ETP for Automobile or Auto parts manufacturing Industries

The automobile and auto parts manufacturing industries are known for their significant contributions to the global economy. However, these industries generate large amounts of wastewater during the production process, which can have a detrimental impact on the environment if not treated properly. This is where Effluent Treatment Plants (ETPs) come into play, as they are designed to treat and manage the wastewater generated during the production process.

So here we will discuss the design process of an ETP for Automobile or Auto Parts Manufacturing Industries, including the process flow diagram and working process in detail.

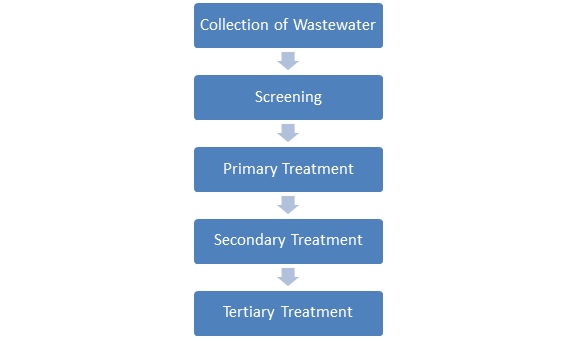

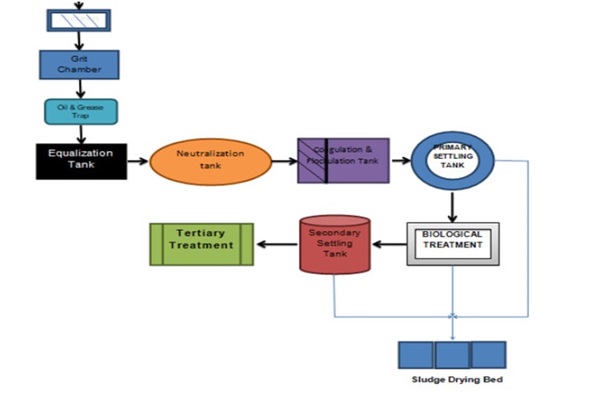

Process Flow Diagram

The following process flow diagram outlines the various stages involved in designing ETP for Automobile Manufacturing Industries:

Working Process and Function:

1. Collection of Wastewater:

The first step in the working process of an ETP is the collection of wastewater from various sources, such as washing, cleaning, cooling, and manufacturing processes. It is important to ensure that all wastewater is collected and transferred to a storage tank for further treatment.

2. Screening:

The next stage involves the screening of the wastewater to remove large debris and solids. This is achieved using a bar screen or a mechanical screen, which prevents the entry of unwanted materials into the treatment process.

3. Primary Treatment:

The wastewater is then subjected to primary treatment, where the separation of settleable organic and inorganic solids from the wastewater occurs. This is achieved through a sedimentation tank, where the wastewater is allowed to settle, and the solids are removed as sludge. The sludge is then sent to a sludge treatment plant for further treatment.

4. Secondary Treatment:

In the secondary treatment stage, biological treatment of wastewater takes place to remove dissolved organic matter. This is achieved through an activated sludge process, where the wastewater is mixed with a microbial culture that breaks down the organic matter. The wastewater is then passed through a clarifier to remove the biomass.

5. Tertiary Treatment:

In the final stage of the ETP process, advanced treatment is performed to remove any remaining contaminants. This may include chemical coagulation, flocculation, and filtration. The treated wastewater is then disinfected using chlorine or ultraviolet radiation to kill any remaining pathogens.

Note:

It is important to note that the design of an ETP for Automobile and Auto Parts Manufacturing Industries must be tailored to the specific requirements of the industry. Factors must be taken into consideration during the design process such as:

· The volume of wastewater.

· The composition of wastewater,

· The local regulations and environmental standards,.

Summary:

The design process of an ETP for Automobile or Auto Parts Manufacturing Industries involves a systematic approach to ensure the efficient treatment and management of wastewater. The process flow diagram highlights the various stages involved in the design process, including the collection of wastewater, screening, primary treatment, secondary treatment, and tertiary treatment. The working process and function of the ETP involves ensuring that all wastewater is collected and transferred to a storage tank, followed by screening, primary treatment, secondary treatment, and tertiary treatment to remove contaminants and disinfect the treated wastewater.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.