How does a UASB reactor work?

Upflow Anaerobic Sludge Blanket reactor also known as UASB reactor is a form of anaerobic digester which is used in wastewater treatment based on an upward movement of the liquid waste through a dense blanket of anaerobic sludge.

The UASB reactor is an anaerobic methane-producing digester that creates a blanket of granular sludge that is digested by anaerobic bacteria.

Field of application for UASB reactor

UASB is not suitable for small or rural towns that do not have access to a reliable water supply or electricity. It finds its application in:

• Breweries and beverage manufacturing industries

• Distilleries and fermentation manufacturing industries

• Food manufacturing industries

• Paper and pulp

These four industries are responsible for 87 percent of all applications. However, the technology's uses are fast developing, including:

1. Treatment of effluents from the chemical and petrochemical industries

2. Wastewater from the textile industry

3. Leachates from landfills

4. Metal removal and conversions in the sulphur cycle.

In addition, in hot regions, the UASB idea can be used to treat household wastewater.

Advantages and Disadvantages of UASB Reactor

A: Advantages

i. A significant amount of valuable biogas energy will be produced during the treatment process, which can be collected for other purposes;

ii. Much less bio-solids waste will be generated compared to an aerobic process because much of the energy in the wastewater will be converted to a gaseous form, leaving very little energy for new cell growth;

iii. Low energy requirements for the treatment process;

iv. Less nutrients required;

v. System can be shut down for extended periods without causing damage.

B: Disadvantages

i. Surface water discharge quality cannot be achieved without post-treatment;

ii. Reduced sulphur compounds are formed, which must be carefully addressed in terms of corrosion, odour, and safety;

iii. A longer start-up period is required.

iv. Because the anaerobic procedure requires a specific temperature range (15oC to 35oC), it is not appropriate during the cold season in some places.

v. Professionals and some equipment (such as a pH meter and thermometer) are required to monitor the reactor's internal state. It is costlier.

Working of UASB Reactor

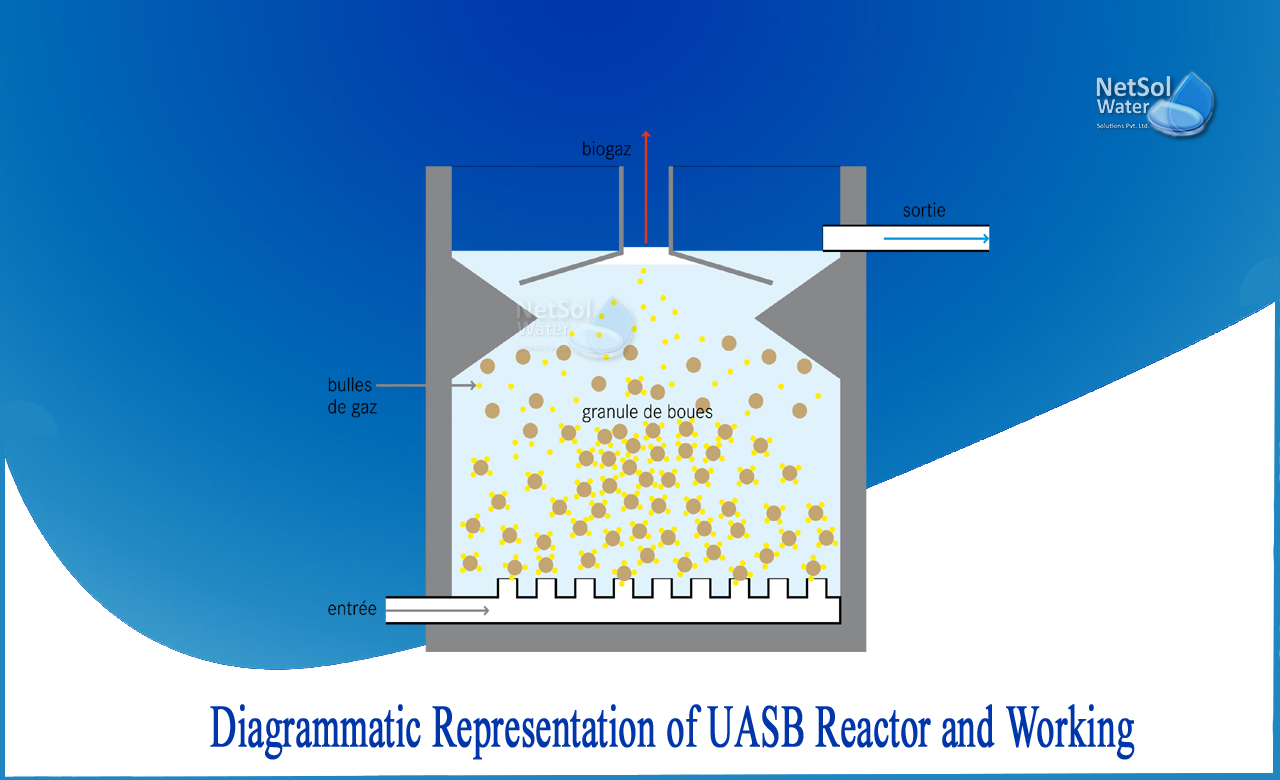

The UASB reactor can be divided in three main parts:

a) Sludge bed,

b) Sludge blanket, and

c) Three phase separator (gas-liquid-solid, GLS separator) provided at the top of the reactor.

Under high turbulence, the three-phase separator allows the reactor to separate gas, water, and sludge mixtures.

Microbial granules (1 to 3 mm in diameter) make up the sludge blanket, which are tiny agglomerations of high concentration of active anaerobic microorganisms that resist being washed out in the upflow due to their weight. Majority of organic substances are degraded by the bacteria in the sludge layer. Gases (methane and carbon dioxide) are released as a result and cause internal mixing in the reactor. The sludge is mixed by rising bubbles without the use of any mechanical equipment. The free gas and particles with the attached gas that reaches the top of the tank is deflected downwards by the slanted walls. The cleared effluent is taken from the tank's top, above the sloped walls.

Larger granules of sludge form over many weeks of use, which act as filters for smaller particles as the effluent rises through the sludge cushion. Granule-forming organisms are preferentially deposited due to the upflow regime, while the others are washed away.The UASB is a centralized treatment technology that requires professional operation and maintenance. A trained operator is necessary to monitor the reactor and fix any malfunctioning equipment, such as pumps.Only extra sludge is removed every 2 to 3 years during desludging.

How can we assist?

Netsol Water is a pure-play technology company that offers a variety of wastewater-related solutions around the world, including resource conservation, optimization, recycling, and reuse.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.