What is an Industrial Water Softener?

The process of eliminating the dissolved calcium and magnesium ions that produce hardness in water is known as water softening.

Unlike hard water, softened water does not form insoluble scale or precipitates in pipes and tanks, nor does it interfere with cleaning agents such as soap. Many businesses require water softening, and modest water softening machines are utilized in residences as well as a number of industries in almost every nation.

Why do Industries need Water Softeners?

Hard water can be an issue because the calcium and magnesium ions react with the soap's higher fatty acids to produce an insoluble gelatinous curd, resulting in soap waste (this objectionable reaction does not take place with modern detergents). Hard water contains calcium and magnesium, which cause a hard, adherent scale on boiler plates. As a result of the scale's poor heat conductivity, fuel consumption rises, and the boiler quickly degrades owing to exterior plate overheating.If there is sodium carbonate, it hydrolyses to create free alkali, which causes caustic embrittlement and boiler plate failure.

Processes involved in Industrial Water Softening

Two strategies for softening water include ion exchange and adding chemicals that produce insoluble precipitates.

1: Some of the chemicals used for softening on a small scale include ammonia, borax, calcium hydroxide (slaked lime), and trisodium phosphate, which are generally combined with sodium carbonate (soda ash). The lime-soda technique of water softening must be followed by sedimentation and filtering to remove the precipitates. Water may be chemically softened on a large scale by adding just enough lime to precipitate the calcium as carbonate and the magnesium as hydroxide, then adding sodium carbonate to remove any remaining calcium salts.

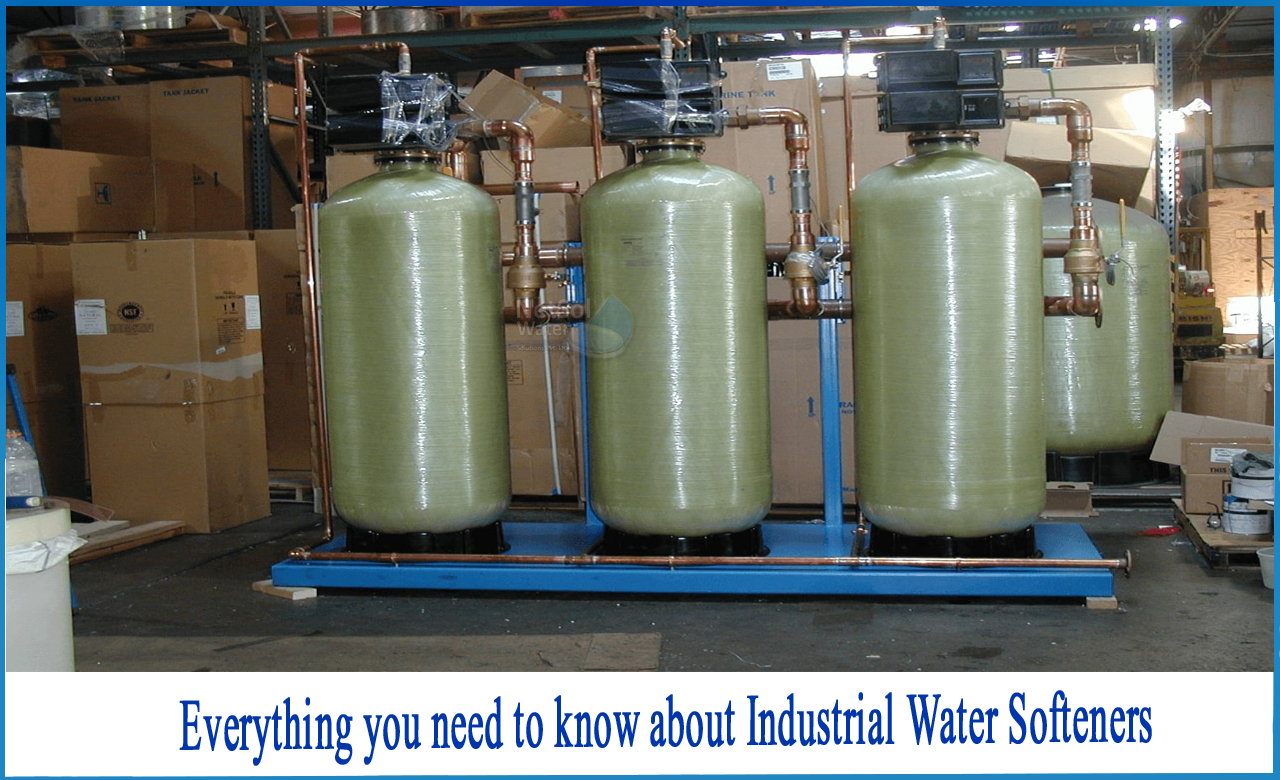

2: Ion exchange water softening is a common industrial practice. Sodium ions are exchanged for calcium and magnesium ions as water passes through columns of natural or synthetic resin.Calcium and magnesium begin to emerge in the water exiting the column after it has been in use for a while.

After flushing with water, the column must be regenerated by gently flowing a concentrated solution of common salt down it; the surplus sodium ions displace the ions that cause hardness, and the exchanger bed is ready to use again.Natural aluminosilicates were first employed as heat exchangers, but synthetic resins were eventually substituted.

Home water softeners function in a similar way, using zeolite or another ion-exchange resin in a tank that is directly linked to the water supply.

Conclusion

The mineral balance of incoming water to industrial systems is essential for the proper operation and maintenance of expensive gear. Delivering a consistent end result is also essential. To keep the industrial process running, industrial water softeners remove excess minerals like calcium and magnesium to a predetermined and regulated level.

The process of industrial water purification and softening transforms unfit water for industrial use into water that is free of sediments and pollutants, as well as having the proper pH balance.

Are you looking for the most cost-effective Water Softeners in India?

Netsol Water experienced advice can guarantee that your industrial water meets or surpasses industry requirements for filtration, passing inspections with flying colours. Based on your plant's demands, process parameters, and the amount and flow rate necessary for your systems, we will carefully construct the optimum industrial water treatment solutions including Industrial Reverse Osmosis Plants and Water Softeners.

Our industrial water softeners come with corrosion-resistant carbon steel or fibreglass tanks for maximum customization. Top-of-the-line flow technology aids in upfront cost reductions as well as long-term maintenance savings. This enables for the creation of a unique industrial water softening system that is correctly suited for your process requirements, reducing both initial and ongoing costs. Our industrial water softening range is the most comprehensive in the industry, meeting the most stringent hardness and scale reduction standards.