How to choose the best ETP Plant based on Cost and Area?

Every factory that is having an ETP developed and built must determine which components are required to treat the waste generated by that facility. The answers to the questions, such as the quality and amount of the wastewater to be treated, must be used to make this conclusion.

1: Based On Biological Treatment

Microorganisms that are suited to breakdown the components of the effluent to be treated are required in biological treatment plants. If at all practicable, new reactors (either activated sludge or fixed film systems) should be built with the activated sludge from an existing ETP, particularly the one that treats a similar waste stream.

Quality of output: Evidence suggests that, with the exception of colour, the output quality of biological treatment can meet national criteria for the majority of the needed parameters. A biological ETP that is appropriately built may effectively meet BOD, pH, TSS, oil, and grease criteria. However, as previously stated, the chemicals in industrial effluent may be harmful to microorganisms, necessitating pretreatment. Similarly, because most dyes are complex compounds that are difficult for bacteria to digest, very little colour is generally removed.

2: Physico-chemical Treatment:

Screening, an equalisation unit, a pH control unit, chemical storage tanks, a mixing unit, a flocculation unit, a settling unit, and a sludge dewatering unit are the fundamental equipment’s required for a stand-alone physico-chemical treatment plant.

Quality of the output: It is feasible to remove much, if not all, of the colour with the physico-chemical procedures. However, reducing BOD and COD to the levels required to fulfil the national effluent discharge standard is challenging, and removing TDS is impossible. The rate of removal is determined by the quality of the influent wastewater.

3: Physico-chemical and Biological Treatment:

A mix of physical operations, physico-chemical, and biological processes are utilized in this form of treatment. Screening, an equalisation unit, a pH control unit, chemical storage tanks, mixing units, flocculation units, a primary settling unit, an aeration unit, and a secondary settling unit are the fundamental equipment’s required for a physico-chemical and biological treatment plant. The biological unit is always placed before the physico-chemical unit.

Output quality: These are the most common type of ETP used for treatment of textile waste, and they are the most likely to meet the water quality standards, as they provide the benefit of physical, chemical, and biological treatment, increasing BOD and COD removal efficiency to 90%.

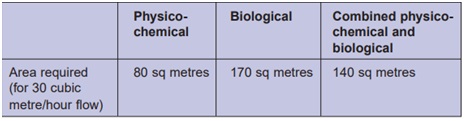

Comparison of the Area Requirements

The size of an ETP is mostly determined by the quality of the wastewater to be treated, the flow rate, the kind of biological treatment to be utilized, and the placement of various treatment units. In general, physicochemical treatment plants require the least amount of land, while biological treatment plants require the most.

However, good civil engineering can significantly reduce the amount of land required, and some factories in India have had ETPs designed on multiple levels to reduce the amount of land required. Because this will need additional pumps and pipes, as well as thicker tank walls, building costs for tall towers may be greater.

Area Requirements

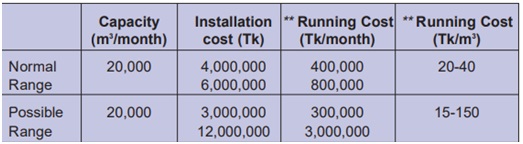

Cost Comparison

The cost of installing an ETP depends on a variety of factors, including the materials used, the quality and source of equipment (e.g. pumps and air blowers), the land area and dimensions for construction, the quality and quantity of wastewater to be treated, and the quality of the required output. Furthermore, the operational expenses of ETPs can vary significantly depending on the quality and quantity of inputs such as chemicals, the efficiency and size of motors, and therefore the energy required, the treatment process, and the efficiency of ETP management.

The table below illustrates the probable expenses. These figures are based on cost estimates supplied by industrialists who have or plan to install ETPs (and therefore may not be entirely accurate.)

Installation and Operational Costs Comparison

Technical assistance provided by Netsol_

Netsol Water collaborates with a wide range of international organizations to tackle complicated water and wastewater problems by strategically integrating modern treatment technology with practical solutions.

Think of us when it comes to wastewater management for your organization, adapted to your specific needs! We use a cost-effective method to reuse and recycle water, as well as deal with us for wastewater treatment equipment’s and develop your business while complying with Environmental standards.