What is an Oil Water separator?

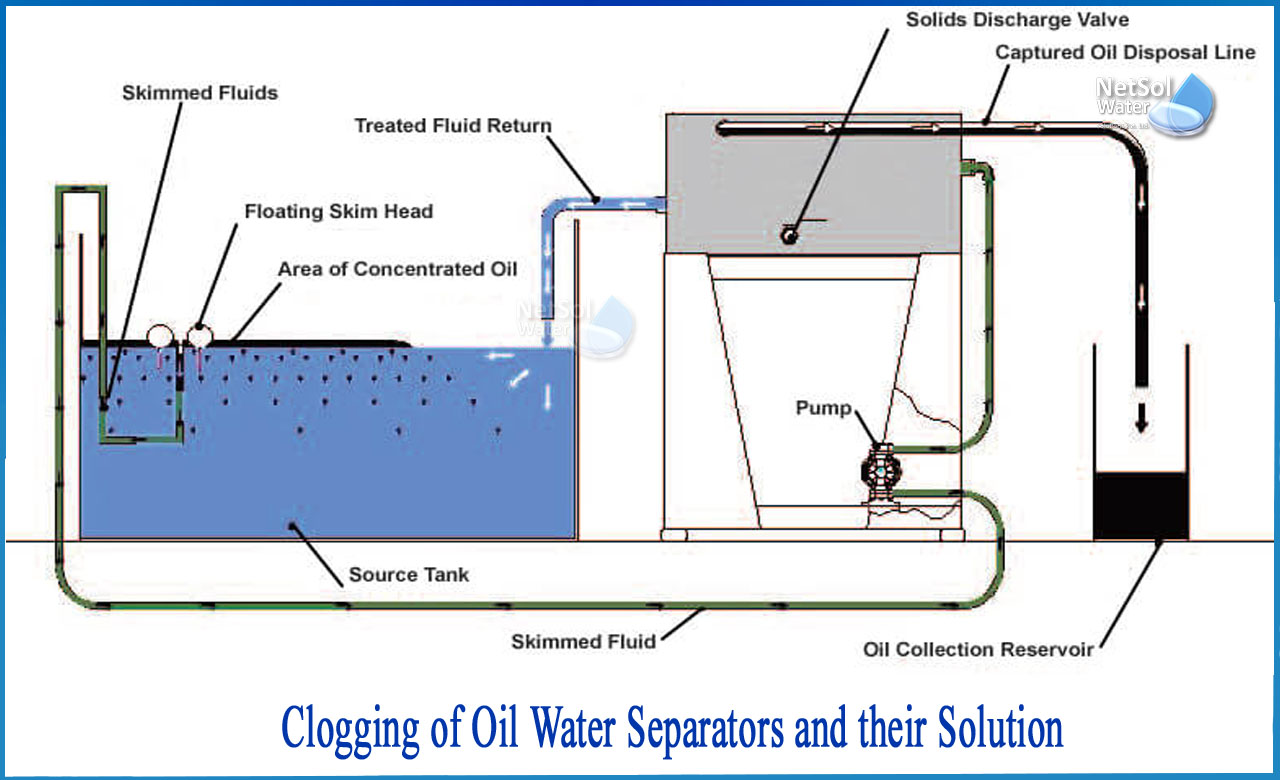

Oil water separators are critical elements of industrial wastewater management equipment. They assist businesses in complying with regulatory requirements and protecting the environment from pollution. They must, however, be cared for, just like any other piece of machinery, to guarantee that they function as intended.

Problems with Oil-water Separators

The worst-case scenario is that you discover anything is wrong with your oil water separator after your plant releases water that is out of specification. To avoid this, here are some things you should check on a regular basis to guarantee your oil water separator continues to work properly without encountering problems like clogging:

A: The water is not flowing or the flow into the oil water separator is low

Low water flow might be a sign of a problem with the pump, sump level, or suction line. Some of these difficulties are universal to all separators.

To clear the suction line of a gravity or coalescing separator, follow these steps:

-Flushing is a good way to get rid of clogs.

-Repair any cracks or loose fittings in the system that enable air to enter.

-Remove any impediments from the foot valve.

B: Water flows into the waste oil container, or water flows out of the separator's top

-It's possible that the waste oil collar within the unit is set too low. When the pump is working, the collar should be positioned five millimeters above the water level to prevent free water from being skimmed off with the waste oil.

-Look for a clog in the discharge line. Examine media packets and clean as needed. Regular blockages may necessitate additional inquiry into unit size and solid material clearance.

C: The waste oil container has no oil in it

It's possible that the waste collar within the unit is set too high. When the pump is working, the collar should be positioned five millimeters above the water level to ensure that oil is evacuated from the system and does not accumulate inside the separator.Because the waste water stream is free of oil, no oil is collected. There is no need to take any action.

D: The pump is overloading and the system is switching on/off

Electrical or control panel difficulties are frequently the source of problems with turning equipment on or off.

E: The water discharge does contain oil

There are three possible reasons for oil getting into the water discharge stream.

To begin with, an oil leak may have overburdened the system. Second, the waste oil decant tank might be completely full. Finally, inspect and clean media packs according to the operations and maintenance plan.

F: The oil water separator has a smell coming from it

-Check all fundamental operating conditions. If the issue persists, have the device serviced by technical specialists.

-In the wastewater stream, oils have created an emulsion that cannot be extracted by a coalescing or vertical gravity separator. Make sure there are no unauthorized degreasers or detergents in the system.

The problem of clogging is usually accompanied by_

1: A lot of downtime for cleaning and maintenance.

2: Both costly and time-consuming.

3: We'll have to make do with low flow and poor effluent quality.

4: We have to spend a lot of money on new media rather than dealing with all of the aggravating maintenance.

A More Effective Plate Separator Media!

Fortunately, Netsol Water offers a separator medium that eliminates these issues and can be retrofitted into many OWS/CPI Separator tanks with ease. For years, we have successfully used this method for oil water separation and solids removal. Due to the greater distance between separator plates, it not only offers excellent oil separation but also readily sheds particles.

If you need any specific advice on oil water separators as well as their maintenance and troubleshooting, our team of experts can help.