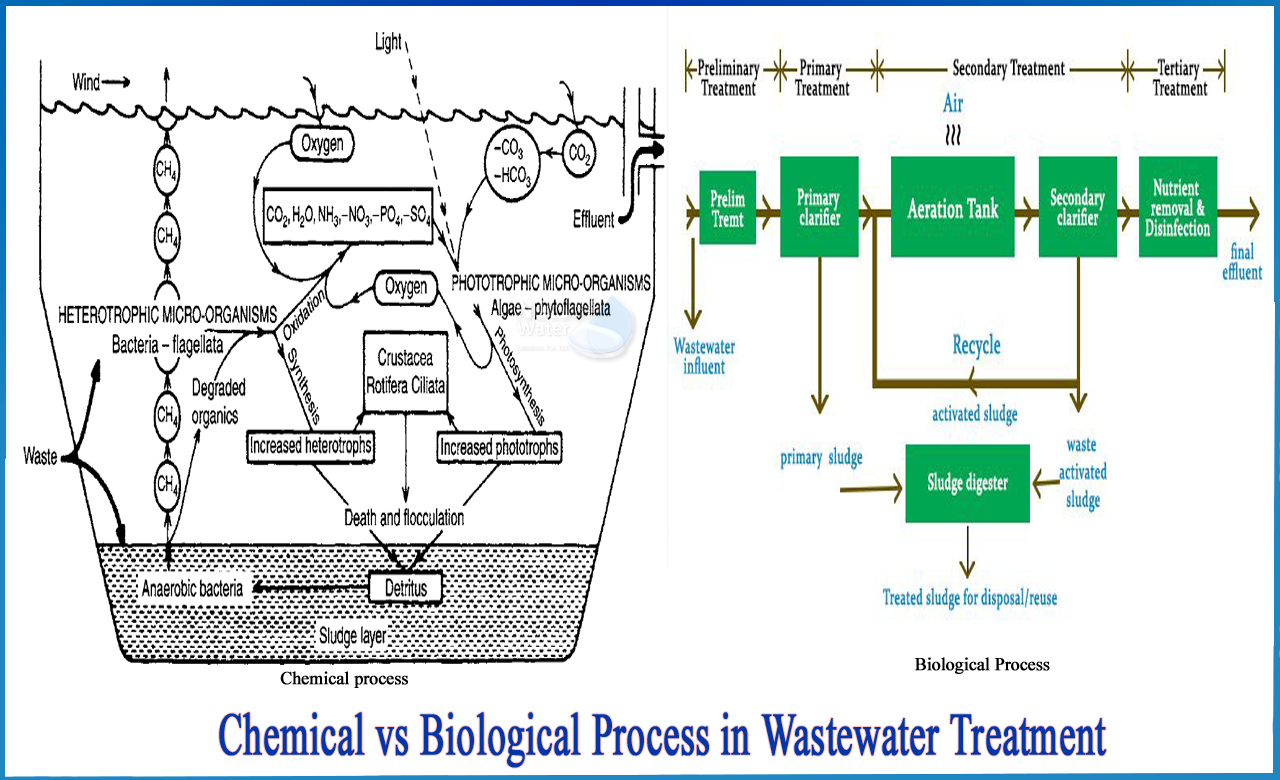

One of the first decisions you'll make when creating a treatment strategy for your industrial wastewater is whether to use chemical or biological treatment.

These two procedures treat wastewater streams containing a variety of impurities using quite different techniques. Chemical vs. biological wastewater treatment technologies are discussed further below to help you make an informed selection.

What are the difference between Chemical and biological process?

The technologies that are used are mostly determined by the pollutants that must be eliminated. As previously said, each of these methods is only effective at removing certain contaminants, so you'll almost always be forced to use one or the other.

Although treatment methods vary, the basic process for biological wastewater treatment includes the following steps:

-Pre-treatment: To remove particles or insoluble solids.

-Biological treatment: To remove particles or insoluble solids, Moving bed bioreactors, fixed bed bioreactors, membrane bioreactors, biological trickling filters, rotating biological contactors, sequencing batch contactors, and other technologies are used in biological wastewater treatment. In the biological realm, you can use the entire microbial kingdom to achieve your treatment goals.

-Post-treatment: To clear bacterial particulates and cleanse the water further.

Chemical wastewater treatment standard techniques, on the other hand, often include:

-Metal precipitation: It is a term used to describe the process of metals accumulating in coagulation and flocculation. After all the larger particles have settled out, various chemicals are applied to a reaction tank to remove the bulk suspended solids and other pollutants. This procedure removes all of the water's finer particles by mixing them into larger particles that settle away. Aluminium-based coagulates, such as alum and poly aluminium chloride, are the most extensively employed. A modest pH change may also aid in the coagulation of the particles.

-Ion exchange: which is commonly used in drinking water and other applications requiring high-quality water (like recycling the water for use in other processes or making steam)

-Disinfection: It uses chemicals like chlorine to kill any microorganisms that may be present in the wastewater before it is discharged.

What are the cost, footprint, and energy usage differences?

Chemical treatment relies on having the proper amount of reactant to achieve the desired reactions, and you normally pay for each kilogramme of chemical reactant you require. Bacteria, on the other hand, multiply on their own, so once you get them started and they're multiplying in the perfect growth environment, they'll work a little harder for you as long as they're happy. With this in mind, it's easy to see why using microorganisms is usually more cost-effective on a day-to-day basis.

The cost of building the biological system, on the other hand, may be higher up front. For your chemical reactants, you'll still need tanks, mixers, and pumps, but they're usually less expensive than a biological system with aeration, pH control, temperature control, and possibly some packing material. As a result, while biological wastewater treatment systems have a higher initial capital cost, they often have a lower operational cost than chemical wastewater treatment.

Electrical costs are typically the greatest contributing factor in the running costs of biological systems. In chemical treatment, on the other hand, your chemicals are always the most expensive part of the operation.

Keeping in mind that operating a chemical plant vs. a biological one often necessitates more labour. The features, flow rates, and goal effluent limits you're seeking to attain with the water will all influence the design of any treatment system. Furthermore, a biological treatment system may require a bigger footprint than a chemical treatment system to remove the majority of the contaminant.

Processes, be chemical or biological, it is essential to treat waste water before disposing it off which requires a professional help from water treatment companies like Netsol Water.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.