Introduction to UASB reactor

Upflow Anaerobic Sludge Blanket reactor also known as UASB reactor is a form of anaerobic digester which is used in wastewater treatment based on an upward movement of the liquid waste through a dense blanket of anaerobic sludge.

The UASB reactor is an anaerobic methane-producing digester that creates a blanket of granular sludge that is digested by anaerobic bacteria.

Field of application for UASB reactor

UASB is not suitable for small or rural towns that do not have access to a reliable water supply or electricity. It finds its application in:

• Breweries and beverage manufacturing industries

• Distilleries and fermentation manufacturing industries

• Food manufacturing industries

• Paper and pulp

These four industries responsible for 87 percent of all applications.

Parts or components of UASB Reactor

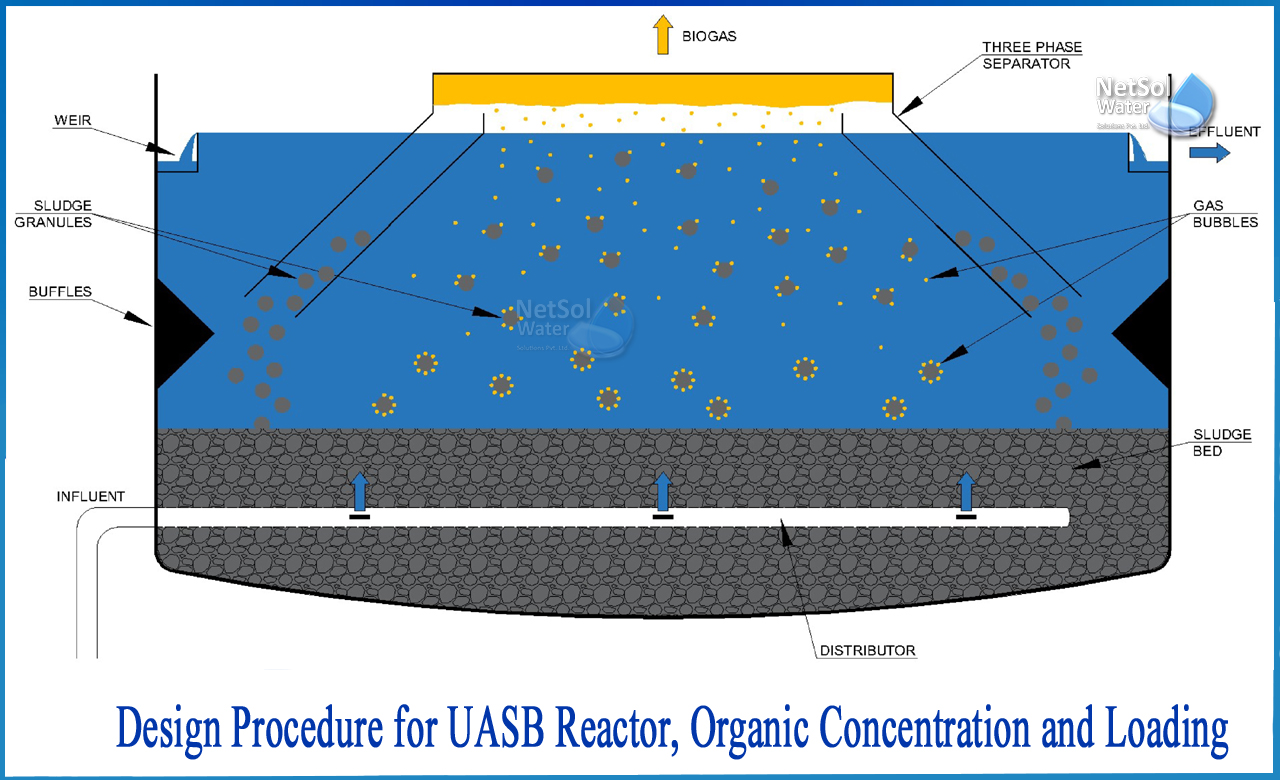

The UASB reactor can be divided in three main parts:

a) Sludge bed,

b) Sludge blanket, and

c) Three phase separator (gas-liquid-solid, GLS separator) provided at the top of the reactor.

Under high turbulence, the three-phase separator allows the reactor to separate gas, water, and sludge mixtures.

Design parameters for UASB reactor

UASB reactor consists of a tank designed as circular or rectangular, where the wastewater flows upwards through a dense sludge bed with high anaerobic microbial activity. The sludge bed occupies about half the volume of the reactor and consists of microbial granules (1 to 3 mm in diameter) or highly sedimentable flocs. The sludge is mixed by rising bubbles without the use of any mechanical equipment. The free gas and particles with the attached gas that reaches the top of the tank is deflected downwards by the slanted walls. The cleared effluent is taken from the tank's top, above the sloped walls. The solids profile in the reactor varies from very dense and granular particles close to the bottom to more dispersed and light particles close to the top.

The wastewater enters the UASB reactor from the bottom, and the effluent exits via a settling zone at the top. It is necessary to select proper range of operating parameters for design such as organic concentration, superficial liquid upflow velocity, reactor volume, hydraulic retention time, etc.

How to Design procedure for UASB reactor for Organic concentration?

Different sorts of effluents are produced when residential wastewater is biologically treated with a UASB reactor. The amounts produced and the characteristics of these effluents are estimated considering the influent to be treated.

The anaerobic treatment with UASB reactors usually achieves removal efficiencies of 70-80% of the COD and TSS content. For COD concentration in the range of 2 to 5 g/L, the performance of the reactor depends upon the loading rate and is independent of the concentration of influent substrate. After the reactor's main start-up when sludge granulation is complete, loading rates can be gradually raised to bring the real COD content of the wastewater to the desired level.

The loading above 1 - 2 kg COD/ m3.day is essential for proper functioning of the UASB reactor. For low temperatures, a lower OLR should be used, whereas for hot temperatures, a higher OLR can be used.The reactor may be built to load between 1.5 and 18 kg COD/ m3.d at temperatures between 15 and 350C.

The classification of wastewater based on COD content is required in order to generalize the UASB reactor design technique and satisfy the specified operating parameters to the greatest degree possible.

As a result, the COD content in wastewater may be split into four categories:

i) Low strength (COD upto 750mg/L): Recommended loading range 1.0-3.0Kg COD/m3.d

ii) Medium strength (COD 750-3000mg/L): Recommended loading range 2.0-5.0Kg COD/m3.d

iii) High strength (3000-10,000 mg/L): Recommended loading range 5.0-10Kg COD/m3.d

iv) Very high strength (> 10,000 mg/L): Recommended loading range 5.0-15Kg COD/m3.d

How can we assist?

Netsol Water is a pure-play technology company that offers a variety of wastewater-related solutions around the world, including resource conservation, optimization, recycling, and reuse.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.