What exactly is an effluent treatment plant?

An Effluent Treatment Plant is a wastewater purification method that is specifically intended to purify industrial wastewater where it undergoes treatment for recycling or safe disposal to the ecosystem using a variety of techniques. This method lowers the requirement for fresh water while maintaining the environment clean.

Why Is Phosphorus an Issue in Wastewater?

Phosphorus (P) is a necessary microelement for plant and algae development, but its abundance as phosphate (PO43) in aquatic environments can lead to eutrophication and degradation of the condition of the water. Phosphate levels in the water may lead to algae blooms and a decrease in dissolved oxygen, both of which are detrimental to aquatic life. Human behaviors such as the incorporation of animal waste and fertilizer to soil, as well as the release of industrial, household, and farming wastewater, contribute to the phosphate fortification of surface waters.

For phosphate removal from water or wastewater, various physical, chemical, and biological methods have been proposed, including anion exchange, sorption, chemical precipitation, membrane nanofiltration, reverse osmosis, electrodialysis, and biological eliminating via designed wetland, activated sludge, and microalgal systems.

Design Effluent Treatment Plant for phosphating plant

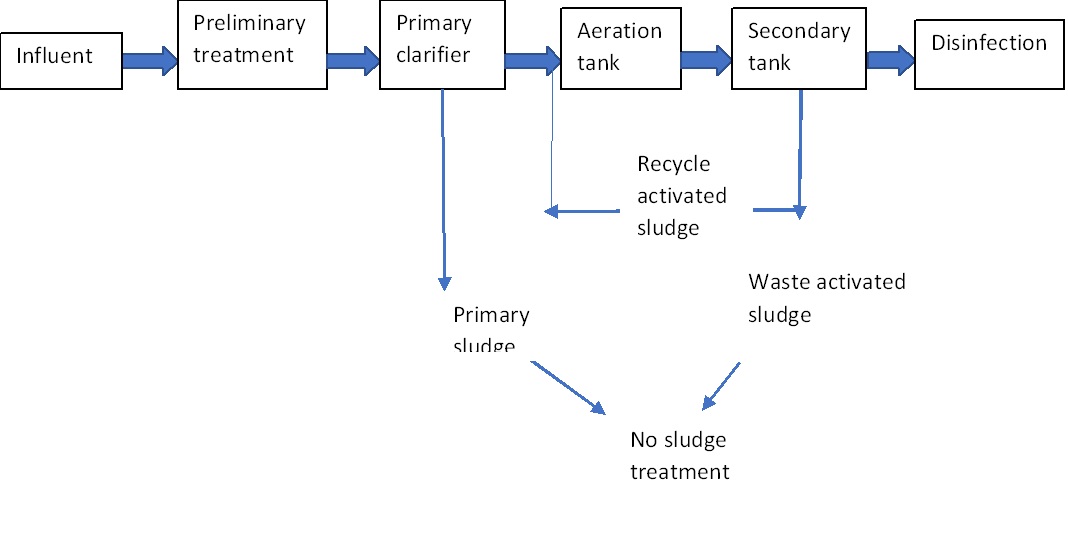

Depending on the degree of treatment needed, effluent can be treated in a variety of methods. The terms preliminary, primary, secondary, and tertiary refer to these stages. (or advanced). There are three general categories of treatment mechanisms: physical, chemical, and biological, each of which includes a variety of distinct processes. In a single treatment facility, many of these procedures will be used simultaneously.

Preliminary treatment:

This is the first stage in the treatment of wastewater, and its aim is to eliminate heavy inorganic substances, large debris, and coarse particles from the wastewater. Screening, floatation, and grit removal are among the common physical unit operations.

Scre?ening: To filter out large solids like cloth that could harm processing machinery, lessen the efficacy of the ETP, or contaminate waterways, use a screen with uniformly sized openings.

Floata?tion: This technique is used to remove floating and dispersed solids from wastewater.

Grit re?moval: In this case, the flow is slowed down with the help of grit chambers so that solids like sand, ash, cinder will settle out of the water and can be removed manually or automatically.

Primary treatment:

The primary treatment activities are intended to remove settleable organic and inorganic solids by sedimentation, and the large debris and grit removed during the preliminary treatment are directed there.

Sedimentation is accomplished in a tank known as the clarifier, settling tank, or sedimentation tank. It is also used to make clarified effluent, eliminate grit and suspended solids, and thicken the sludge created during biological treatment. Most of the suspended solids and a fraction of the BOD should be eliminated by flocculation and sedimentation.

Secondary treatment:

The goal of this treatment, which includes a biological process, is to further treat the effluent from the primary treatment to remove any remaining organic materials and suspended solids. Although biological treatment methods can take various forms, they are all centered on microorganisms, primarily bacteria. These microbes use the effluent's constituent parts as their "food," breaking them down into simpler and less dangerous compounds as a result. The quantity of microorganisms grows during the process. There are two major categories of processes: those involving attached and suspended microbial growth (such as activated sludge). In both methods, significant numbers of microorganisms are exposed to effluent while an excess of oxygen is present. Both methods require that the microbial population be kept in a tank known as the reactor. Microbes that use suspended growth systems congregate into tiny "flocs." (This is known as activated sludge). In order to recycle the microbes, activated sludge (AS), along with the treated effluent, is settled out in a clarifier and sent back to the aeration unit. If there is too much AS, some may need to be thrown off rather than recycled.

Advanced treatment:

The primary goal of this final treatment step in the wastewater processing process is to remove particular wastewater constituents that could not be removed in earlier stages, thereby improving the quality of the effluent to a greater extent. It makes use of some kind of filtering to get rid of more suspended solids than primary, secondary, and sedimentation could handle. This procedure eliminates nutrients, heavy metals, particular toxic chemicals, and other pollutants and contaminants. It may rid sewage of more than 99% of all impurities, resulting in effluent with nearly drinking-water purity. It requires disinfection, which is accomplished using both chemical disinfectants like chlorine and physical disinfectants like UV radiation.

Working of ETP in phosphate plant

Do you need an advice o?r assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us now your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com