Commercial RO Plant: Design

Let’s Review it!

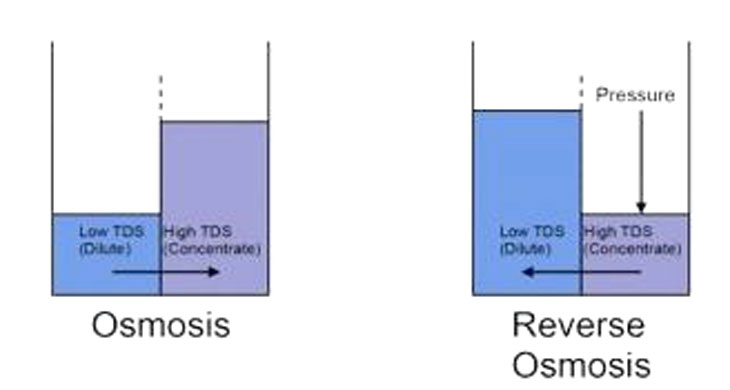

RO is now employed in a wide range of applications; from small under-the-sink drinking water systems to huge municipal drinking water systems because it removes both dissolved ionic and organic pollutants. To optimize performance and membrane life, the system design of RO systems should be studied.

RO Design

Membranes with diameters of 2.5" and 4" are used in small commercial systems. The membranes are commonly contained in single membrane housings made of polyvinyl chloride (PVC) or stainless steel and placed vertically. Although some PVC or stainless-steel piping may be present, hoses are most commonly used to link the RO housings. This cuts down on material costs and assembly time. The instrumentation in commercial systems is rather simple. There are normally permeated and concentrate flow rotameters with a concentrate pressure gauge and a motor starter, depending on the manufacturer.

The RO system is usually started and stopped using a preprogrammed microcontroller based on the product level in the permeate storage tank. The microprocessors also include a feature called "pretreatment lockout," which prevents the RO Plants from starting while a media filter or softener is in backwash or regeneration.

A multimedia filter, softener, and activated carbon filter should all be included in the pretreatment of commercial systems. Fiberglass reinforced plastic (FRP) filter and softener vessels with a timer-based control valve are back washable. A "Big Blue" style plastic housing with a five-micron pre-filter and a 304 stainless steel multistage pump should be included in the RO system.

Concentrate flow is controlled by a stainless-steel needle valve, while permeate flow varies. Some parts may be brass rather than stainless steel, depending on the manufacturer. This idea is focused on price competition and the low cost of RO membranes.

The pricing determines the commercial system design. Concentrate recirculation, pre-filter inlet and outlet pressure gauges, pump throttling valve, soft motor starter or variable frequency drive, FRP vessels, so-called "cold water" membranes, and permeate pressure gauges can all be incorporated if the buyer is informed on the benefits.

Rather than being based on the application and membrane flux, the commercial RO plant permeate flow rating is frequently close to the maximum authorized by the RO membrane manufacturer. Without concentrate recirculation, recoveries range from 20% to 50%, whereas with concentrate recirculation, recoveries can reach up to 75%.

Because the feed water flow rate decreases as permeate goes through the membrane, it becomes more concentrated, resulting in significant scaling and fouling containments as it travels further over the membrane surface.

A minimal flow is essential to maintain high velocity and turbulence on the membrane surface in order to reduce fouling or scaling of the concentrate containments. By mixing feed water with rejected concentrate water, the concentrate recirculation option allows for larger recoveries and reduced wastewater.

Netsol Water incorporates the latest technology that conforms to the predefined industrial standards and quality. Therefore you don’t have to worry about the quality and services. We are one of the most cost-effective companies in commercial RO plant manufacturing.

Contact us to discuss your requirements. We can be reached at 9650608473 and 9650795306, or feel free to leave your query at enquiry@netsolwater.com.