An industrial air-blower is a machine that increases air flow by the use of an electrical motor, impeller, and air foils extremely quickly and effectively. These blowers are designed to be a long-term addition to a room, extending air flow and removing impurities like dust, grime, and particulates. These are made to deliver increased pressure at a quantitative relation between 1 and 1.2.

How to design air-blowers in Sewage treatment plants?

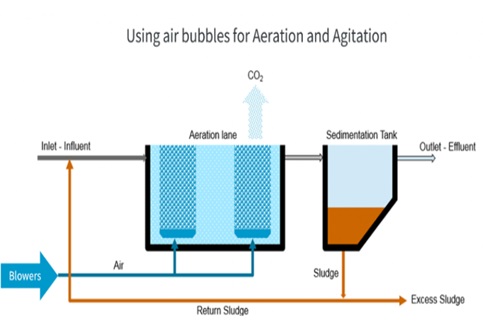

Aeration and agitation are the two main activities that are served by air bubbles, which are primarily produced by air blowers during the secondary phase of treatment.

The main goal of aeration is to supply the biological activities with useable oxygen. This makes it possible to maintain microbe concentrations that are greater.

Let’s understand the various design considerations for air blowers in STPs.

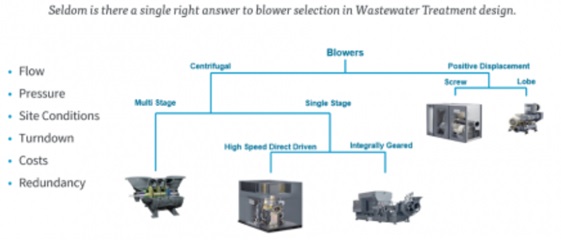

· Flow

The first step in selecting a suitable sewage air blower is to determine the system's required flow. It is decided on the basis of how much oxygen the microorganisms in the treatment system need. The amount of oxygen needed in the sewage stream depends on the metabolism of the organic material, the effectiveness of oxygen exchange in the tank, and the site conditions.

The waste, microbes, and oxygen (O2) used in the metabolism of the organic material produce carbon dioxide (CO2), ammonia, and the energy required to develop other bacteria. Ammonia, bacteria, and oxygen are transformed into nitrous oxide, water, and further microbes in a subsequent process.

· Pressure

A standard cubic feet per minute (SCFM) requirement for the system can be calculated, using samples and an engineering calculation based on the biological oxygen demand, ammonia levels, and oxygen transfer efficiency.

When examining SCFM, keep in mind that this is a mass flow and will fluctuate with the surrounding pressure and temperature. For instance, heated air has less oxygen per cubic foot than colder air. This means that in order to determine actual flow rates for the product and application, calculations must at the very least take into account the elevation of the site, and the high and low ambient temperatures.

· Blower Size

The projected pressure of the system will be a second factor in the blower sizing. When a blower is rated at 17 pounds per square inch (psi), it can actually overcome a maximum level of system backpressure.

This depends on the blower's motor power; the more the motor power, the greater the pressure that can normally be applied to the pipe.

· Site Conditions

The choice of blower will also be heavily influenced by site conditions. Positive displacement and multistage centrifugal units often perform better in tougher settings and outdoor use, whereas high speed turbos and integrally geared centrifugal units are typically, better suited for interior or cleaner applications.

· Turndown

It is another important element. A sewage treatment plant cannot be efficiently accommodated by using a single fixed-speed blower, to produce consistent airflow since nothing in the sewage treatment process is ever in a stable state. Inflow has peaks and valleys, and a system that is well-designed will be able to adapt to these fluctuations.

· Costs

Blowers used in sewage treatment typically have an overall cost of ownership, which is dominated by energy costs. The blower should match the flow to demand in order to provide energy savings.

A sewage treatment facility frequently has a maximum to minimum flow ratio of at least 10:1.

· Redundancy

In sewage treatment, aeration levels are typically five to seven times higher than they would be in nature. If suddenly there is not enough oxygen present, the bacteria will start to die right away. System operators cannot take that chance because it can take days or weeks, for sewage treatment systems to stabilize.

In order to provide some level of redundancy that permits the process to continue, in the event that a blower needs maintenance or replacement, sewage treatment plants often incorporate numerous blowers.

How can we assist?

Netsol Water is the best manufacturer of water and wastewater treatment plants in India. We provide advanced treatment methods in sewage treatment plants and effluent treatment plants, including MBR, MBBR, SBR, etc.

With the help of innovation and market expertise, we can design and provide air blowers for sewage treatment plants. For further information, contact us at +91 9650608473 or email at enquiry@netsolwater.com