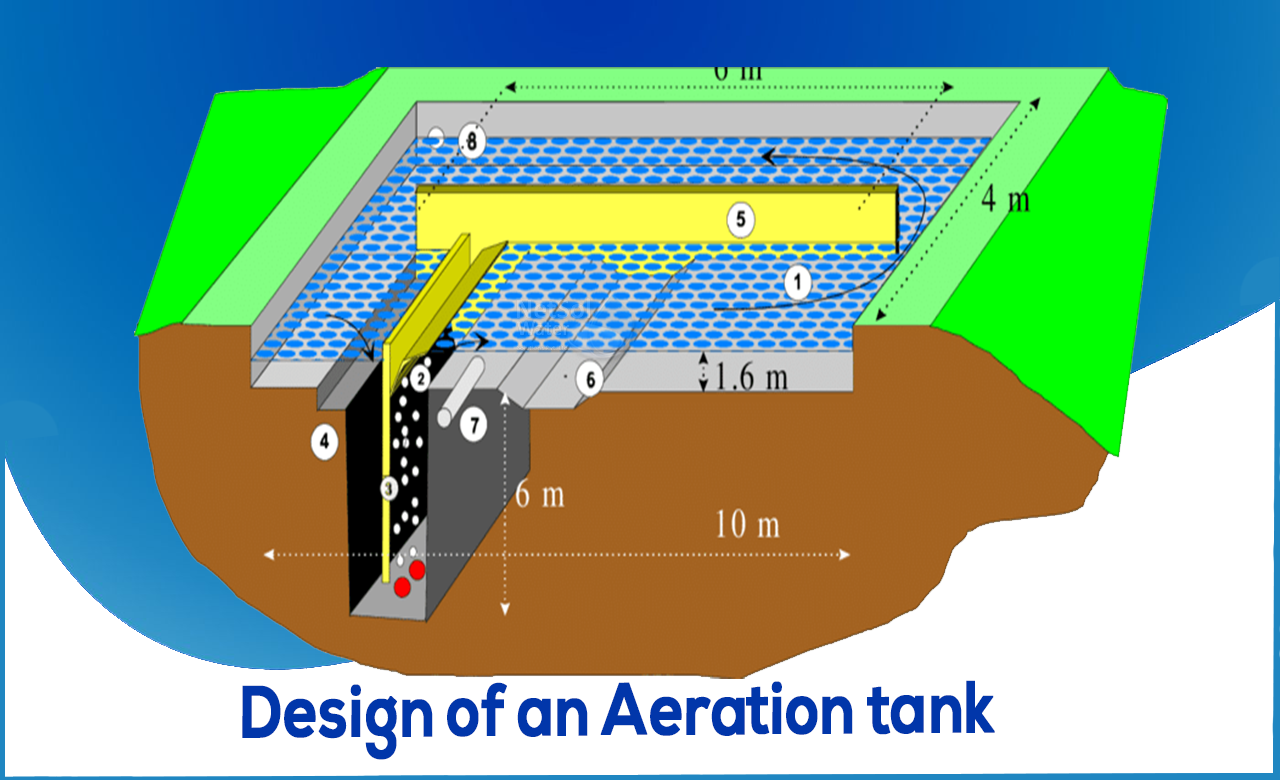

Design of an Aeration Tank

Step aeration introduces settled sewage at multiple spots along the tank's length, resulting in a more consistent oxygen demand. Tapered aeration tries to match air supply to oxygen demand along the tank's length. Contact stabilisation enables for the re-aeration of activated sludge from the last clarifier, allowing for a smaller aeration or contact tank.

The goal of the completely mixed process is to mix the influent trash and return sludge with the whole contents of the aeration tank in real time. The extended aeration method works with a low organic load, resulting in a less amount of well-stabilized sludge.

Consideration in the Design of Aerated Tank

Aeration tank capacity and dimensions, aeration facilities, secondary sludge settling and recycling, and excess sludge squandering are all factors to consider while designing an aeration tank facility.

Steps followed in the design of an aeration tank

By assuming an acceptable value of MLSS concentration X, the volume of the aeration tank is computed for the given value of θc.

VX = YQθc(SO - S) 1+ kdθc

Alternately, the tank capacity may be designed from

F/M = QSO / XV

As a result, the first stage in planning is to select a reasonable value ofθc (or F/M), which is determined by the projected winter temperature of mixed liquor, reactor type, sludge settling characteristics, and nitrification requirements. When nitrification and good BOD removal are sought, complete mixing systems are used. The choice normally ranges from 5 days in warmer areas to 10 days in temperate countries.

The next step is to choose two interconnected parameters: HRT, t, and MLSS concentration.

It can be observed that assuming a large value of X can result in a reduction in reactor volume. It is rarely taken to be greater than 5000 g/m3. If a traditional plug flow type aeration system is supplied, the MLSS value for ordinary home sewage is 2000-3000 mg/l, or 3000-5000 mg/l for entirely mixed types.

What influence the upper limit of an aeration tank?

Initial and running costs of a sludge recirculation system to maintain a high value of MLSS, limitations of oxygen transfer equipment to supply oxygen at required rate in small reactor volume, increased solids loading on secondary clarifier, which may necessitate a larger surface area, design criteria for the tank, and minimum HRT for the aeration tank are all factors that influence the upper limit.

What determines the length of the tank?

The tank's length is determined by the type of activated sludge plant. Aeration tanks are constructed as long narrow channels, with the exception of extended aeration plants and entirely mixed plants.

What determines the width and depth of the tank?

The aeration tank's width and depth are determined by the type of aeration equipment used. Aeration efficiency is controlled by the depth, which typically varies from 3 to 4.5 metres. The mixing is controlled by the breadth, which is normally kept between 5 and 10 metres. The width-to-depth ratio should be between 1.2 and 2.2. The length should not be less than 30 metres and should not exceed 100 metres.

Oxygen Requirements

In the activated sludge process, oxygen is required for the oxidation of a portion of the influent organic waste as well as the endogenous respiration of the microorganisms. The following calculation can be used to calculate the total oxygen requirement of the process:

O2 required (g/d)= Q(So-S)/f-1.41 QwXr

Where,

“f” is the ratio of BOD-5 to final BOD and 1.42 is the biomass oxygen demand (g/g).

The formula does not allow for nitrification and only provides for the removal of carbonaceous BOD.

For more information, we at Netsol Water Solutions are here to help.