What is Belt Filter for Industrial Wastewater Treatment?

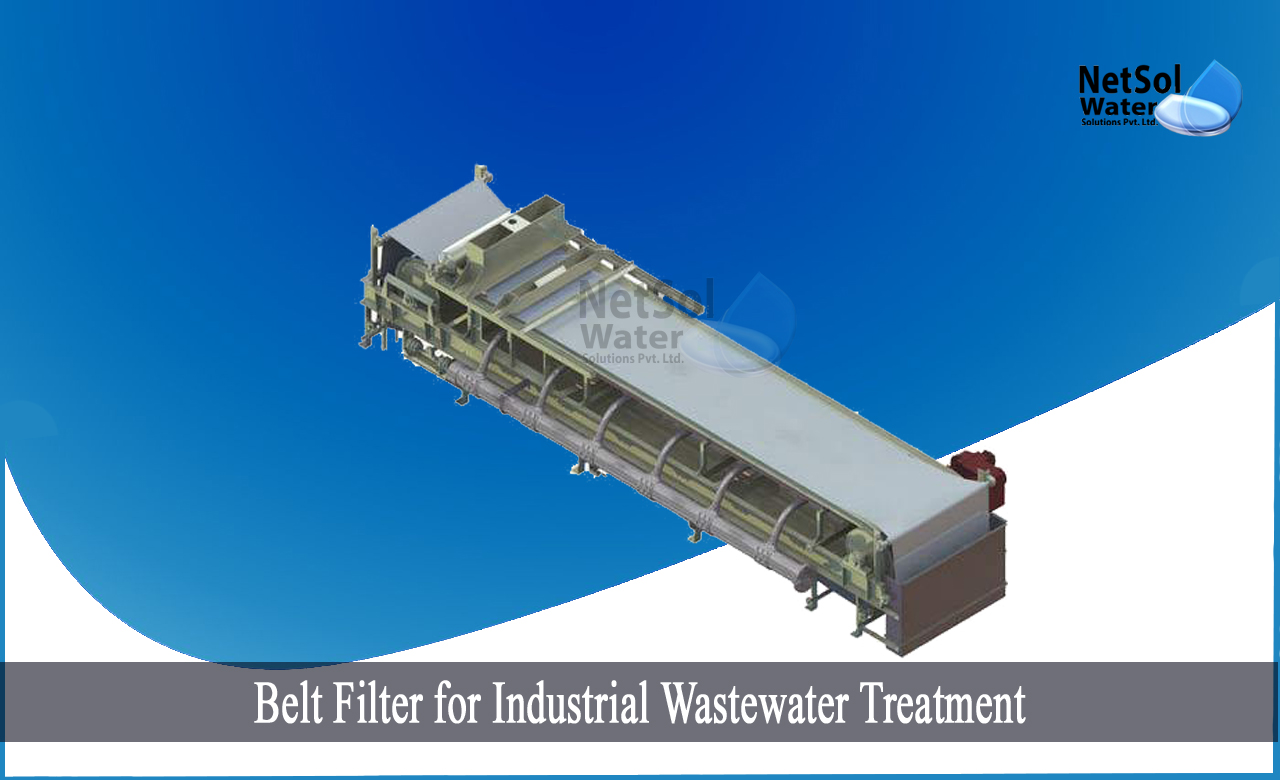

The belt filter is a type of industrial machinery used in solid and liquid separation techniques, including sludge dewatering in water and wastewater treatment sectors. The most common method of filtering is to roll a sequence of filtering belts, or cloth through a roller unit.

To attain a specified dry solid percentage from the slurry or sludge to be treated, belt filters are designed using manufacturer design and quality data, surveys of similar facilities, pilot testing, operating installations, and wastewater solids testing.

Zones of belt filters

The belt filter press's four main zones are as follows:

1: Getting ready for gravity drainage,

2: Linear compression,

3: Compression of a roller,

4: Preconditioned sludge.

Concentration of feed and size of the belt filter

The feed material concentrations determine the gravity drainage surface's size. For feed solids concentrations between 1.5 and 2.5%, a configuration with a larger drainage basin or extended dimension, should be utilized for better unrestricted water drainage, prior to compression. The normal size can be used for solids concentrations of 1.5%.

For diluted sewage with input solids of less than 1.5%, a separate gravity drainage belt could be used. In the pressure and wedge zones, the feed is positioned between two belts that are upper and lower. However, each gravity zone has its own belt, making the belt filter a three-belt system. Depending on the needs of the cake, belt filters may include additional cleaning stages, in addition to infrared, hot gas, or microwave drying stages.

Use of belt filters

Belt filters are quite adaptable and can be used to treat sludges, slurries, etc., for a source or treatment method that produces offensive odours, volatile emissions, infections, or poisonous gases, like hydrogen sulphides.

Features of belt filters

A gas-tight enclosure or fume hoods may completely enclose the belt filter. Due to the restricted visibility and higher corrosion associated with the enclosure, the belt filter process could potentially be automated. Large filtering zones, additional rollers, and variable belt speed, are all features of advanced belt press filter designs.

Working of belt press filters

Belt press filters are designed for solids capacity, rather than wastewater flow. It is necessary to calculate the proportion of primary particles in the feed, as well as any additional solids that may have precipitated during treatment. Since the amount of solids in a process might fluctuate, it is expected that the design will support fluctuating feed solids concentrations.

The flow to a belt press filter is influenced by the types of solids, the desired product, and the filter design. For the majority of sludge types, the feed solids percentage is typically in the range of 1 to 10%. The dewatered sludge typically has a dry solids concentration of between 12 and 50%.

Post-Treatment mechanisms

With belt press filters, a totally clean filtrate can only be attained under unusual circumstances. The filtrate may therefore need additional processing, before it can be recycled or disposed of as waste. The filtrate can be transformed back into the clarifier, if the filter is placed downstream, which lowers the required filtrate clarity and permits the use of more robust cloths.

If re-use or recycling the leftovers is not an option, they must be disposed of in accordance with the laws and licence requirements. Clarified water might need more processing before being released.

Benefits of Belt Filters

Belt filter presses can process a range of sludge types, including diatomite-treated wastewater, oil, etc.

· It is inexpensive energy. Under the same circumstances, the belt filter press produces the same results as some other filter presses, but it does so while consuming less water and less energy.

· Due to its unusual construction, the belt filter press only occupies about half of the available space. When it comes to treatment, it produces the same outcome as the other filter presses.

· The machine's filter belt is incredibly durable and only has a short length. Because of its special structure for adaptability, it is difficult to damage.

· The filter belt does operate consistently and has a great level of durability.

Due to its straightforward construction and respectable design, the belt filter press's operation is also less complicated, than that of other filter presses.

Manufacturers of Wastewater Treatment Plants in India

Netsol Water, based in Greater Noida, India, is a well-known manufacturer of water and wastewater treatment systems. We are well-known for being the top commercial RO plant manufacturers, industrial RO plant manufacturers, ZLD Plant manufacturer, sewage treatment plant manufacturers, Water Softener Plant Manufacturers, effluent treatment plant manufacturers, and much more. Almost all these treatment processes require sludge drying equipment’s. That is why, it is important to consult expert engineers and consultants of wastewater treatment systems.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.