Design an ETP for biscuit manufacturing with help of a process flow diagram and working function

How to design an ETP for a biscuit manufacturing unit?

As the world's population continues to grow, so does the demand for food, which has resulted in an increase in food processing industries such as biscuit manufacturing. However, along with this growth comes an increase in the amount of wastewater generated by these industries. The discharge of untreated effluent can have significant environmental impacts, which is why it is essential to have an Effluent Treatment Plant (ETP) to treat this wastewater before it is released into the environment.

In this blog, we will discuss how to design an ETP for a biscuit manufacturing unit with the help of a process flow diagram and working function in detail.

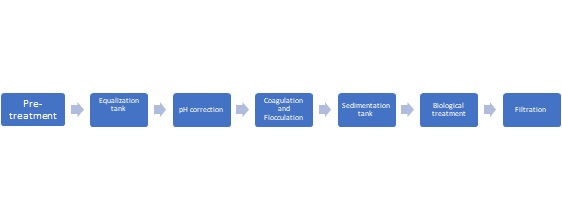

Process Flow Diagram for Effluent Treatment Plant

The process flow diagram for an ETP for a biscuit manufacturing unit is shown below:

Working Function of Effluent Treatment Plant

The working function of an ETP for a biscuit manufacturing unit is as follows:

- Pre-treatment: The pre-treatment process involves the screening of the wastewater to remove any large particles or solids that may be present in the wastewater. The wastewater is then passed through a grit chamber to remove any sand, gravel, or other heavy materials.

- Equalization tank: The equalization tank is used to collect the screened wastewater and mix it to ensure uniformity of the effluent. The equalization tank also helps to regulate the flow rate and load of the wastewater.

- pH correction: The pH correction process involves adjusting the pH level of the wastewater to ensure efficient treatment in subsequent treatment processes. The pH of the wastewater needs to be maintained within a specific range to avoid any adverse effects on the microorganisms used in the biological treatment process.

- Coagulation and Flocculation: In the coagulation process, a coagulant is added to the wastewater, which neutralizes the negative charge of the suspended solids and causes them to come together into larger particles called flocs. In the flocculation process, a flocculant is added to the wastewater, which helps to further aggregate the suspended solids into larger flocs.

- Sedimentation tank: The flocs formed in the coagulation and flocculation process are then passed through a sedimentation tank. The flocs settle to the bottom of the tank due to gravity and form a layer of sludge, which is removed from the bottom of the tank and sent for further treatment.

- Biological treatment: In the biological treatment process, the wastewater is passed through an aeration tank, where microorganisms break down the organic matter present in the wastewater. The microorganisms require oxygen to perform this process, which is supplied through diffusers placed at the bottom of the tank. The organic matter is converted into carbon dioxide and water in this process.

- Secondary sedimentation tank: The treated wastewater is then passed through a secondary sedimentation tank, where any remaining suspended solids and microorganisms settle to the bottom of the tank.

- Filtration: In the final step of the treatment process, the treated wastewater is passed through a sand filter to remove any remaining suspended solids or microorganisms. The filtered water is then disinfected and discharged into the environment.

Conclusion

Effluent treatment is a crucial process in the food processing industry, particularly in biscuit manufacturing units, where significant amounts of wastewater are generated. An effective ETP can ensure that the wastewater is treated to an acceptable standard before it is discharged into the environment. The process flow diagram and working function described above provide a general idea of how an ETP for a biscuit manufacturing unit works. However, the design of an ETP will vary depending on the specific characteristics of the wastewater generated in each industry. It is essential to consult with experts in the field to design and operate an effective ETP that meets local regulatory standards and protects the environment.

Contact us on +91-9650608473 or send an email to enquiry@netsolwater.com to find out more.