Effluent Treatment Plant Design Criteria and Parameters

Effluent treatment plays an important role in protecting water bodies and public health. India is famous for its rivers, industries and fast growing cities. These same strengths also create pressure on water resources. Industrial growth releases wastewater that needs proper treatment before discharge or reuse. This is where effluent treatment planning becomes important. A well planned Effluent Treatment Plant helps industries meet pollution rules while saving water and cost in the long run.Designing an effluent system involves clear thinking about wastewater quality, flow changes, land space and future expansion. When engineers follow correct design criteria they reduce failure risks and ensure smooth plant operation. Many industries face problems because they ignore basic parameters at the planning stage. Poor design leads to higher running cost and non compliance issues later. Netsol Water as a leading Effluent Treatment Plant Manufacturer focuses strongly on design clarity and practical engineering. The right design approach helps industries meet present needs and prepare for future demands. Understanding the design criteria and parameters helps decision makers choose the right plant.

Understanding Effluent Characteristics and Load

Effluent characteristics form the foundation of every treatment plant design. Without knowing what comes into the system no engineer can design a stable solution. This step decides the success or failure of the entire plant. Let us have a look on some key aspects that define wastewater quality and load.

1: Nature of Wastewater

Every industry generates different wastewater. Textile units release color and chemicals. Food plants release organic waste. Pharma units release complex compounds. Designers must study pH, temperature, oil content, suspended solids and chemical load. These values guide the selection of treatment processes. When engineers understand the nature of effluent they can avoid overdesign and under design issues.

Wastewater quality also changes during the day. Batch processes release shock loads while continuous processes stay more stable. Designers must consider peak loads not average values. This approach protects the plant during sudden changes.

2: Flow Rate and Load Variation

Flow rate decides tank size and retention time. Many plants fail because they only consider current flow. Production growth increases wastewater volume over time. Designers must include safety margins and future expansion plans. Seasonal variation also affects flow especially in agro based industries.

Load variation affects biological treatment performance. High organic load needs longer treatment time. Designers calculate organic loading rate carefully to maintain system balance. By linking flow and load data engineers create a realistic design that works on ground conditions.

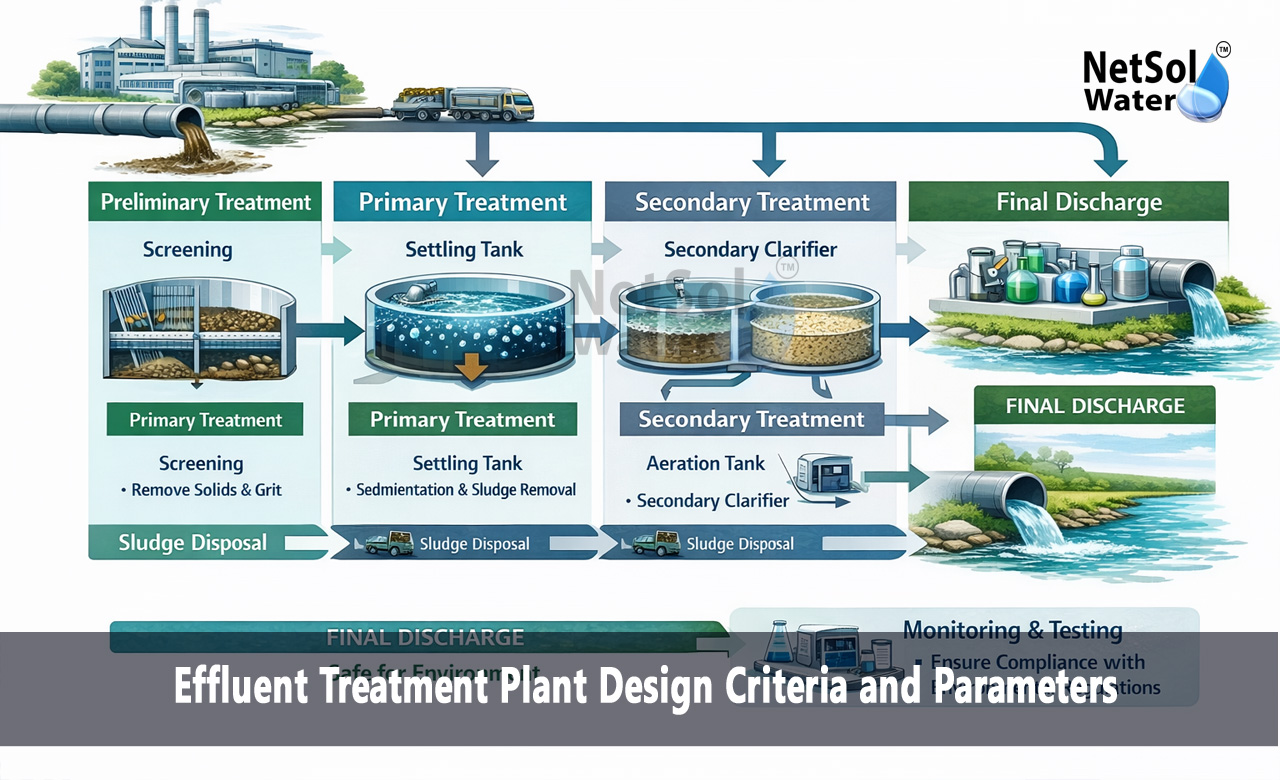

Process Selection and Treatment Stages

After understanding effluent quality the next step focuses on selecting the right treatment process. This stage connects theory with practical operation. Let us have a look on some key treatment stages and their role in plant performance.

1: Primary Treatment Criteria

Primary treatment removes large solids, oil and grit. Designers select screens equalization tanks and oil traps based on effluent type. Equalization tanks play a major role because they balance flow and load. A properly designed equalization tank improves downstream efficiency and reduces chemical use.

Designers also consider mixing method retention time and tank shape. Poor equalization leads to unstable biological performance. When primary treatment works well the entire plant benefits from steady operation.

2: Secondary and Tertiary Treatment Parameters

Secondary treatment focuses on organic removal. Designers choose between aerobic anaerobic or combined processes. Space availability energy cost and sludge handling influence this choice. Aerobic systems need more power while anaerobic systems need careful load control.

Tertiary treatment improves final water quality. Designers select filtration disinfection and polishing units based on reuse or discharge norms. Industries aiming for water reuse need advanced polishing. Each treatment stage must connect smoothly with the next stage to avoid hydraulic or process imbalance.

Hydraulic Design and Sludge Management

Hydraulic design controls how wastewater flows through the plant. Sludge management controls what remains after treatment. Both aspects deserve equal attention during design. Let us have a look on some important parameters that influence long term performance.

1: Hydraulic Flow Design

Hydraulic design ensures uniform flow without short circuiting. Designers calculate pipe size channel slope and tank inlet outlet positions. Incorrect hydraulics cause dead zones and overflow issues. Proper flow distribution improves treatment efficiency and reduces maintenance needs.

Gravity flow saves energy but needs careful elevation planning. Pump based systems need standby units and head loss calculation. Designers balance cost and reliability while selecting hydraulic arrangements.

2: Sludge Handling and Disposal

Sludge is a by product of treatment. Designers estimate sludge quantity based on load and process type. Thickening dewatering and drying systems need proper sizing. Poor sludge design creates operational headache and regulatory trouble.

Sludge disposal options depend on local rules. Some industries use composting while others send sludge to secured landfills. Designers plan sludge management from day one instead of treating it as an afterthought. This approach ensures compliance and stable plant operation.

Conclusion

Clear criteria and realistic parameters guide every engineering decision. An Effluent Treatment Plant designed with proper understanding performs better, costs less to operate and meets pollution norms consistently. Netsol Water brings practical design expertise backed by field experience as a trusted Effluent Treatment Plant Manufacturer. Industries planning a new Effluent Treatment Plant or upgrading an existing one can benefit from expert consultation.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com