Petroleum refinery effluents (PRE) are wastes generated by the crude oil and fuel processing sectors, as well as the petrochemical intermediate products industry. These effluents are a major source of contamination in the natural ecosystem. In addition to the industrial toxins, the effluents contain oil and grease.

Let’s understand CPCB guidelines for petroleum oil refinery industry effluent treatment plants.

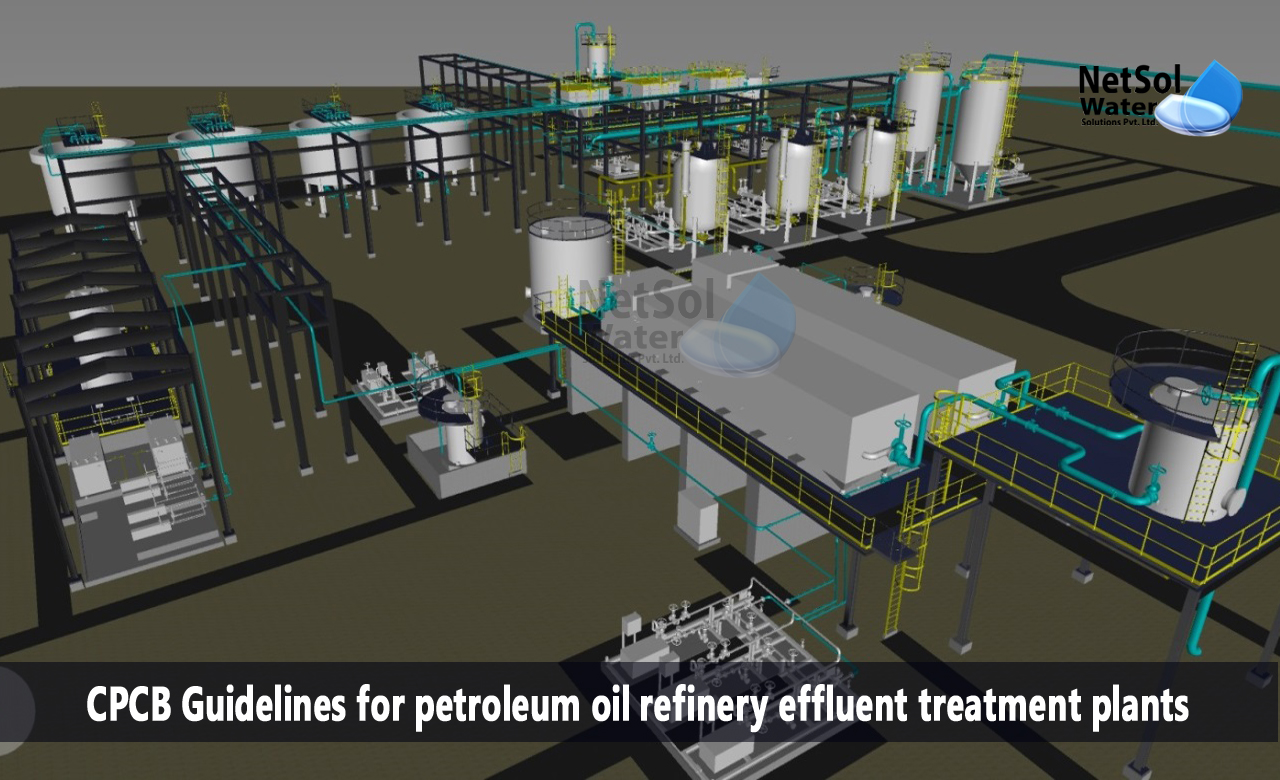

CPCB Guidelines for petroleum oil refinery ETP Plants

· pH: 6.0-8.5

· Oil & Grease: 5.0 mg/l

· BOD 3 days, 27oC: 15.0 mg/l

· COD: 125.0 mg/l

· Suspended Solids: 20.0 mg/l

· Phenols: 0.35 mg/l

· Sulphides: 0.5 mg/l

· CN: 0.20 mg/l

· Ammonia as N: 15.0 mg/l

· TKN: 40.0 mg/l

· P: 3.0 mg/l

· Cr (Hexavalent): 0.1 mg/l

· Cr (Total): 2.0 mg/l

· Pb: 0.1 mg/l

· Hg: 0.01 mg/l

· Zn: 5.0 mg/l

· Ni: 1.0 mg/l

· Cu: 1.0 mg/l

· V: 0.2 mg/l

· Benzene: 0.1 mg/l

· Pyrene: 0.2 mg/l

Notes:-

(i) Concentration limitations must be met when releasing effluent, excluding discharge from sea water cooling systems, to the receiving environment (surface water bodies, marine systems or public sewers).

If treated effluent is used directly for irrigation/horticulture purposes (inside or beyond the refinery's premises), make-up water for cooling systems, fire fighting, etc., the concentration limitations must be met at the exit before the effluent is taken for such use. However, for the purposes of compliance, any use in the process, such as the use of sour water in the desalter, is prohibited.

(ii) In the event of circulating saltwater cooling, the blow-down from cooling systems must be monitored for pH and oil & grease, as well as hexavalent & total chromium, if cooling water is chromate treated, and must adhere to the concentration limitations for these parameters.

If treated effluent is reused as cooling water make-up, all parameters (as applicable for treated effluent), must be monitored and meet the stipulated standards.

(iii) In the event of once-through cooling with saltwater, the oil and grease concentration in the cooling water effluent shall not exceed 1.0 mg/l.

Conclusion

The wastewater created by the refineries includes high toxins. Thus, effluent treatment in petroleum oil-refineries is a multi-stage procedure that purifies wastewater, before it enters a natural body of water, is applied to land, or is reused. Because, each receiving body of water can only accept a specific amount of contaminants before degrading, the goal is to decrease or remove organic matter, sediments, minerals, and other pollutants.

As a result, each effluent treatment plant must conform to discharge criteria, which are often established by the relevant environmental authority as permitted levels of pollutants, commonly stated as BOD-5, COD, suspended solids (SS), total dissolved solids (TDS), and others.

Manufacturer of ETPs for petroleum oil refineries

Netsol Water provides a wide range of modern treatment solutions, for effluent treatment in the oil refineries, including water softener, membrane technologies, RO Plants, etc.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.