How to design Sewage Treatment Plant for Railway Stations in India?

India has one of the largest railway networks in the world, with millions of passengers traveling every day. Railway stations are an essential part of this network, and they generate a significant amount of sewage that needs to be treated before discharge. Sewage treatment plants (STPs) are a critical component in ensuring the safe disposal of wastewater from railway stations.

In this blog, we will discuss how to design an STP for railway stations in India, including design calculations, process flow diagrams, and detailed working functions.

Design Calculation:

The design of an STP for railway stations is based on the quantity and quality of sewage generated. The sewage flow rate is calculated based on the number of passengers using the station per day. The average water consumption per person is considered to be 135 liters per day, with 80% of this being sewage. Therefore, the sewage flow rate can be calculated using the following formula:

Sewage flow rate = Number of passengers x 135 x 0.8

Once the sewage flow rate is determined, the plant's capacity can be calculated based on the required treatment efficiency. The Central Pollution Control Board (CPCB) has set the following standards for treated sewage discharge from railway stations:

- Biological Oxygen Demand (BOD) ≤ 30 mg/l

- Suspended Solids (SS) ≤ 30 mg/l

- Total Coliforms (TC) ≤ 5000 MPN/100 ml

The design capacity of the STP is calculated based on these standards and the sewage flow rate. Typically, the STP capacity is designed to treat 80-90% of the sewage generated.

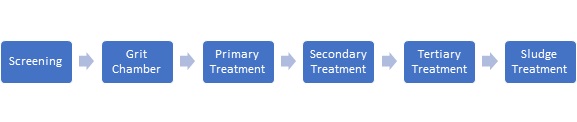

Process Flow Diagram:

The process flow diagram of an STP for railway stations consists of the following stages:

Working Function:

The working function of an STP for railway stations is as follows:

- Sewage is collected from the railway station and transported to the STP.

- The sewage is screened to remove large objects and then passed through a grit chamber to remove sand and gravel.

- The sewage is then passed through a primary settling tank, where solids settle at the bottom, and the lighter solids float to the surface.

- The effluent from the primary settling tank is then treated in a biological reactor, where bacteria and other microorganisms break down organic matter and remove nutrients.

- The effluent from the biological reactor is then passed through a tertiary treatment stage, where disinfection is carried out using chlorine or UV radiation.

- The treated water is then discharged into a nearby water body, or it can be used for non-potable purposes such as irrigation, gardening, or flushing.

- The sludge generated during the primary and secondary treatment stages is thickened and d ewatered using sludge digesters and sludge drying beds.

- The dewatered sludge can be used as a soil conditioner or fertilizer, or it can be disposed of in a landfill.

- The STP is monitored regularly to ensure that the treated water meets the CPCB standards for discharge.

Conclusion:

Designing an STP for railway stations in India is essential to ensure the safe disposal of wastewater and prevent environmental pollution. The design calculation, process flow diagram, and working function of the STP discussed in this blog provide a comprehensive understanding of how to design an efficient STP for railway stations. The use of STPs will help to promote sustainable practices and ensure that the railway stations operate in an environmentally responsible manner.

For any other support, inquiries, or product purchases, call on +91-9650608473 or email at enquiry@netsolwater.com