What are ion exchange resins?

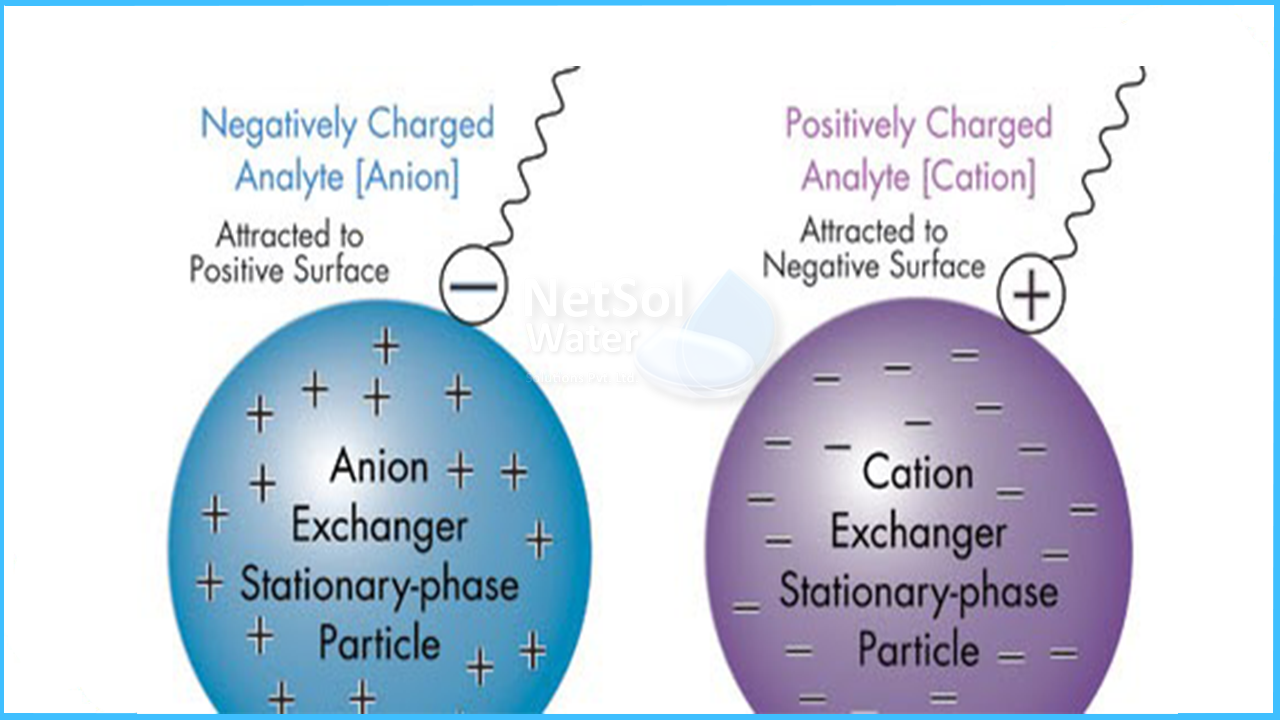

ION Exchange resins are substances that aid in IX reactions. They are made up of polymer matrices to which ionic "functional groups" of either positively or negatively charged ions (cations or anions) are permanently bound. These functional groups have a gross negative or positive charge, which allows them to easily inspire counter ions or ions with opposing charges.

Different types of ion exchange resins

Resins are named after the type of ions they exchange, Cationic resins interchange positively charged ions, while anionic resins exchange negatively charged ions.

- 1. Resins with high acid cation concentrations: Solid corrosive cation (SAC) trade pitches are among the most utilized gums. They are made out of a polymer grid to which anionic practical gatherings are bound. SAC saps are recovered with either a sodium salt arrangement (Na2+) for mellowing applications or with a corrosive (H+) for demineralization applications.

Application of High Acid Cation:SAC tars are widely used in calming applications because they are exceptionally effective at removing hardness of particles such as magnesium (Mg+) or calcium (Ca2+). They can also be used in split-stream de-alkalization, in which two SAC beds work in tandem, the first as a conditioner that delivers a soluble configuration and the second as a demineralizer (in the H+ structure), removing alkalinity from the mixed stream.

- 2. Acid cation resins with low acidity: Weak Acid Cation (WAC) trade pitches eliminate cations related with alkalinity (brief hardness). WAC gums normally utilize carboxylic corrosive utilitarian gatherings (RCOO–), and are recovered with sulphuric or hydrochloric corrosive.

Application of Weak Acid Cation:WAC pitches are used in demineralization and de-alkalization processes. Because of their high proclivity for divalent cation particles (Ca2+ and Mg2+), they are an excellent choice for applications requiring the evacuation of hardness particles associated with alkalinity. In a two-venture IX cycle, a WAC pitch can be used in front of a SAC tar for high transitory hardness applications. Furthermore, WAC pitches have a moderately high oxidation resistance and mechanical toughness, making them an excellent choice for streams containing oxidants such as hydrogen peroxide and chlorine, among others.

- 3. Anion resins with a strong base:Strong base anion (SBA) exchange resins are available in multiple varieties, including Type 1, Type 2, and acrylic or macro porous. Each type of SBA resin offers a unique set of benefits and constraints that must be matched to the application at hand.

Application of Strong Acid Anion: SBA resins are commonly used for demineralization, de-alkalization, and de-silication, and also the removal of total organic carbon (TOC) or other organics, depending on the resin type. Type 1 SBA resins are used for the selective removal of nitrates (NO3-), sulphates (SO3-), and perchlorates (ClO4-), general demineralization, and desilication where low silica levels are required. Type-2 SBA resins are used in applications where total anion removal is desired, lower caustic use is preferred, and low silica levels are not critical to company operations.

- 4. Base anion resins with low solubility: Low base anion (WBA) trade gums are the main significant kind of IX saps that don't have replaceable particles. These pitches adsorb free mineral acridity (Cl and SO4). WBA pitches have amine utilitarian gatherings, and are commonly recovered with sodium hydroxide (NaOH), smelling salts (NH3), or sodium carbonate (Na2CO3).

Application of Weak Acid Anion:WBA gums are used in the fractional demineralization process. WBA gum beds can be combined with SBA units in larger plants for complete demineralization applications, and WBA tars are also effective as all-natural carbon (TOC) boundaries in front of SBA beds. WBA is also used for corrosive adsorption applications such as the removal of chloride, sulphate, nitrate, and other anions associated with solid acids, but it is ineffective for the removal of feeble acids such as silica (SiO2) and carbon dioxide (CO2).

- 5. Resins of distinction: As their name implies, specialty resins are used for a variety of specific applications. Chelating resins are the most common type of specialty resin, and are used for selective removal of certain metals and other substances. Specialty resin functional groups vary widely depending upon the application.

Application of Resin of distinction: Chelating resins are used extensively for concentration and removal of metals in dilute solutions, such as Cobalt (Co2+) and Mercury (Hg2+). Another type of specialty resins are magnetic ion exchange (MIEX) resins, which are used for removal of natural organic matter from liquid streams.