What is Pulse Flow Reverse Osmosis?

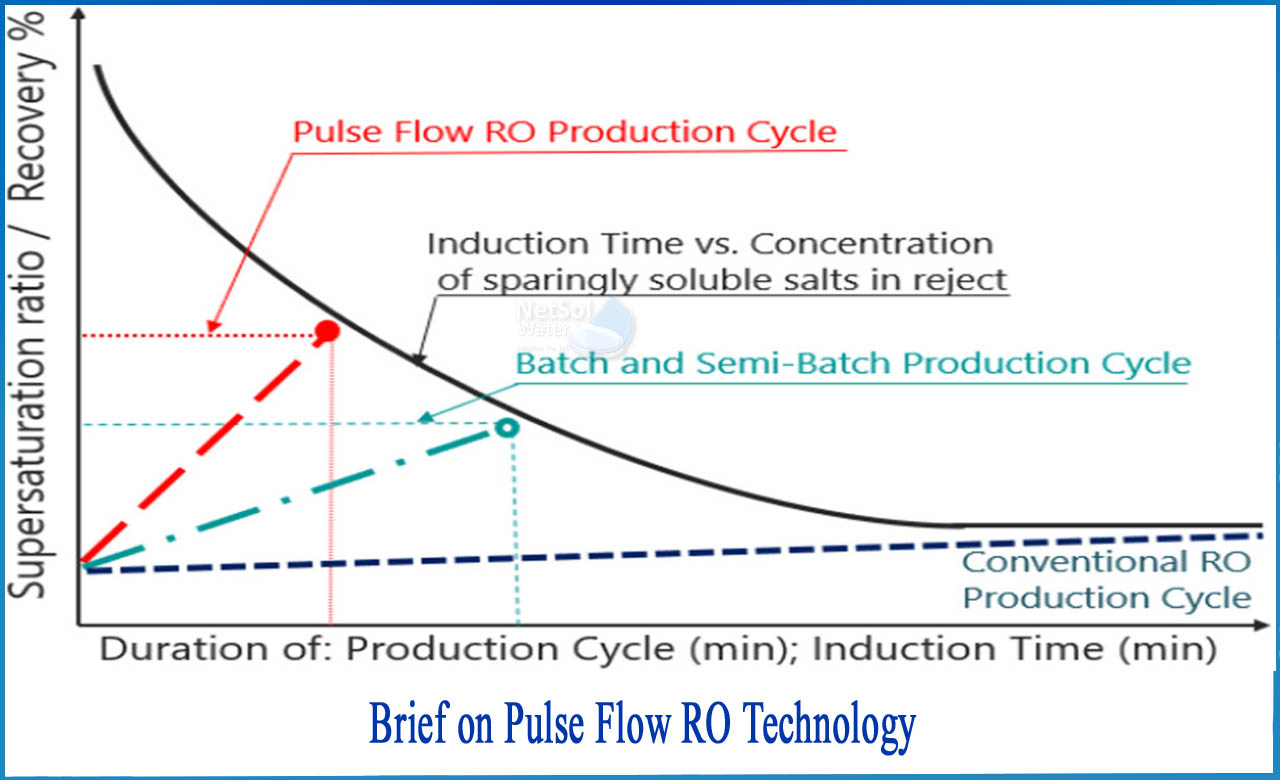

Pulse Flow Reverse Osmosis (PFRO) technology is a new and innovative way to operate reverse osmosis water recycling systems, enabling high recovery, high flow, and chloramine-free operation. PFRO constantly changes osmotic and hydraulic conditions, significantly reducing biofouling and scaling.

PFRO technology was demonstrated at an urban sewage treatment plant in Pismo Beach, California, from October 2018 to October 2019, using secondary wastewater from an urban sewage treatment plant as spring water. The unit operated with a recovery rate of 86% in a single RO stage. No disinfection by-products were formed because chloramine was not administered. The chloramine-free operation produceda permeate with a UV transmission value (UVT) of approximately 100%, with capital and operating costs in the final UV/advanced oxidation process (UV/AOP) phase. Bill was saved by 30-40%. The total water cost of this process was 14-28% lower than a similar standard water reuse process (FAT).

WORKING OF PFRO TECHNOLOGY:

The PFRO process works in two cycles:

(1) Manufacturing cycle and (2) rinsing cycle.

During the manufacturing cycle, the brine valve (attached to the remaining brine flow) is closed, and the brine is not drained. 100% of the feed stream reaches the transparent side. The salt concentration accumulates on the supply membrane side. During the flushing cycle, the brine valve is open for a short time and the brine is drained at high speed.

Following activity occurs in these cycles:

• Brine is delivered in powerful, short pulses.

• The most concentrated brine is discharged.

• The pressure drop of each vessel increases during the purge cycle.

• High brine flow produces many times more shear than traditional RO.

• The quick opening and closing of the brine valve induces pressure strokes and micro-shaking.

• The synergistic cleaning effect of membranes comes from the combination of shear rates, membrane shaking; FO backwash and alternating osmotic and positive pressure.

Membrane parts act as tensioned micro-drumheads. The vibration of these drumheads is believed to be caused by the water hammer that occurs when the brine valve is quickly closed at the end of each flash cycle. In the commercial size RO train, the production and flushing cycle is distributed in the pressure vessel so that the overall supply, permeate, and brine flow is nearly constant over time.

Pressure vessels (PV) are divided into groups. Each group has a single brine valve that opens and closes on a regular basis. In this way, only a small portion of the PV will always be in purge mode. Therefore, the high-pressure pump operates at a stable operating point. All pressure vessels receive the feed stream from the high-pressure pump in parallel, and the production mode pressure vessel continuously produces permeate. The pressure and supply flow rate TDS does not change in the first membrane of the pressure vessel. Fluctuations increase at the end of the pressure vessel.

In contrast to the traditional approach with less RO puffs, PFRO is a one-step RO puff for each recovery.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturer, industrial RO plant manufacturer, sewage treatment plant manufacturer, and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.