Overview

In many wastewater treatment facilities, foaming in the activated sludge process is a typical operational issue.

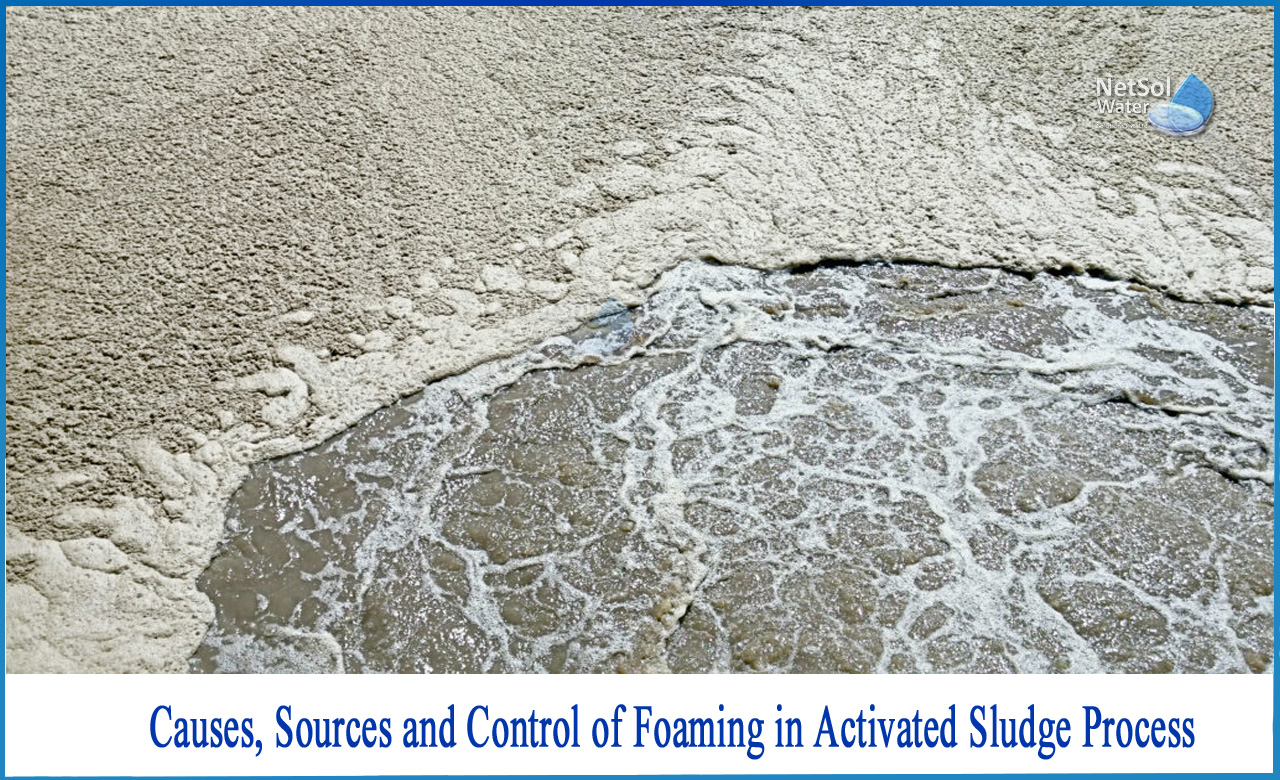

Foam can form in the aeration tank, the secondary clarifier, and the anaerobic digester. Typically, WWTP foam is sticky, viscous, and dark in colour. It floats and gathers on top of the tanks, taking up a significant portion of the solids inventory and reactor volume, reducing effluent quality and sludge retention time management (SRT). The foam can also overflow onto sidewalks and other nearby places, posing both operational and environmental risks.

What is the Causes, Sources and Control of Foaming in ASP?

Foaming can occur for a variety of reasons, including the presence of slowly biodegradable surfactants (e.g., household detergents) in industrial or municipal wastewater, excessive production of extracellular polymeric substance (EPS) by activated sludge microorganisms under nutrient-limited conditions, proliferation of filamentous organisms, and gas supplied in aeration tanks or produced in the anoxic zone of aeration tanks, secondary clarifiers, and anaerobic systems.

In a WWTP, stable foaming is the result of interactions between gas bubbles, surfactants, and hydrophobic particles. At the air-water contact, the hydrophobic particles aggregate and strengthen the water film between air bubbles. Meanwhile, the particles operate as a surfactant collector, which helps to keep the foam stable. Aeration, mechanical mixing, and biological processes such as denitrification and anaerobic digestion generate gas bubbles in WWTPs.

Sources of foaming in Activated Sludge Processes

The filaments “Nocardia spp.” and “Microthrix parvicella” are the most common sources of activated sludge foaming (there are other non-filament causes of foaming). Both of these filaments are caused by a combination of three factors: high grease and oil content, extended sludge age, and low oxygen levels or septicity.

At higher aeration basin temperatures, Nocardia appears to be preferred, whereas M. parvicella appears to be preferred at lower temperatures. Due to the physical interlocking of the filaments in the foam, antifoam agents are ineffective in controlling this form of foam.

RAS chlorination is ineffective against Nocardia foam, while it is effective against M. parvicella.This is due to the fact that Nocardia is predominantly contained within the floc, and the larger chlorine doses required to kill Nocardia might damage the activated sludge floc. Surface spraying a 50 mg/L chlorine solution on Nocardia foams can be beneficial.

Grease and oil feed both of these filaments. Foaming issues tend to be more prevalent in systems that lack primary clarification (the principal grease and oil removal process). Foaming issues tend to be less prevalent in communities where grease and oil prohibitions are strictly enforced. Treatment of septage, which contains a lot of grease and oil, has also been linked to foaming issues.

Control of Foaming

The filaments' foaming is related to the system's low oxygen level and septicity. Foaming is most commonly controlled by lowering the system MCRT. M. parvicella is generally managed by reducing the MCRT to 8 to 10 days. Nocardia is frequently treated by reducing the MCRT to 8 days, however this is varied and temperature dependent. For Nocardia management, plants in warmer areas have to lower the MCRT to 3 days.

Because they are not cleared, many foams build up on the surface of aeration basins and final clarifiers, causing problems. To transport this material out of the aeration basin or the clarifier, larger surface scum traps and powerful water sprays are required. Foam should be completely removed from the system and should not be recycled (for example, into the headworks). Disposing of foam into aerobic or anaerobic digestors might cause foaming, thus it's best to avoid it.

If you are curious about more information on foaming, then you can have an expert solution upon contacting Netsol Water, a leading manufacturer of Industrial and Commercial Water Treatment Plants and Wastewater Treatment Plants, among other services. Our treatment systems are very effective at removing all types of chemical, physical, and biological pollutants.