The concentrated brine from the primary reverse osmosis plant or RO Plant drains as the wastewater. If concentrated water from the RO process is discharged directly into the soil, surface water, or ocean, it may contaminate those areas. If concentrated water from the RO process is discharged into a municipal wastewater treatment system, the excessive total dissolved solids have a negative impact on the development of activated sludge.

When released into the environment, the highly concentrated RO water as well as the chemicals added by the cleaning agent and scale inhibitors, are certain to have negative consequences. Thus, finding an affordable RO concentrated water treatment solution is crucial to safeguarding the environment and water resources. Therefore, in this blog we will go over the various concentrated water treatment solutions in RO Plants.

Use of RO Plants and its advantages

Reverse osmosis membrane separation technology has been used extensively in many industries recently, because it has the benefits of no material phase change, low relative energy consumption, good desalination effect, mature and reliable treatment process, simple equipment, high levels of automation, easy operation, and management, etc.

Production of concentrated water from RO Plants

Reverse osmosis technique now has a design yield of roughly 75%, but the actual yield is significantly lower, producing only about 30% of concentrated brine.

The amount of concentrated water produced will be significantly higher, maybe reaching 50%, if the raw water is very low-quality brackish groundwater or seawater or wastewater.

Currently, a lot of reverse osmosis operations result in concentrated water that is discharged straight without treatment, wasting water and energy and polluting the environment.

Importance of treating reverse osmosis plants’ concentrated water

Treating concentrates on three goals for reverse osmosis concentrated water:

1: Optimise the reverse osmosis process' design to cut down on the volume of concentrated water;

2: Explore cost-effective and efficient treatment options to lessen the impact that comes, from the direct release of reverse osmosis concentrated water into the environment.

3: Considering that the environment may be harmed by the direct discharge of reverse osmosis concentrated water, certain investigations on efficient treatment methods are required to lessen the harm;

What are the Concentrated water treatment options in RO Plants?

High calcium and magnesium content as well as high hardness are the main issues with reverse osmosis concentrated water. Generally speaking, it can reach the standard discharge after a straightforward water softening treatment.

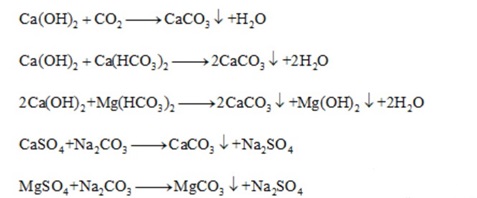

In order to soften concentrated water and lessen its negative environmental effects, softening processes typically involves adding alkaline materials like lime and soda ash. These substances react with the calcium and magnesium in concentrated water, to produce carbonate precipitate, which is then removed from the water body.

The following is the chemical reaction:

Return of concentrated water from RO Plants

Reverse osmosis plants create concentrated water, which is returned in part to the high-pressure pump's front end where it is mixed with feed water, before being processed once more in the membrane module.

Reverse osmosis equipment recovery rates can be increased by doing this. In systems with limited water production, when the water flow cannot travel through the 12 m long membrane module, it is very useful.

However, the risk of reverse osmosis plant scaling grows as the concentration of pollutants in the feed water rises, as a result of the return flow of concentrated water. Thus, the operational control and management of the RO Plant must be improved.

Reusing Commercial RO concentrated water after treatment

According to reverse osmosis theory, even if a RO Plant is properly built to maximise recovery rates, the volume of concentrated water that is produced by the system must make up at least about 25% of the total volume of incoming water.

The amount of concentrated water produced every hour for major water consumers in businesses like the steel and chemical industries, can amount to hundreds of tonnes. It would waste a lot of water and energy if it were released as wastewater.

Therefore, finding a viable method of reusing concentrated water, and achieving partial replacement of new water by wastewater, is of enormous practical value and has extensive environmental benefits.

If you want to get high-quality RO plants, call Netsol Water right away!

Netsol Water is a corporation based in Greater Noida, India. Our skilled technicians can perform services, maintenance, and replacements on-site, and can offer all the necessary technical assistance to produce the finest outcomes.

We have been offering India's top Commercial RO Plants for over a decade. Thus, we are delighted to offer you field services as well as assistance with your choice of treatment products, in addition to providing comprehensive system design and engineering. To find out more, get in touch with us at +91 9650608473 or enquiry@netsolwater.com