Why ETP require for mining sector?

For mining applications, wastewater treatment is crucial. Water is crucial to the mining industry because it is used in mineral processing to extract precious metals from ore. Using water in this manner, on the other hand, causes mineral impurities and other particulates to collect in your process water supply.

Without treatment, this results in tainted mining effluent that cannot be reused or returned to the environment owing to community health concerns and environmental requirements. As a result, mining operations require a regular and dependable source of clean water to keep operations going.

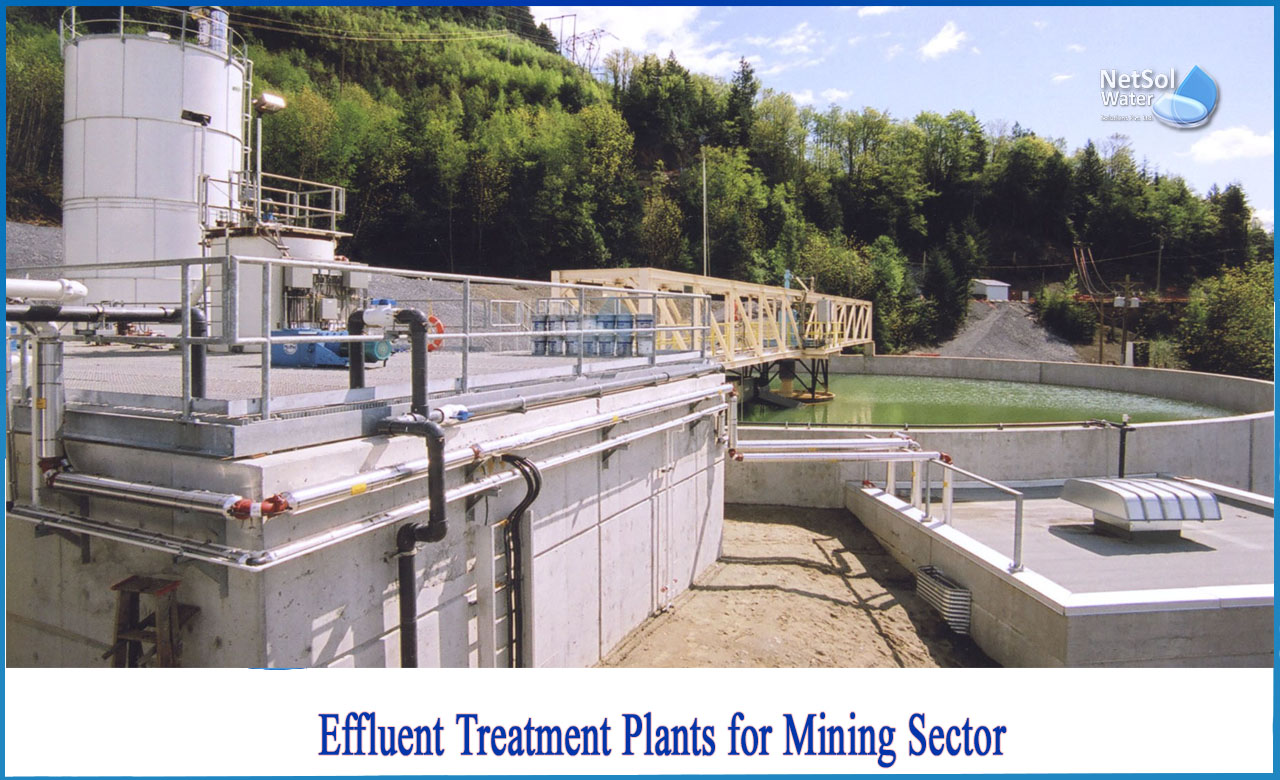

ETP Plant, which stands for Effluent Treatment Plant, is a procedure that is meant to treat industrial wastewater in order to make it reusable or safe for disposal into nature. It accepts untreated industrial wastewater as an influent and produces effluent as a consequence of treated industrial wastewater following treatment.

Issues in handling mining wastewater

While important for mineral processing, dealing with water that comes into contact with ore and other debris causes sections of the rock to leach into the process water. The acidity of the water will then increase as more metals and sulphates pollute it.

What is Mining-Influenced Water?

This technique produces mining-influenced water (MIW), which is defined as any water that has been chemically altered by mining or mineral processing.

The following are the most serious difficulties with mining-influenced water:

• Mine drainage containing acid

• Pollution from chemical processing

• Contamination and leaching of heavy metals

• Erosion and sedimentation

Any of these issues might cause your water to fail to meet regulatory requirements, requiring you to treat or dispose of the wastewater correctly.

Why should waste water from Mining sector treated?

There are a number of water-related issues that might jeopardize the efficacy of a mining site if adequate wastewater treatment is not implemented. This is due to the fact that mining wastewater and tailings are frequently quite acidic and heavy in suspended particles.

The following issues exist in uncontrolled mining applications:

• Acid evaporation from mine drainage and tailings heaps

• Pollution of groundwater

• Extremely saline waste

• Pollution of aquifers

These challenges are exacerbated by the fact that many potentially viable mine-mills are located in locations with already depleted water resources. Mining operations in these areas destroy the little fresh water that exists.

The optimum course of action, both environmentally and operationally, is to avoid contaminating outside water sources and to reuse mining effluent as much as feasible safely. Fortunately, improved wastewater treatment methods allow mine effluent to be reused for mining, irrigation, and even drinking water.

What is the process of Water Treatment for Mining Operations?

The major aims of water treatment, regardless of which water source is being treated, are to remove metals, sediments, and other pollutants from the water and to return the water to appropriate pH values. Mining wastewater treatment necessitates a combination of chemicals and mechanical filtration.

1: pH modifiers

One of the first steps in treating mining wastewater is to return the water to its appropriate pH level. This is vital not only for maintaining the quality of your water, but it will also aid in the precipitation of dissolved metals.Positively charged metal ions will react with negatively charged hydroxide ions when the pH of the water is raised. As a consequence, a dense and insoluble metal particle that is simpler to deal with is produced.

When used correctly, pH adjusters can assist to reduce the acidity of your mining wastewater, restoring it to more balanced pH levels. While a pH of 7 is technically neutral, it is advisable to raise the pH of your mining water to 8 or higher before proceeding with further treatment processes.

2: Flocculants and Coagulants

After you've adjusted the pH of your water, you may use coagulants and flocculants to mix the tiny metal particles and suspended solids in your water into bigger clumps. As a result, they are easier to filter out and remove mechanically.

3: Additional Substances

While the major chemicals used in mining wastewater treatment are pH adjusters, coagulants, and flocculants, certain applications require extra chemicals to safeguard your systems or to assist prepare your water for filtering. These are some examples:

• Ion exchangers and water softeners

• Corrosion inhibitors

• Biocides and algaecides

4: Filtration

Mechanical filtering methods can remove suspended particles and some forms of organic matter after you've enhanced the quality of your water with the correct chemicals. While there are a variety of devices available, the following are the most common types of mechanical filtering equipment:

• Centrifuges

• Presses for Filtering

• Presses for Belts

Netsol Water manufacture ETP’s for mining industries to properly treat water before disposing it off.