ETP design and data for different Industries ETP plants with drawing

Effluent treatment plants (ETPs) are crucial for treating industrial wastewater before it is discharged into the environment. ETP design depends on the type and quantity of pollutants present in the effluent, as well as the discharge regulations and standards set by the local authorities.

In this blog, we will discuss the design and data for a few ETPs with design and drawing in detail.

Design of ETPs:

The design of an ETP involves several processes, including screening, primary treatment, secondary treatment, and tertiary treatment. The primary treatment process involves physical and chemical treatment to remove suspended solids and organic matter from the effluent. The secondary treatment process involves biological treatment to remove dissolved organic matter from the effluent. The tertiary treatment process involves advanced treatment to remove any remaining pollutants from the effluent.

Data for ETPs:

The data required for designing an ETP includes the flow rate of the effluent, the characteristics of the effluent, and the discharge standards set by the local authorities. The flow rate of the effluent determines the size of the ETP required to treat the effluent effectively. The characteristics of the effluent, including the pH, temperature, and pollutants present, determine the treatment processes required to treat the effluent effectively. The discharge standards set by the local authorities determine the level of treatment required to meet the standards.

Design and Drawing of ETPs:

Here are a few examples of ETPs with their design and drawings:

-

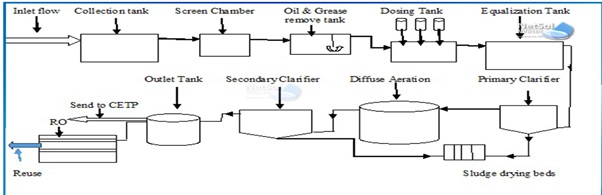

Textile ETP:

The textile industry produces wastewater with high levels of suspended solids, color, and chemicals. The ETP for a textile industry typically includes a screening process, a primary clarifier, an activated sludge process, and a tertiary treatment process. The design of the ETP for a textile industry depends on the flow rate of the effluent, the characteristics of the effluent, and the discharge standards set by the local authorities.

-

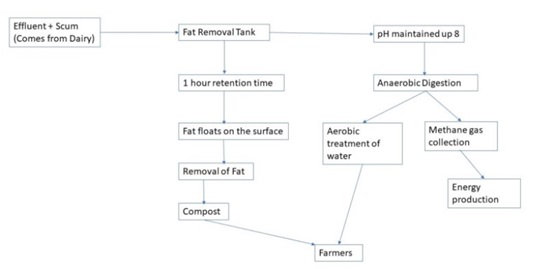

Dairy ETP:

The dairy industry produces wastewater with high levels of organic matter, fats, and nutrients. The ETP for a dairy industry typically includes a screening process, a primary clarifier, an anaerobic reactor, an aerobic reactor, and a tertiary treatment process. The design of the ETP for a dairy industry depends on the flow rate of the effluent, the characteristics of the effluent, and the discharge standards set by the local authorities.

-

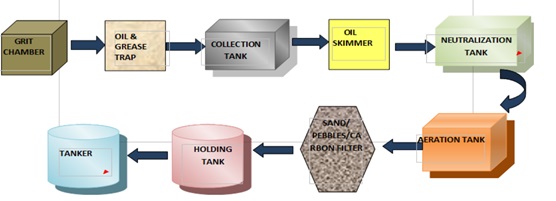

Chemical ETP:

The chemical industry produces wastewater with high levels of chemicals and metals. The ETP for a chemical industry typically includes a screening process, a primary clarifier, a chemical treatment process, an activated sludge process, and a tertiary treatment process. The design of the ETP for a chemical industry depends on the flow rate of the effluent, the characteristics of the effluent, and the discharge standards set by the local authorities.

Conclusion:

Effluent treatment plants are essential for treating industrial wastewater before it is discharged into the environment. The design of an ETP depends on the type and quantity of pollutants present in the effluent, as well as the discharge regulations and standards set by the local authorities. The data required for designing an ETP includes the flow rate of the effluent, the characteristics of the effluent, and the discharge standards set by the local authorities. The design and drawing of an ETP typically includes screening, primary treatment, secondary treatment, and tertiary treatment processes.

To get in touch with us and to relish the benefits of our services, call us at +91-9650608473 or send an email to enquiry@netsolwater.com