Design 1000 LPH Commercial RO Plant for Restaurants

Commercial RO Plant (RO) is a water purification technology which employs a semi-permeable membrane. This membrane technology does not exactly serve as a filtration technique. In reverse osmosis, osmotic pressure—a collaborative feature driven by chemical potential, a thermodynamic parameter—is overpowered by an applied pressure. Reverse osmosis, which is utilized in both industrial operations and the creation of drinkable water, may filter out various kinds of molecules and ions from solutions using a semi-permeable membrane.

In this blog, we'll design a 1000 LPH RO plant for restaurants and discuss in detail the design basis process flow diagram and working function.

Design basis:

Determining the design basis is crucial before designing a RO plant. The design basis takes into consideration variables like the calibre of the feed water, the necessary output, and the kind of membrane to be used. In this particular case, we'll assume that the plant's input feed water should be free of iron and SDI 1, with a TDS of no more than 2000 ppm. Choose a different category of equipment that can manage higher TDS levels, such as 3000ppm, 4000ppm, 8000ppm, or even higher, if any of these criteria do not match your water's specifications. Water shouldn't contain any iron.

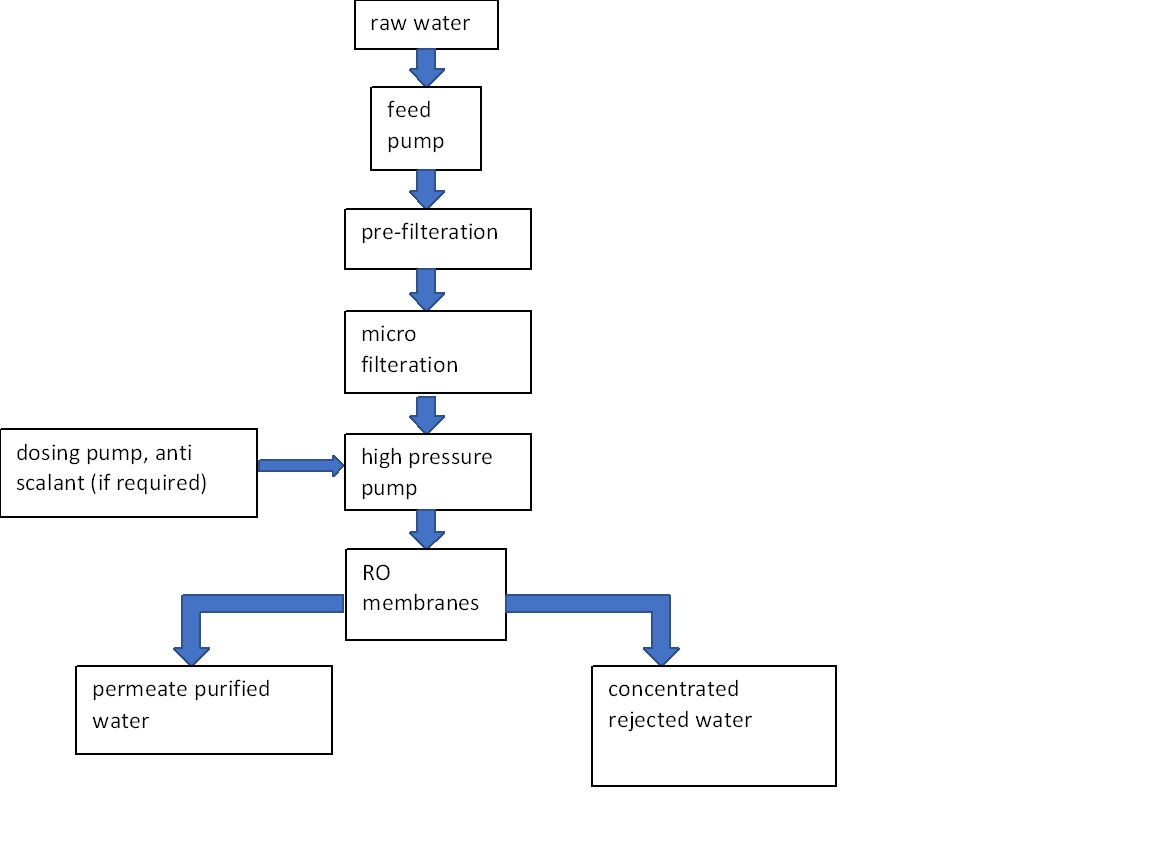

Process flow diagram:

1.Pre-Treatment: In order to prevent downstream equipment damage, suspended particles and other contaminants are removed from the feed water during pre-treatment. Processes including sedimentation, filtration, and disinfection may be used as part of the pre-treatment.

2. High-Pressure Pump: To push the pre-treated water through the RO membrane, a high-pressure pump is used to pump the water to a high pressure.

3. Micro filtration: To eliminate suspended debris and prevent the introduction of foreign material into the final treatment, a cartridge filter is offered.

4. Reverse osmosis membrane (RO): The RO membrane purges the water of dissolved salts, minerals, and other contaminants.

5. Permeate Tank: To be used for distribution or further treatment, the purified water or permeate is gathered in a permeate tank.

6. Concentrate Stream: The concentrate or reject stream, which contains the contaminants the RO membrane eliminated, is sent to be treated further or discarded.

7. Post-Treatment: To achieve the appropriate water quality criteria, the permeate may go through post-treatment procedures such remineralization, disinfection, and dechlorination.

Working function:

A motor pump (typically referred to as a feed pump) is installed in the pipe line of any raw water outlet or to the raw water tank outlet, and the water is then pushed to a prefiltration system that filters out sediment impurities up to 100 microns, followed by a sediment, micron filtration system, before being highly pressurized by a high pressure vertical multistage pump and fed to the RO Module (Reverse Osmosis membranes), where they perform their work.

The post-treatment system receives the purified water from the purified water tank and subjected it to UV sterilization and mineralization.

The purified water tank stores the mineralized water, which is then sent to the restaurants for consumption.

Conclusion:

In conclusion, it is important to carefully evaluate the feed water quality, product water requirements, and recovery rate while designing a 1000LPH RO plant for the restaurants. The RO plant's operation and process flow diagram are crucial for knowing the various processes in the RO process and how each component contributes to the creation of high-quality product water. In order to ensure that the water used in the production process is free from pollutants and impurities, the RO plant is a crucial piece of water treatment equipment for the restaurants.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us now your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-965-060-8473

Or write us at enquiry@netsolwater.com