What is the recommended Design of PST?

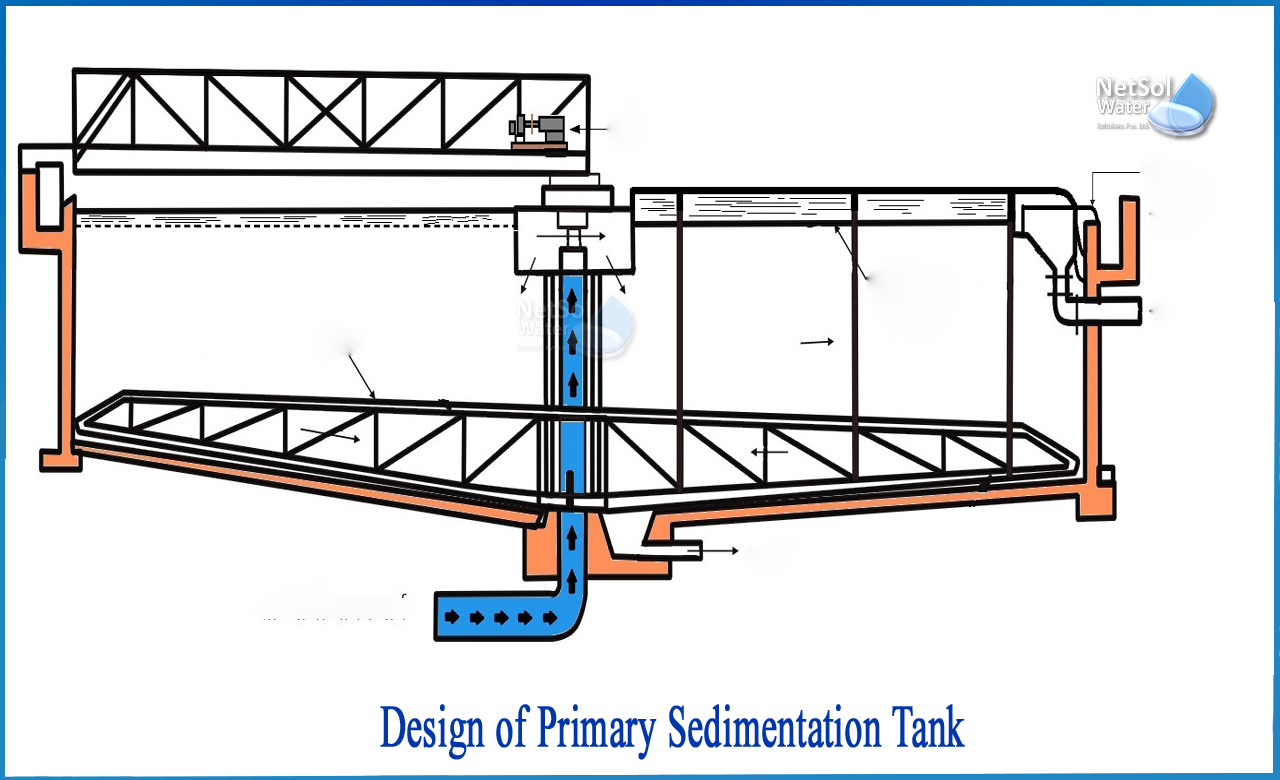

Primary sedimentation tanks receive wastewater that have already received pretreatment. Settling particles present in water or wastewater (as suspended solids have specific gravity greater than that of water) have the tendency to settle down under the influence of gravity as soon as effect of turbulence retards. Flow is retarded in a basin called as settling tank.

These settling tanks are designed on the basis of average dry weather flow and checked for peak flow condition. Tanks can be circular or rectangular.

Design Considerations for PSTs

1. The diameter of circular tank may range from 3 to 60 m.

2. Rectangular tanks are used but length more than 40 m is not preferred.

3. Width of the tank depends on the size of the scrappers available.

4. The depth of tank should be as shallow as possible, with minimum 2.15 m. The average depth of the tank used is about 3.5 m. An addition of 0.25 m for sludge zone and 0.3 to 0.5 m free board is provided.

5. Slope of 6 to 16 % for circular tanks and 2 to 8% for rectangular tanks is provided to the floor of the settling tank.

6. The scrappers are provided to collect the solids in a sump and the solids are removed regularly in circular tanks.

7. The solids are collected in rectangular tanks, in the sludge hoppers at the influent end. These are taken out at fixed time intervals.

8. The velocity of scrapper is 0.6 to 1.2 m/min in rectangular tanks and speed of 0.02 to 0.05 rpm is maintained in circular tanks.

9. Arrangement for scum removal is provided ahead of the effluent weir in all the PSTs.

10. The surface overflow rate of 40 m3 /m2 .d is used for design at average flow. At peak flow when this PST is followed by secondary treatment, the surface overflow rate of 80 to 120 m3 /m2 .d could be used.

11. The weir loading rate of less than 185 m3 /m.d is used for designing effluent weir length.Higher weir loading can be used when primary treatment is followed by secondary treatment.

12. The detention time in PST could be as low as 1 hour to maximum of 2.5 hour. To avoid scouring, horizontal velocities through the PST should be kept low.

To get a better understanding about the design details,

Let us consider an example for design of primary settling tank to treat wastewater with average flow rate of 10 MLD and peak flow of 22.5 MLD.

Assume surface settling rate = 50 m3/m2.d

Therefore, the surface area of the tank = 10 x 106 / 50 x 103= 200 m2

Check for peak flow condition:

The SOR at peak flow = 22.5 x 103/200 = 112.5 m3/m2.day

This value is less as compared to the recommended value at peak flow.

Assume width = 4.0 m

Therefore theoretical length = 200/4 = 50m > 40 m

Hence, provide two tanks in parallel.

Total length of each tank = 50/2 + 2 (inlet) + 2 (outlet) = 29.0m

Now,

Flow rate x detention time = tank depth x surface area = volume of tank

Or, Flow / Surface area = tank depth / detention time = Surface settling rate

Provide detention time of 1.2 h

Therefore, liquid depth required = 50 x 1.2 / 24 = 2.5 m

Therefore, flow through velocity = (0.116 m3/sec) / (2 x 2.5 x 4)

= 0.0058 m/sec < 1 cm/sec

That is O.K.

At peak flow,

Flow through velocity = 22.5 x 103/(2 x 4 x 2.5) = 1125 m/d = 0.00130 m/sec.

(Horizontal velocity should be less than non-scouring velocity i.e. less than 0.06 m/sec.)

Provide total depth = 2.5 + 0.5 (free board) + 0.25 (space for sludge) = 3.25 m

Weir loading rate = 10 x 103/ 12 = 833.33 m3/m.d> 185 m3/m.d

Required length of weir = 10 x 103 / 185 = 54.05 m

Hence, provide about 29 m of weir length for each tank. Two effluent collection channels at outlet end offering total 24.0 m and side weir of total 1.55 m on each side can be provided.

Conclusion

Netsol Water is one of the leading water and wastewater treatment company in India with services in the field of WTP manufacturing, WWTP manufacturing, STP manufacturing, ETP manufacturing, among other services. The company designs and manufactures machines and is dedicated to practical solutions that spur business growth and simultaneously preserves world’s most precious resource- WATER!

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.