How to know everything about Zero liquid discharge plants?

If this is the case, you have come to the correct spot. There are many different sorts of industries that produce wastewater across the world. All of them, however, are unable to carry out the process of zero liquid discharge water treatment since it is both costly and difficult.

If the business or industrial unit is located in an area where water scarcity is already a concern, then the ZLD water treatment is the ideal alternative.Before deciding on this form of water treatment, one should make all of the relevant considerations regarding it and whether or not it would be useful.

What exactly is ZLD?

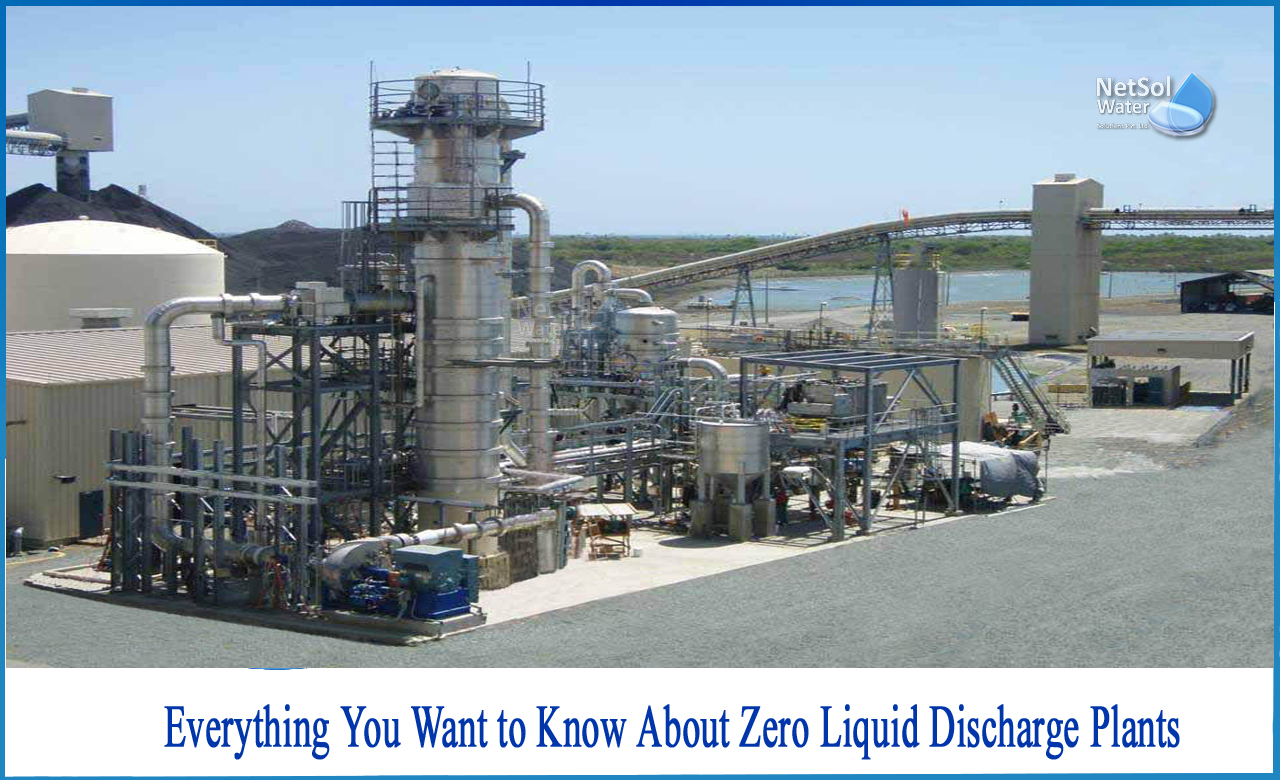

Zero Liquid Discharge (ZLD) is a treatment method that eliminates all liquid waste from a system. The goal of ZLD is todecrease wastewater and create clean water suitable for reuse (e.g., irrigation), hence saving money and benefiting the environment. ZLD systems purify and recycle nearly all of the wastewater generated using modern wastewater/desalination treatment technologies.

ZLD technology also assist facilities in meeting discharge and water reuse criteria, allowing enterprises to:

1: Comply with severe Government discharge rules;

2: Achieve better water recovery (percentage);

3: Treat and recover valuable materials from wastewater streams, such as potassium sulphate, caustic soda, sodium sulphate, lithium, and gypsum.

4: Thermal methods such as evaporators (multi stage flash (MSF), multi effect distillation (MED), and mechanical vapor compression (MCV)) and crystallizers are used to attain ZLD and recover their condensate. As a result, ZLD plants generate solid waste.

The primary functions of an advanced zero liquid discharge water treatment system are as follows:

- Deal with changes in waste contamination and flow;

- Allow for changes to the chemical volumes;

- 95 percent of water waste should be appropriately treated and recyclable for reuse;

- Important minerals such as salts and brines can be recovered by processing water waste;

- The waste would be produced in the form of a dry, solid cake.

One of the most significant advantages of zero liquid discharge water treatment is that it adheres to the rules established by the Environmental Protection Agency. Everyone should keep in mind, however, that their factory's need for zero liquid discharge is dependent on whether the liquid waste will be released in publicly owned treatment facilities or in regions covered by the National Pollutant Discharge Elimination System.

Regardless of the varied sources of a wastewater stream, a ZLD system normally consists of two phases.

1: Pre-concentration

Pre-concentration of brine is often accomplished using membrane brine concentrators or electrodialysis (ED). These methods can recover up to 60–80 percent of the water by concentrating the stream to a high salinity.

2: Evaporation/Crystallization

The next step with thermal processes or evaporation, evaporates all the leftover water, collect it, and drives it for reuse. The waste that is left behind then goes to a crystallizer which boils all the water until all the impurities crystallize and are filtered out as a solid.

How do these zero-liquid-disposal therapies work?

The liquid waste is handled using numerous filtration procedures to ensure that no or very little liquid waste is created at the end. However, this procedure is quite expensive, including the cost of the membrane bioreactor.

It is important to note that each facility or plant has unique needs, and the ZLD procedure varies accordingly. The budget is also subject to change based on the needs of the project.

Select a firm with appropriate experience in this industry!

It is critical to select a business with suitable experience in this sort of job and sector.To pitch better offers, the buyer should always conduct thorough research and haggle the price of the service.

What can we offer?

Netsol Water is a significant water and wastewater treatment firm in India, offering WTP, WWTP, STP, ETP, RO Plant, ZLD Plant, and MBR manufacture, among other services. The company creates equipment’s and is committed to providing practical solutions that help businesses flourish. We are committed to providing our valued customers with hands-on service, expert counselling, and training.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.