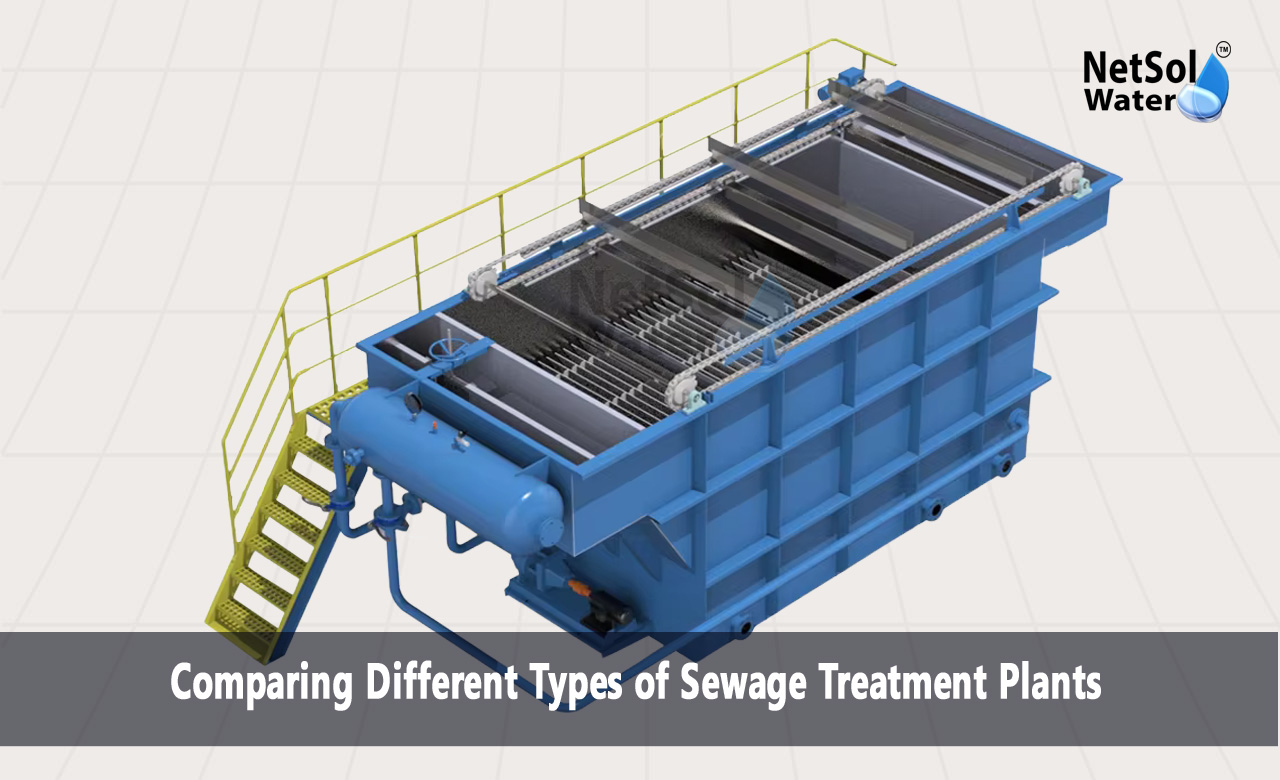

Comparing Different Types of Sewage Treatment Plants

Raw sewage poses serious health risks to communities. Yet many people don't know how treatment plants turn hazardous waste into safe water. This blog explores the various types of sewage treatment plants that protect public health and the environment.

Modern sewage treatment involves multiple steps to clean wastewater before releasing it back into nature. Each type of treatment plant uses different methods but shares the same goal - to remove contaminants and produce water that meets environmental standards. Treatment plants also help recover resources like biogas and fertilizers from waste.

The choice of treatment plant depends on factors like population size budget space requirements and local regulations. Small towns need different solutions than big cities. Industrial areas have different needs than residential zones. Understanding these differences helps communities pick the right type of plant.

We will compares the main types of sewage treatment plants. We'll explore how each system works its benefits drawbacks and ideal uses. Whether you manage a facility or want to learn about wastewater treatment this guide will help you understand your options.

Treatment Methods:

Treatment methods form the core of any sewage treatment plant. They determine how effectively plants remove pollutants and protect public health. The right treatment method ensures clean water output while keeping operating costs manageable. These methods also impact how much energy plants use and their effect on the environment.Let us look at the main treatment methods used in modern plants:

Activated Sludge Process

The activated sludge process stands as the most common treatment method worldwide. This biological treatment creates an environment where helpful bacteria thrive. These microscopic cleaners break down harmful substances in wastewater.

The water flows through large tanks where air bubbles mix with the waste. This mixing helps bacteria grow and consume pollutants. The bacteria cluster together forming activated sludge. Clean water separates from this sludge and moves to the next stage. Some sludge returns to the tanks to keep the bacterial population strong.

Trickling Filters

Trickling filters offer a different approach to biological treatment. These systems use beds of material where helpful bacteria grow. The beds consist of rocks plastic pieces or specialized filter media. Wastewater sprays over these beds and slowly drips down.

As water moves through the filter bacteria clean it naturally. Air flows between the filter pieces providing oxygen to the bacteria. This passive aeration saves energy compared to other methods. The cleaned water collects at the bottom and moves to final treatment.

Membrane Bioreactors

Membrane bioreactors combine biological treatment with advanced filtration. These systems use special membranes to separate clean water from waste. The membranes act like very fine sieves catching even tiny particles.

This method produces exceptionally clean water. It works well in places with strict environmental rules. The system needs less space than traditional methods. However it costs more to build and operate than simpler systems.

Technology Levels:

The technology level of a treatment plant must match local capabilities. Advanced technology can improve performance but also increases complexity. Plants need the right balance of sophistication and practicality. This balance ensures consistent operation and sustainable costs.Let us examine the main technology levels available:

Basic Technology Plants

Basic technology plants use simple proven methods. These plants focus on essential treatment steps without fancy features. They suit areas with limited resources or technical expertise.

The equipment includes basic pumps simple controls and minimal automation. Operators can learn to run these plants quickly. Maintenance needs stay manageable with standard tools and skills. These plants cost less to build but may need more manual work.

Intermediate Technology Plants

Intermediate plants add more sophisticated equipment to basic designs. They automate some processes while keeping others manual. This mix provides better control without excessive complexity.

These plants use computer controls to monitor treatment. They include backup systems for important equipment. Operators need more training but the work remains straightforward. The plants balance performance with operating costs.

Advanced Technology Plants

Advanced plants use cutting-edge equipment and controls. They automate most processes and collect detailed data. These systems suit large cities or industrial areas with skilled staff. The plants include advanced sensors automated controls and complex treatment methods. They can handle varying waste loads and strict quality standards. However they need skilled operators and careful maintenance.

Scale Considerations:

The size of a treatment plant shapes its entire design. Different scales need different approaches to work efficiently. Plant scale affects everything from treatment methods to staffing needs.Let us explore how scale influences treatment plant design:

Community-Scale Plants

Community plants serve small towns or neighbourhoods. These plants process waste from a few thousand people. They focus on simple operation and consistent performance.

The design keeps everything compact and accessible. Operators can manage most tasks alone. The systems use proven methods that work reliably. These plants often choose natural treatment methods to save costs.

Municipal Plants

Municipal plants handle waste from medium-sized cities. They process more waste and need more sophisticated systems. These plants balance complexity with practical operation.The facilities include multiple treatment lines for flexibility. They employ full-time operators and maintenance staff. The systems monitor water quality carefully. These plants often use activated sludge or similar proven methods.

Metropolitan Plants

Metropolitan plants serve large urban areas. They process huge amounts of waste continuously. These plants need complex systems and careful management.The facilities use advanced treatment methods and automation. They employ many skilled workers across multiple shifts. The systems include extensive monitoring and control equipment. These plants often add special treatment steps for industrial waste.

Conclusion:

Understanding different types of sewage treatment plants helps you make better choices. Each type offers unique benefits for specific situations. Contact wastewater treatment experts to find the right solution for your needs. They can help you evaluate options and plan your project successfully.

To explore customised commercial RO plants, Industrial RO plants, ETP or STP solutions for your needs in your areas and nearby regions, Contact Netsol Water at:

Phone: +91-965-060-8473, Email: enquiry@netsolwater.com