To eliminate inorganic salts, minerals, metal ions, and other contaminants, prepare an acidic cleaning solution with a 0.5–1% concentration, keep the temperature between 60–80°C, and clean the RO membrane modules and system pipes. Typically, cleaning takes 15-20 minutes.

· Final cleaning/rinsing with water

The RO membrane modules and system pipes are rinsed with water at a temperature of 60 to 80 °C, after the acid cleaning operation is complete to eliminate any acidic cleaning fluid that may have remained in them.

After cleaning for 5 to 10 minutes, test the water using pH test paper to make sure the difference in pH, between the cleaning inflow water and the cleaning water that is discharged is less than 0.5.

Note:

1: The RO Plant produces water with the best quality when it is combined with an alkaline and acidic cleaning solution.

2: For making alkaline and acidic cleaning solutions, the personal protection equipment’s should be utilized.

3: It is also suggested to put on a safety gear which may include gloves, clothes and goggles.

4: CIP cleaning tank should first be filled with water, before adding acid and alkali stock solutions.

Types of clean in place or CIP systems

There are several types of cleaning-in-place systems:

· Single-pass method system

1: The plant is given a fresh cleaning solution to use while being cleaned, before being disposed of down the drain.

2: A pre-rinse is typically the first step in a single pass system to get rid of as much soiling as feasible.

3: This would be followed by a final rinse and the detergent cleaning.

· Recirculation method

1: The cleaning solution is prepared in an external tank before being applied to the plant.

2: Up until the cleaning cycle is over, it is re-circulated and topped off as necessary.

3: After the detergent clean is finished, a final rinse is usually performed.

Recirculation systems demand more capital investment, use less water and cleaning agents, but they may not be viable in some situations due to contamination from one operation to another.

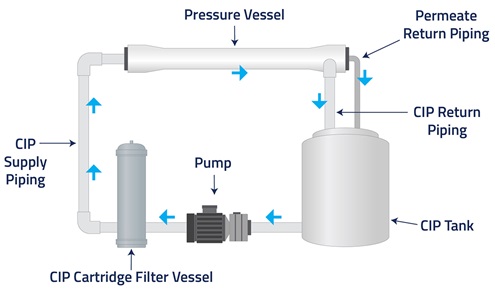

Fig: Clean in place system

Applications of clean in place systems

Dairies and breweries have long utilised CIP, but other facilities have adopted it due to equipment and installation costs, as well as the difficulties of cleaning some processing equipment. CIP could thus be applied to:

· Liquid filling, particularly in the dairy sector

· Dairy items

· Food with a limited shelf life

· Conveyors for unpackaged goods

· For meat packaging systems

· Post-pasteurization ice cream making

· Production of sandwiches

· RO Plants and other membrane systems

How do you know you should use Clean in place procedure? When to use CIP procedure?

Follow the Clean-in-Place (CIP) instructions provided by the manufacturer of the membrane. Determine the ideal circumstances and timing to schedule a CIP using normalisation formulas.

The membranes may suffer irreparable harm if you wait too long. Thus, CIP procedure must be followed when:

- 10% less normalised flow is seen.

- 15% rise in dP after normalisation is seen.

- The passage of normalised salt rises by 5%.

It is advisable to get in touch with a clean-in-place unit provider if you have serious doubts, about whether you are approaching CIP cleaning correctly. It is also strongly advised to have a CIP specially ordered for a RO system, which either doesn't have one or is using an older, less effective one system.

How can we assist you in providing clean drinking water?

Netsol Water professionals may look over your membranes, identify any issues they find, and then offer advice on what CIP procedure will keep such issues from happening again in the future.

From that point on, a new cleaning schedule may be put in place, and your RO system should continue to function flawlessly. We are the leading manufacturer, supplier, and exporter of a quality selection of Commercial RO Plants and Industrial RO plants in India.

Among the industries we serve with water and wastewater treatment systems, are the pulp & paper, automobile, food, beverage, textile, pharmaceutical, refineries, hotels, schools, office buildings, and hospitals, etc. Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.