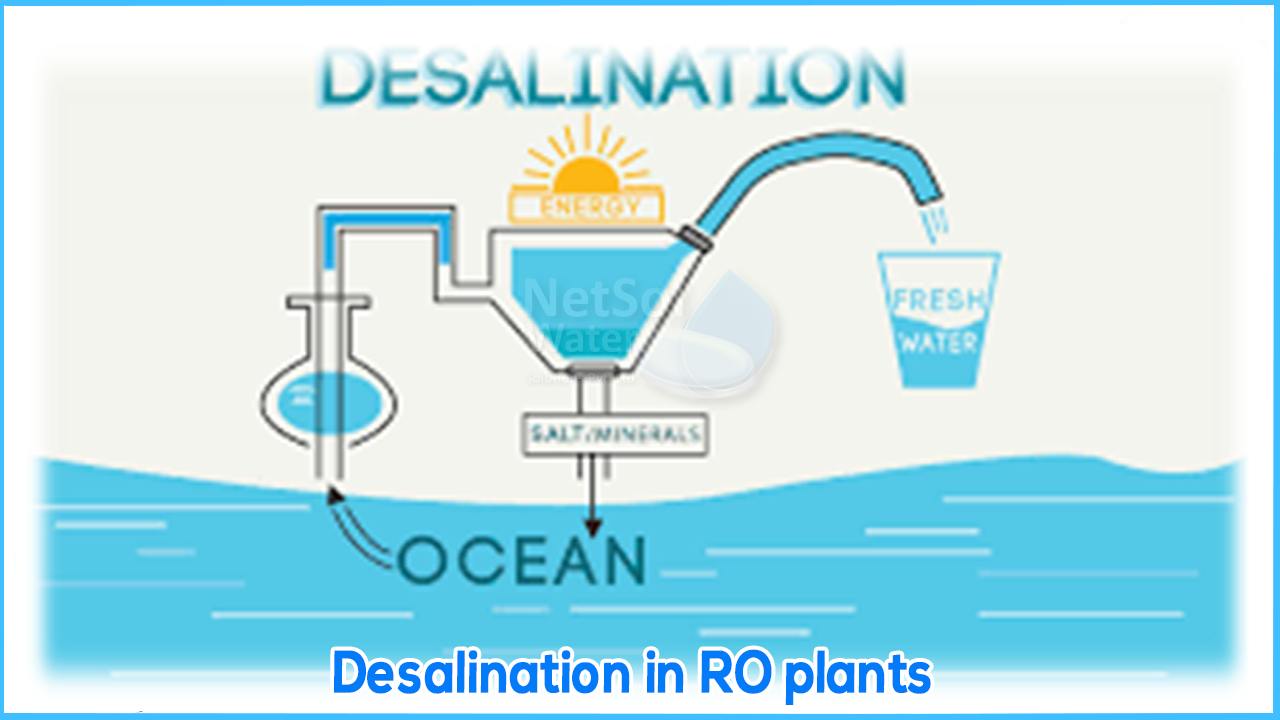

Desalination in RO plants

Desalination innovation has brought freshwater, modernization, and business development to parts of the world that would otherwise have remained inaccessible. Due to a lack of regular wellsprings of new water, numerous nations, regions, outfitted administrations, and ships want to create new water through desalination. This innovation has not only accelerated progress, but it has also improved the health and government assistance of many people. Refining type desalination frameworks consume more energy to deliver new water and, as a result, minimal expense energy available is refining financially.

The reverse osmosis (RO) process was developed to desalt saline water supplies. This cycle is dependent on the head of assimilation and necessitates the use of a layer boundary to separate salts from water. Because switch assimilation innovation required significantly less energy to operate than refining, it was regarded as the breakthrough that would make desalination significantly more feasible in the world's water-scarce regions.

RO for water sanitization is now widely used for drinking water applications as well as high-value modern cycle applications such as electronic part assembly, drugs, synthetic compounds, kettle feedwater, clinical applications, and modern and city wastewater recuperation frameworks. Today, with a thorough understanding of feedwater source conditions, pre-treatment requirements, and excellent framework design, RO Plant can be applied to virtually any ground or surface water desalination/refinement application. RO has become the primary cycle in the overall water desalination market due to advancements in film assembly and application design.

COMPONENTS FOR MEMBRANE SOLUTIONS

- 1. Oversight of establishment and appointing

- 2. Supply of turnkey administrations

- 3. Support program

- 4. Management of O&M contract

- 5. Boron evacuation framework

- 6. Post-treatment and cleaning

HIGHEST LEVEL OF EXPERTISE FOR DESALINATION

- 1. Modified Pre-treatment Frameworks: Ensure maximum efficiency and life expectancy of Reverse Osmosis plants.

- 2. Advanced Pressure Centre Design: Increasing film throughput and salt dismissal by utilising extremely capable high-pressure syphons and interaction configuration.

- 3. Energy Recovery System (ERS): Enables IDE plants to offer the lowest desalination energy utilisation in the industry.

- 4. The most advanced layers: Increasing proficiency while limiting speculation.

- 5. Adaptable financing packages: Assisting clients in transforming driven dreams into reality, all within accelerated cut-off times and severe monetary structures.