Calculations of Jar test: as per Indian Standards

The method for establishing the ideal dose of coagulant (single/mixed), and the ideal pH of coagulation for removing turbidity and colour caused by colloidal and non-settleable particles, followed by sedimentation under quiescent conditions, is prescribed by IS-3025 (Part 50). This Indian standard also gives the Jar test procedure for water and wastewater treatment.

In this blog, we will study the procedure of jar test as per Indian standards for wastewater treatment, and its calculations.

Procedure and calculations of Jar test as per Indian Standards

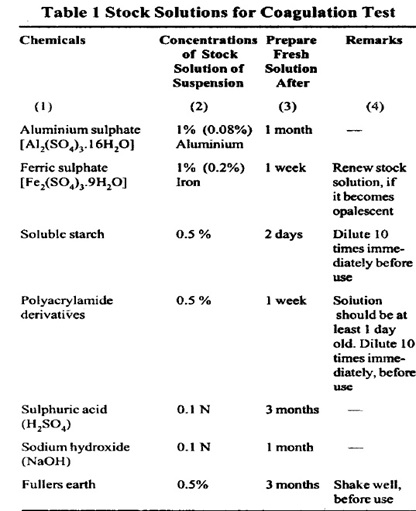

1: Stock solutions of coagulants, coagulant aids, and other chemicals must be prepared at concentrations, which make it simple and precise to quantify quantities appropriate for use in jar tests.

2: (10 x V x d) ml is the volume of stock solution that must be added to a dose of (d/mg) to a volume of (V ml) of sample. Coagulant aids come in both liquid and powder form. When producing reagents with powder aids, care should be taken to add the powder to the distilled water, not the other way around.

3: The dissolution period can be anywhere from a few minutes and several hours. The manufacturer's instructions for this should be properly adhered to.

4: Now, get a sample volume of 10 litres to be examined, and place it (ideally) in a 10 litre polyethylene aspirator. Put the aspirator on its aids and vigorously roll it back and forth, to get the sample homogeneous, before taking it for testing.

5: 800 ml of sample should be measured into 1,000 ml tall form beakers using a measuring cylinder, and then the beakers should be positioned in multiple stirrers with at least a 5 mm space, between the stirrer blade and the inside surface of the beaker.

6: Analyse a 250 ml sample to find out its pH, turbidity, and colour.

7: Make use of a graduated pipette with a 10 ml capacity to transfer the necessary amounts of coagulant, into the coagulant vessels.

8: The temperature should be recorded in one of the beakers before adding the coagulant, and shaking rapidly for at least one minute.

9: Start the stopwatch as soon as the coagulant is added. Add the distilled water used to quickly rinse the coagulant vessels to the beakers.

10: Switch the stirrer to slow one minute after adding the coagulant, and then carefully watch the beakers, noting how long it takes for a pin-point (barely perceptible) floc to appear in each one.

11: Slow stirring for 15 minutes, then turn off the stirrer and carefully remove the beakers from the stirring device.

12: Decant 150 to 200 ml gently from each beaker into a fresh beaker or flask, after letting them stand for 15 minutes.

13: The majority of the time, a decanted sample is adequate, but occasionally it may be discovered to include a small quantity of floc that tends to float. In this case, use a glass syphon to capture a supernatant sample at a depth of 30–40 mm.

14: Samples should be mixed before being measured for turbidity [IS 3025 (Part 10)].

15: Within three hours, measure the samples' colour, turbidity, and pH, and tabulate the results {IS 3025 (Part 4)}.

16: To get the ideal conditions, repeat these steps using various chemical concentrations, flash mix speeds, and settling times.

17: Tests at various pHs can be used to find the optional pH for the coagulants of interest, if one is not already known.

Table: Stock solutions for coagulation test

Specialised wastewater treatment solutions from leading manufacturer and supplier of wastewater treatment plants in India

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment plants and wastewater treatment plants in India.

We also manufacture and supply reverse osmosis plants or RO Plants, effluent treatment plants or ETPs, DM plants, water softeners, Ultra filtration plants or UF Plants, UV water systems, STPs, ZLD plants, and other services. We provide Jar testing services and wastewater treatment solutions to businesses, including automotive, beverages, pulp & paper, refineries, pharmaceutical, textile, hotels, schools, hospitals, office buildings, etc.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.