What are the different types of anaerobic reactor?

To protect humans, animals, and plants, wastewater containing a large number of harmful compounds is thoroughly cleaned before being released into the environment. The anaerobic process, in which microorganisms digest organic matter, is one of the most successful and efficient biological processes for wastewater treatment. The procedure is carried out without the use of oxygen.

As the world becomes more industrialised and urbanised, a considerable volume of effluents with high organic content is produced. Anaerobic treatment is thought to be the best option for dealing with organic waste. The method is popular among Effluent Treatment Plants (ETPs) since it is simple and economical. This procedure treats all types of industrial waste, biowaste, animal manure, sewage, waste from agriculture, dairy, pulp, food, textiles, and municipal solid trash.

One of the most appealing aspects of anaerobic wastewater treatment is that it uses less energy and produces biogas as a by-product.

Most, if not all, anaerobic treatment processes include some sort of bioreactor, which aids anaerobic digestion by maintaining an oxygen-free environment. In most cases, the bioreactor contains sludge, which contains an anaerobic bacteria colony that works on wastewater as it enters the bioreactor.

Hydrolysis of complex organic and biodegradable materials to basic monomers, organic acids, and hydrogen is the first step. The second phase is acetogenesis, which involves converting volatile organic molecules into acetate and hydrogen. Finally, methanogenesis occurs when methanogens react with each other to produce methane and carbon dioxide. To carry out the anaerobic decomposition of organic matter, certain environmental conditions are required.

What are the different types of bioreactors?

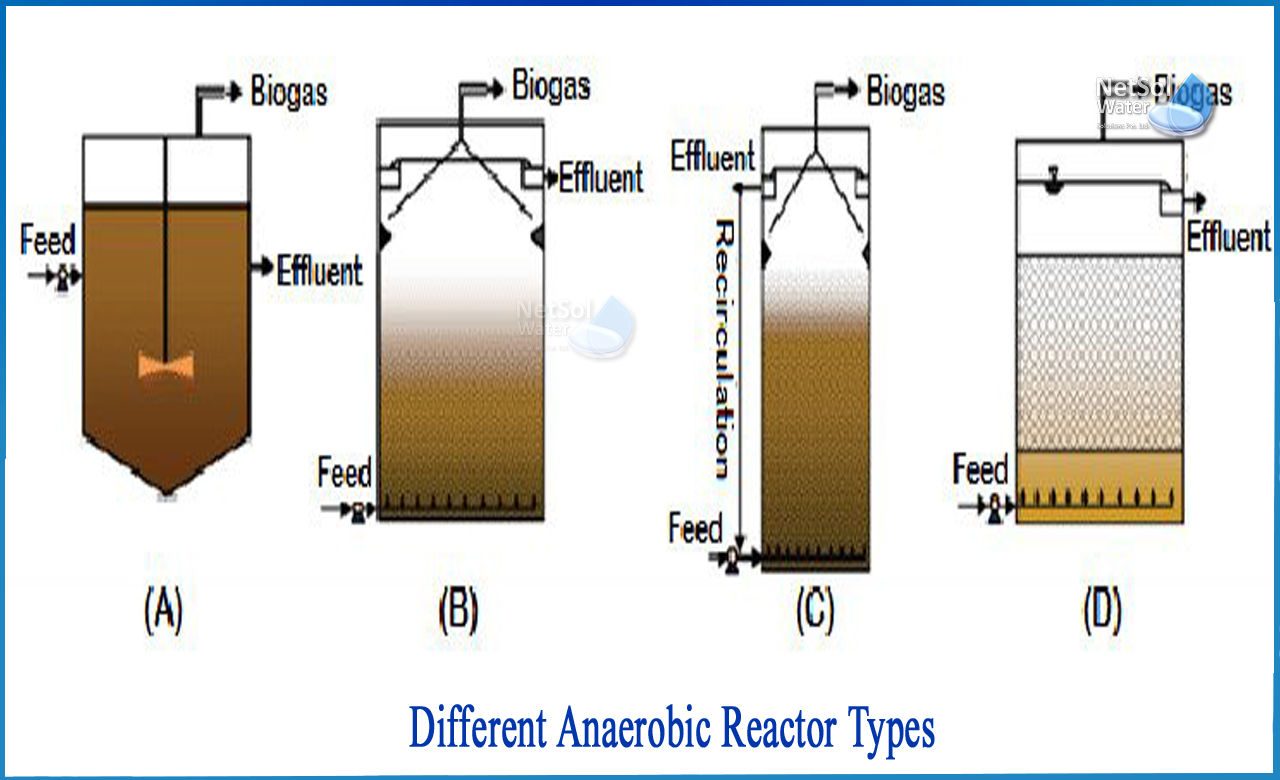

A number of bioreactor configurations are created and developed for anaerobic wastewater treatment, depending on the uses and requirements.

The following are some of the most prevalent types: –

1: Process of anaerobic contact: The recycling process is connected to a series of reactors. The recycled material is pumped to the bottom of the up-flow reactor's initial reactor. A vacuum degasifier is used to separate the gas from the substance leaving it since it is a mixture of solid, liquid, and gas.

2: Anaerobic Filter: These reactors are made up of a tank and fixed filer media such as plastics, gravel, bricks, or other materials. The anaerobic microbes form a biofilm on the filter media, which is known as a biofilm. The effluent in an AF reactor is forced to travel through a filter, exposing it to bacteria. It has a high biosolid retention capacity and is widely employed in the food, pharmaceutical, and chemical sectors.

3: Reactors with fluidized and enlarged beds: Small media, such as sand or granular activated carbon, are used. It's clinging to the germs. Due to mass transfer and a high flow rate around the particles, large biomass can be generated. Fluidized bed reactors are highly efficient due to their tiny size. The Up-flow anaerobic sludge blanket digestion - UASB – is one of the most often used bioreactor types.

4: Up-flow anaerobic sludge blanket reactor (UASB): In anaerobic wastewater treatment, it is one of the most commonly used bioreactor types.

The UASB is a methane-producing anaerobic bioreactor that has grown in popularity. It is widely used for municipal wastewater treatment and industrial wastewater treatment, particularly in the food, chemical, and pulp sectors. Anaerobic bacteria break it down and turn it into granular sludge. A sludge bed and a sludge blanket are used in the treatment process.

The anaerobic bacteria break down the wastewater as it runs upward through the blanket. With the help of flocculants, the blanket is suspended by the upward flow paired with gravity's settling effect. The sludge bed has a high biomass concentration, and substrates move through it. The remaining substrate passes through the sludge blanket, which comprises biomass with a lower density.

The sludge is blanketed, allowing for both solid and hydraulic (liquid) retention time in the digesters. Solids that require a lot of digestion time can stay in the reactors for up to 90 days. Sugars dissolved in a liquid waste stream can be swiftly transformed to a gas in the liquid phase, allowing the system to be closed in less than a day. When the technology is put into service, it must be constantly monitored to ensure that the sludge blanket is not washed out.

Conclusion

Microorganisms must convert organic material to biogas via hydrolysis and acidification for successful anaerobic wastewater treatment.