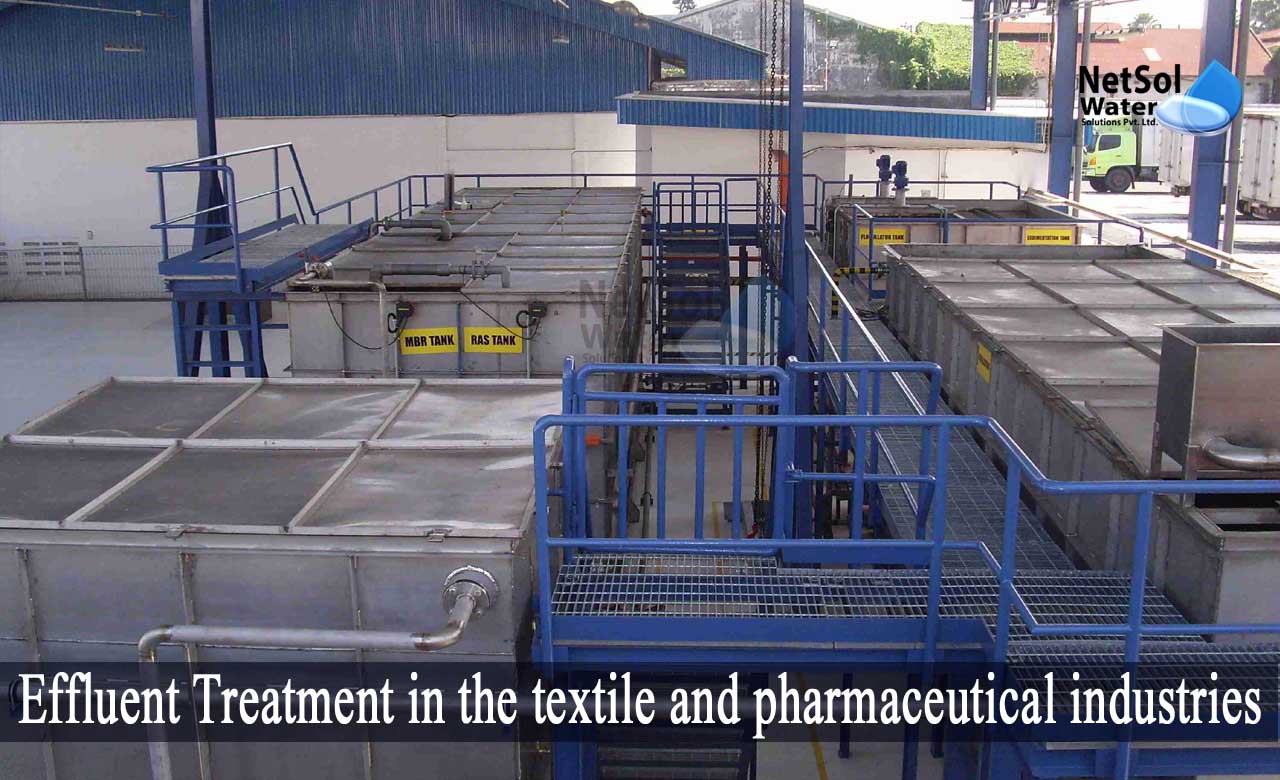

How to work ETP Plant in the textile and pharmaceutical industries?

When organic debris from industrial effluents enters water bodies, untreated, it serves as food for the bacteria that reside there. When such microscopic microbes degrade pollutants, they extract DO from the water.

The discharged inorganics are similarly difficult to breakdown. If they enter lakes and rivers through untreated wastewater, they remain there. When their concentrations rise over time, the water quality will become a worry for people and other creatures. As a result, wastewater treatment plants or effluent treatment plants are required for industries, so that water quality does not become a worry for the environment.

Textile effluent treatment procedures

Effluent treatment methods are classified into three types:

1. Primary Treatment

After eliminating abrasive particles, coarse solids, and large amounts of residual oil, first treatment in Effluent treatment plants is expected to remove, as many suspended particles as possible. It is based on sedimentation, which separates particles from water in a series of cells.

2. Secondary Treatment

The primary goal of secondary treatment in Effluent treatment plants is to remove more BOD, than could be removed by regular sedimentation. This method also eliminates a significant amount of colour, phenol, scattered and dispersed organic compounds, and oil from untreated wastewater.

3. Tertiary Treatment

Tertiary water treatment is the final stage of wastewater treatment in textile effluent treatment.During this stage, inorganic substances, viruses, bacteria, and parasites are all removed. After these hazardous chemicals have been eliminated, the treated water is safe to recycle, reuse, or release into the environment.

Techniques for treating wastewater in the pharmaceutical sector

1. Primary Treatment

Coagulation and Sedimentation

It is favoured to manifest in low-cost coagulating sedimentation processes. When wastewater suspended particles agglomerate in water, they lose their stability and cohesion, and big fragments sink. This method, which is extensively used in wastewater treatment, not only successfully decreases the concentration of pollutants, but also increases the biodegradability of wastewater.

Flotation

To bind to wastewater pollutants, flotation employs a carrier of highly distributed tiny bubbles.It may be used as a pretreatment for wastewater with a high suspended particle concentration, since it is less expensive, uses less energy, has a simple technique, and is very reliable.

2. Secondary Treatment

The following are the secondary treatment procedures:

|

Treatment |

Procedure |

|

Aerobic Treatment |

The traditional stimulated sludge approach |

|

Anaerobic Treatment |

Organic wastewater treatment at high concentrations |

|

Combined Treatment |

-SBR series micro electrolysis-anaerobic hydrolysis acidification method. -Contact oxidation as a pretreatment - BAF -Acidification caused by hydrolysis UASB-SB |

3. Tertiary Treatment

Technology for Supercritical Water Oxidation

It entails increasing the water pressure and temperature to the critical point. Organic materials can be oxidized in a homogenous oxygen-rich stage, after supercritical water generates oxygen. Furthermore, at a temperature of 400-600°C, it accelerates the reaction rate, allowing organic molecules in wastewater to achieve high disintegration efficiency, in a couple of seconds and complete the process.

N2, H2O, CO2, and H2 are formed from organic materials. Cl ions are transformed to a metal salt, whereas the nitro group in N2 is changed to sulphate. SCWO removes organic materials at a rate of 99.99 %.

Conclusion

The major purpose of the wastewater treatment process is to remove as many suspended particles as possible, before releasing the remaining water to the environment, and performing Wastewater Recovery. Depending on their needs and the kind of effluents, textile and pharmaceutical industries have their own wastewater treatment plants, called Effluent treatment plants or common effluent treatment plants.

How can we assist?

Netsol Water is one of the most reputable producers of ETP or Effluent treatment plants in India, utilizing cutting-edge technologies. As producers of textile and pharmaceutical effluent treatment systems, our goal is to eliminate contaminants from the wastewater, particularly sludge, till the last step of receiving quality treated water effectively and efficiently.