Design a 1000 LPH RO plant for a school and discuss the design basis

Access to clean and safe drinking water is crucial for the health and well-being of individuals. It is especially important for schools to ensure that their students have access to clean water. To meet this requirement, schools can install a Reverse Osmosis (RO) plant.

In this blog, we will design a 1000 liters per hour (LPH) RO plant for a school and discuss the design basis, process flow diagram, and working function in detail.

Design Basis:

Before designing an RO plant, it is important to determine the design basis. The design basis includes factors such as the quality of feed water, the required output, and the type of membrane to be used. In this case, we will assume that the feed water is of average quality with a TDS (Total Dissolved Solids) of 500 ppm (parts per million) and the required output is 1000 LPH. The type of membrane to be used will be a spiral wound membrane.

Process Flow Diagram:

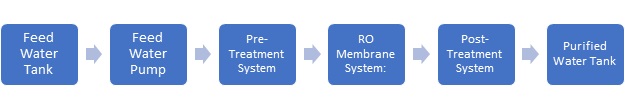

The process flow diagram (PFD) is a schematic representation of the major equipment and the flow of water in the RO plant. The PFD for a 1000 LPH RO plant for a school is shown below.

The PFD shows the following major equipment:

- Feed Water Tank: This tank stores the feed water and supplies it to the RO plant.

- Feed Water Pump: This pump pressurizes the feed water and sends it to the RO plant.

- Pre-Treatment System: The pre-treatment system includes a sand filter, activated carbon filter, and dosing system. The sand filter removes suspended solids and the activated carbon filter removes chlorine and other organic compounds. The dosing system adds chemicals to adjust the pH of the water and prevent scaling and fouling.

- RO Membrane System: The RO membrane system includes a high-pressure pump, pressure vessel, and spiral wound membrane. The high-pressure pump pressurizes the water and sends it to the pressure vessel, where the water passes through the membrane and the purified water is collected.

- Post-Treatment System: The post-treatment system includes a UV sterilizer and a mineral cartridge. The UV sterilizer disinfects the water and the mineral cartridge adds essential minerals to the purified water.

- Purified Water Tank: This tank stores the purified water and supplies it to the school.

Working Function:

The working function of the RO plant can be explained in the following steps:

- Feed water is stored in the feed water tank and is pressurized by the feed water pump.

- The pressurized water is sent to the pre-treatment system, where it undergoes pre-treatment processes such as sand filtration, activated carbon filtration, and dosing to adjust the pH.

- The pre-treated water is sent to the RO membrane system, where it passes through the spiral wound membrane. The membrane separates the water into two streams: permeate and concentrate. The permeate is purified water that passes through the membrane and is collected in the purified water tank. The concentrate is the remaining water that does not pass through the membrane and is sent to drain.

- The purified water from the purified water tank is sent to the post-treatment system, where it undergoes UV sterilization and mineralization.

- The purified and mineralized water is stored in the purified water tank and is supplied to the school for consumption.

Conclusion:

A 1000 LPH RO plant can provide clean and safe drinking water to a school. The design basis, process flow diagram, and working function of the RO plant have been discussed in detail in this blog. The RO plant requires regular maintenance and monitoring to ensure that it is functioning properly and providing safe drinking water.

For any other support, inquiries, or product purchases, call on +91-9650608473 or email at enquiry@netsolwater.com