What are Conventional Activated Sludge systems?

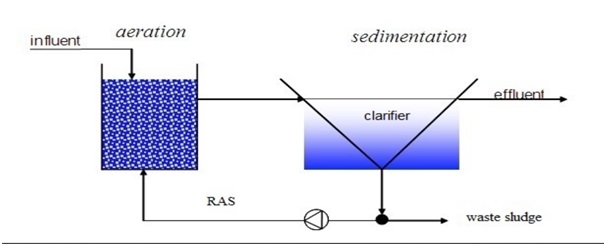

An aeration tank is utilized for biological degradation, and a secondary clarifier (sedimentation tank) separates the sludge from the treated wastewater in a conventional activated sludge (CAS) system.

The aeration tank is the initial phase in a CAS system, where wastewater is combined with air to activate microorganisms. When organisms collide while digesting wastewater, bigger particles called flocs emerge, which have a greater potential to destroy the biological components of the wastewater.

A secondary clarifier or settling tank follows the aeration basin. Microorganisms with adsorbed organic material sink during this stage. The clarifier's water is transferred to disinfection and final discharge facilities, or to other tertiary treatment facilities for additional purification.

The surplus microorganisms may simply be sent to any of sludge treatment options, where energy can be extracted from the biosolids. This final stage completes the wastewater treatment plant's energy cycle, allowing it to operate without the need of fossil fuels. Another portion of the microorganisms is returned to the aeration tank to maintain a sufficient load of microorganisms for the biological degradation processes to continue.

Advantages of Conventional Activated Sludge (CAS) Systems

- Low installation cost. Thus, it is Cost effective

- Good quality effluent

- Small land area requirement

- Loss of head is small

- Freedom from fly and odour nuisance with high degree of treatment

- Easily maintained mechanical work

- Self-sustaining system

Modification of Activated Sludge Systems

Th?ere are several changes to the activated sludge process.

Each change is intended to solve a specific circumstance or issue. Differences in mixing and flow patterns in the aeration basin, as well as the methods in which the microorganisms are combined with the entering wastewater, characterise such variations.

The major process modifications of the activated sludge process are:

1: Tapered aeration

2: Complete mix

3: Step aeration

4: Contact stabilization

5: Extended aeration

6: Pure oxygen systems

A: Tapered Aeration

The traditional activated sludge technique is comparable to the tapered aeration systems. The placement of the diffusers is the most significant distinction. At the influent end, where more oxygen is required, the diffusers are close together. The diffuser spacing is increased as you get closer to the opposite end of the aeration basin.

B: Step Aeration

The returning sludge is applied at many locations in the aeration basin during step aeration. Sludge is applied in different channels or stages, and the tank is separated into three or more parallel channels with around-the-end baffles. The oxygen requirement is divided evenly.

C: Complete Mix Aeration

The influent and returned sludge are combined and applied at various places throughout the length and width of the basin in full mix aeration. Mixed liquor suspended solids (MLSS) flows through the tank to the effluent channel after the contents are mixed. The oxygen requirement and organic loading remain consistent throughout the basin's length.

D: Contact Stabilization

Primary therapy is not necessary in contact stabilization. In the contact tank, activated sludge is combined with influent, and the organics are absorbed by microorganisms. The MLSS has found a home in the clarifier. The organics in the returning sludge are stabilized by aeration in the reaeration basin.

The process uses half as much tank space and may be constructed as a package plant for flows ranging from 0.05 to 1.0 MGD. On the downside, this system is more difficult to regulate due to the failure of many typical control computations.

E: Activated Sludge with Extended Aeration

Primary treatment is not required for extended aeration. It makes use of a big aeration basin to sustain a high population of microorganisms. It's for minor flows from neighbourhoods, schools, and other places. This method is often used in prefabricated packaging plants. It has a canal in the shape of a racing track, with rotors that deliver oxygen and keep circulation going. The procedure usually results in high-quality effluent and little activated sludge.

F: Systems for Pure Oxygen

Oxygen is distributed into aeration tanks that are covered. To lower carbon dioxide levels, a portion of the gas in the tank is squandered. The method is appropriate for high-strength wastes where room is restricted. The production of oxygen necessitates the use of specialized equipment.

Feel free to contact Netsol Water with any queries you may have about custom-designing and manufacturing of biological wastewater treatment systems. Contact us on +919650608473