How to design ETP Plant for Quinoa Processing or Manufacturing?

Any manufacturing sector must have an effluent treatment plant (ETP) to guarantee that wastewater produced during the manufacturing process is treated before it is released into the environment. Here we'll use a process flow diagram to understand designing of an effluent treatment plant for quinoa processing and manufacturing and go into detail about how it works.

Quinoa and its wastewater:

Quinoa is a cereal crop which is grown for its edible seeds, which are gluten-free, high in protein, and contain essential amino acids. Quinoa processing involves several stages, such as cleaning, grading, dehulling, polishing, and packaging. The wastewater generated during these stages contains high amounts of organic matter, suspended solids, and nutrients, which require proper treatment before discharging it into the environment.

Process Flow Diagram:

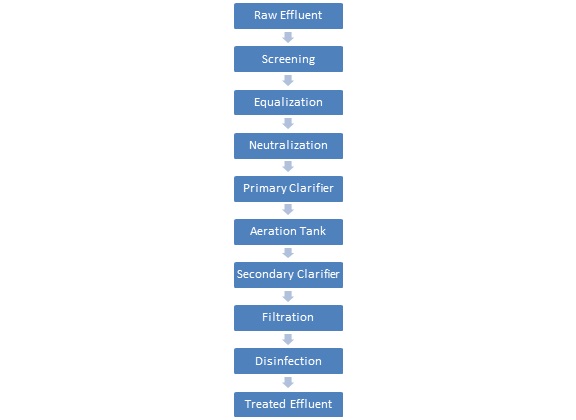

The process flow diagram for the ETP for Quinoa processing is shown below:

Working Functions of Effluent Treatment Plant:

The ETP for Quinoa processing consists of several unit operations, each with a specific function. The working functions of each unit operation are explained below:

1. Screening:

The first unit operation in the ETP is screening, which involves removing large-sized particles and debris from the wastewater. It is done using a mechanical screen, which consists of a rotating drum with perforations. The wastewater is passed through the screen, and the larger particles are retained on the drum's surface and removed manually.

2. Equalization:

The equalization tank is used to balance the flow of wastewater and reduce fluctuations in the influent's quality. It helps in maintaining a consistent wastewater flow rate and pH, which is crucial for the subsequent treatment processes.

3. Primary Sedimentation:

In the primary sedimentation tank, the suspended solids and organic matter are allowed to settle by gravity. The tank's design should allow for a residence time of 1-2 hours to ensure complete sedimentation of the solids. The settled sludge is then removed using a sludge scraper and sent to the sludge treatment process.

4. Aerobic Biological Treatment:

The effluent from the primary sedimentation tank is then treated using an aerobic biological treatment process. The process involves passing the wastewater through an aeration tank, where aerobic bacteria break down the organic matter into simpler compounds. The aeration tank is equipped with diffusers or mechanical aerators to provide oxygen to the bacteria. The residence time in the aeration tank should be between 24-48 hours to ensure complete degradation of the organic matter.

5. Secondary Sedimentation:

In the secondary sedimentation tank, the treated wastewater from the aeration tank is allowed to settle, and the suspended solids are removed. The settled sludge is then removed using a sludge scraper and sent to the sludge treatment process.

6. Disinfection:

The effluent from the secondary sedimentation tank is disinfected using chlorination or UV disinfection to kill any remaining bacteria and viruses. The disinfection process ensures that the treated wastewater meets the effluent discharge standards set by the regulatory authorities.

7. Sludge Treatment:

The sludge generated during the primary and secondary sedimentation tanks is treated using sludge thickening, digestion, and dewatering processes. The thickened sludge is sent to the anaerobic digester, where it is further treated using bacteria to reduce the sludge volume and stabilize the organic matter. The digested sludge is then dewatered using a belt filter press or centrifuge to remove the excess water and generate a dry sludge cake.

Summary:

In order to reduce the environmental impact of processing quinoa while guaranteeing regulatory compliance, an effective ETP must be designed and implemented. The ETP can assist in ensuring the sustainability of the quinoa production business while safeguarding the environment and general welfare via careful planning and implementation.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.