What are the most prevalent disinfection methods for treated wastewater?

Traditionally, the most popular method of the wastewater disinfection was the use of chlorine gas. Chlorine gas is a reasonably affordable chemical, but it is a highly hazardous substance that must be handled and transported with considerable caution. It's kept under pressure in enormous tanks before being released as a gas into the effluent. A diluted liquid form of chlorine, sodium hypochlorite, is also widely utilized.

Advanced Technologies for wastewater disinfection

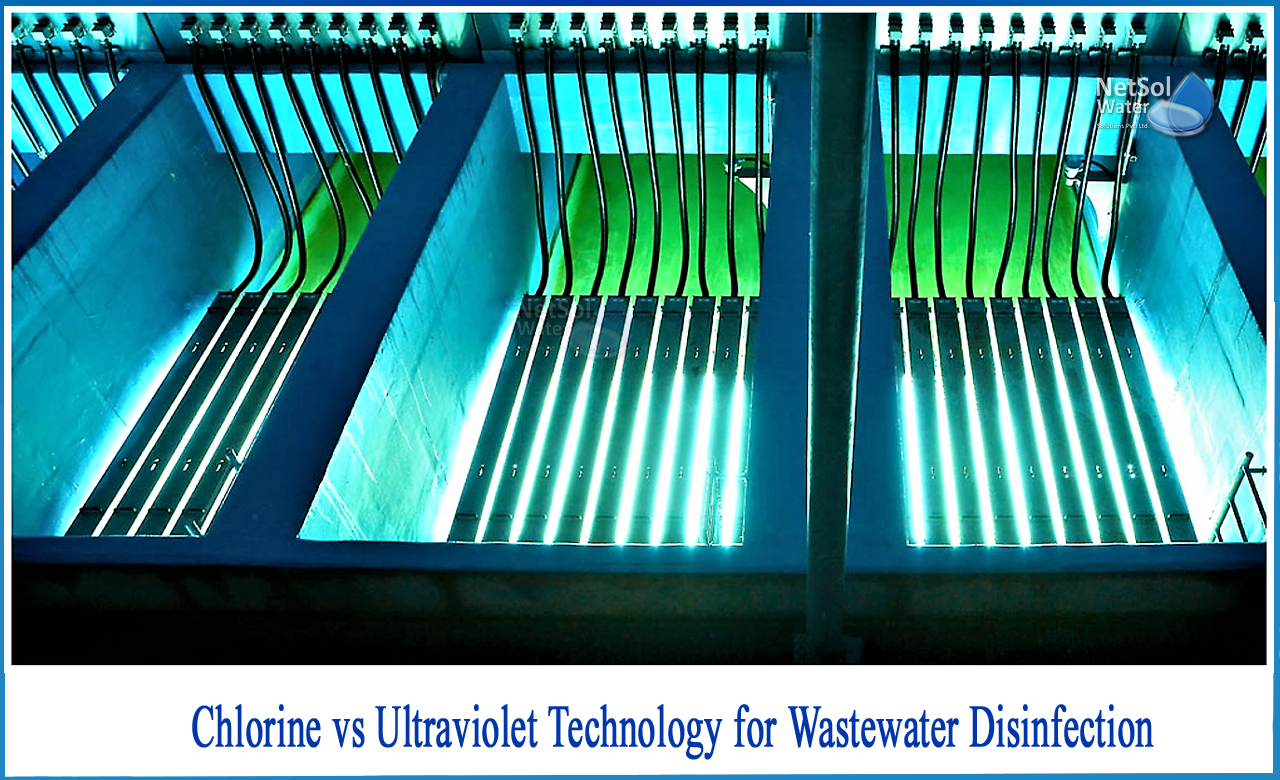

UV disinfection is now routinely used to disinfect municipal wastewater all over the world. Because UV disinfection is a safe and cost-effective alternative to chemical disinfection, its popularity is fast expanding. It also creates no disinfection byproducts or a chlorine residue, neither of which are environmentally damaging. This disinfection procedure adds nothing to the water except UV light; hence it has no effect on the water's chemical composition.

When compared to chemical disinfection treatments, how successful is UV at killing pathogens?

UV is a low-cost, high-reliable method of protecting the population from dangerous microorganisms such as protozoa, bacteria, and viruses.

Chemical disinfection using chlorine is also efficient against these diseases; however, organisms resistant to chlorine, such as Cryptosporidium and Giardia, can be treated with UV radiation. UV, unlike chemical techniques to water disinfection, uses a physical mechanism to inactivate germs quickly and effectively. The time it takes to disinfect a surface ranges from a few seconds to several (>30) minutes for chlorine disinfection. This eliminates the need for huge chlorine contact chambers, resulting in a smaller installation footprint and lower installation costs.

What are the risks of using UV disinfecti?on instead of chlorination in terms of public safety?

UV disinfection has the advantage of being a physical procedure that does not alter the quality of the water, but it also has the disadvantage of not leaving a residual for monitoring. Pathogens can sometimes repair and reverse the destructive effects of UV through a "repair mechanism," known as photoreactivation, or in the absence of light, known as "dark repair".

Although these are valid concerns, they can be addressed by working with a UV supplier who has the necessary sizing tools as well as experience with cutting-edge controls and monitoring.

Sufficient UV dose prevents photo reactivation

A sufficient UV dose can be given by correct size to prevent photo reactivation.Furthermore, the real-time UV dose for the system may be monitored and adjusted by including a robust and calibrated UV lamp intensity sensor for dose management, ensuring ongoing proper disinfection.

What is the difference between Chlorine and Ultraviolet technology?

Chlorination equipment is usually only a minor part of the total capital cost. Because chlorination necessitates a long retention time, unless one already exists, a large chlorine contact tank or channel is necessary. The overall capital cost increases as a result of the additional concrete, civil works, excavation, and building.

Because chlorine gas is so harmful, it may be necessary to install an emergency scrubber system and an enclosed facility to protect operators and the surrounding population from a dangerous chlorine gas leak.

The equipment and chlorine contact tank expenses for sodium hypochlorite (liquid chlorine) are comparable to those for chlorine gas. If the hypochlorite is supplied to the plant, however, there will be additional costs for constructing storage facilities for this caustic chemical.

Difference between UV Disinfection and Chlorine Disinfection

|

Treatment Methods |

Benefits |

Drawbacks |

Maintenance |

|

UV |

No chemicals are required, and no disinfection byproducts are produced Simple to set up Can be used to treat Cryptosporidium and Giardia Will not change the flavour or smell of your water |

Pre-treatment is required (e.g. pre-filtration for sediment and softeners in hard-water areas) Some viruses necessitate a high level of UV exposure |

Lamp replacements on a yearly basis Quartz sleeve cleaning or replacement on a regular basis |

|

Chlorine |

It helps to get rid of some unpleasant odours and tastes Provides long-term disinfection Can aid in the removal of iron and manganese from water |

Requires the storage and usage of hazardous chemicals Chlorine levels must be monitored on a regular basis Cryptosporidium has a high level of resistance Frequently necessitates the use of a contact tank Professional installation is required Has the ability to change the taste and odour of water Corrosive Produces potentially hazardous by-products |

Looking for pieces that are loose, worn, missing, or broken Cleaning the entire system twice a year Clean any surfaces that are corroded Replenishment of chlorine supply Any clogged injection sites should be cleaned. |

If you want to know more about UV and Chlorine disinfection technologies, then you can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water Treatment Plants and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.