Effluent treatment plant for Food industry

Increased water consumption is a result of the evolution of numerous industrial sectors and expanded urbanization, as well as the formation of wastewater that is significantly diversified in nature, toxicity, and treatability. Food processing takes a huge amount of water, and the food industry/sector is the largest source of wastewater/effluent of all industrial activities. Because the strength of wastewater from food processing industries is generally high, it must be pre-treated before being discharged into the environment or reused. Simply put, all food processing firms must install an ETP, or Effluent Treatment Plant, for appropriate wastewater management.

What is effluent food industry?

As a bi-product of their manufacturing process, most companies produce wastewater, also known as effluent. The effluent/wastewater created has a wide range of flow and pollution strength, and it contains a number of contaminants/pollutants that can be eliminated using an effluent treatment facility (ETP).Processing food products necessitates a bigger volume of water in the food sector.

The strength and properties of wastewater released by the food and beverage industry varies. High amounts of suspended solids, total solids, BOD (Biological Oxygen Demand), COD (Chemical Oxygen Demand), dissolved oxygen, oil and grease, fats, sugar, color, preservatives, and usually nutrients such as nitrogen, ammonia, and phosphate are found in food industry effluent.

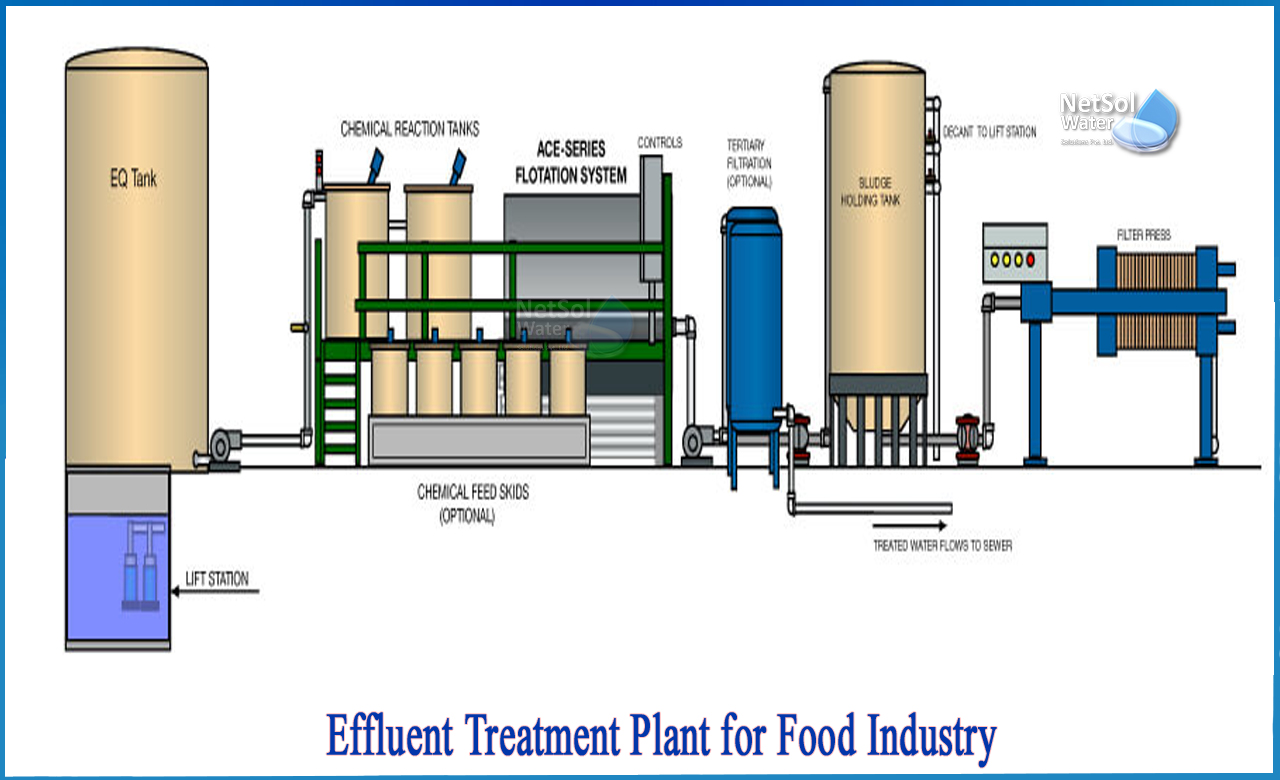

ETP - Proven and practical effluent/wastewater treatment solution in the food industry:

ETP for the food sector is designed and integrated with cutting-edge technology to prevent the spread of water-borne pathogens, which can cause infections and degrade receiving water bodies. ETP has proven to be an efficient option for wastewater treatment applications because it considerably decreases the negative effects of effluents on aquatic ecosystems and humans.

The easiest solution to avoid water pollution is to build an effluent treatment plant (ETP) for food and food processing enterprises. Its primary goal is to create a product that may be safely released into a watercourse or sewer while staying under the recommended discharge limits.

Various treatment methods and effluent treatment plant (ETP) levels:

The three wastewater treatment technologies utilized in ETP for the food industry to decrease the potential environmental impact are listed below.

1. Physical Therapy Techniques

2. Methods of Chemical Treatment and

3. Methods of Biological Treatment

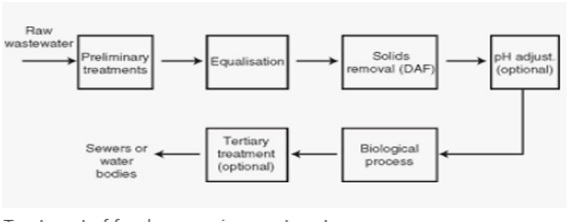

Preliminary treatment, primary treatment, secondary treatment, and tertiary treatment are the four treatment levels that ETPs typically go through. All of these treatmentprocesses/levels have the capacity to treat food sector wastewater and reduce its parameters to acceptable levels.

1. Pretreatment or preliminary treatment level:

This is the initial treatment level, and it eliminates coarse particles and other big items from effluent to protect subsequent treatment units. Coarse screening, grit removal, and, in some situations, breaking big materials into smaller objects are common first treatment activities. The wastewater that has been partially treated is now subjected to the primary treatment level.

2. Primary treatment:

Its goal is to remove big particles from wastewater using either physical settling or filtration. Separation of floating material and heavy materials from liquid waste is required. The primary clarifiers are capable of removing 50-60% of suspended particles. During primary sedimentation, oil and grease, organic nitrogen, organic phosphorus, and heavy metals linked with solids are also removed.

3. Secondary treatment level:

This treatment level's main goal is to remove suspended particles and residual organic materials utilizing aerobic and anaerobic processes. In secondary treatment, activated sludge is the most prevalent method. It entails the use of an aeration tank to provide oxygen to microorganisms, resulting in the removal of biodegradable dissolved and colloidal organic materials.

4. Treatment at the tertiary level:

This treatment level's goal is to improve effluent quality even further before it's discharged into the receiving environment. It eliminates pollutants that were not eliminated during the previous treatment stages. It uses a disinfection procedure (with chlorine, UV light, and ozone) that leaves no toxic residues in the wastewater that must be removed after treatment.Water that has been recovered after all of these treatment steps can be recycled and reused in the food sector for a variety of uses and applications.

To dispose of waste water generated from food sector safely, it requires a set of treatments to avoid contamination of land and water. It becomes essential to install Effluent Treatment Plants to obtain such water.

Netsol Water can help with regards to design, manufacture and installation of all such treatment facilities in Delhi NCR or outside.