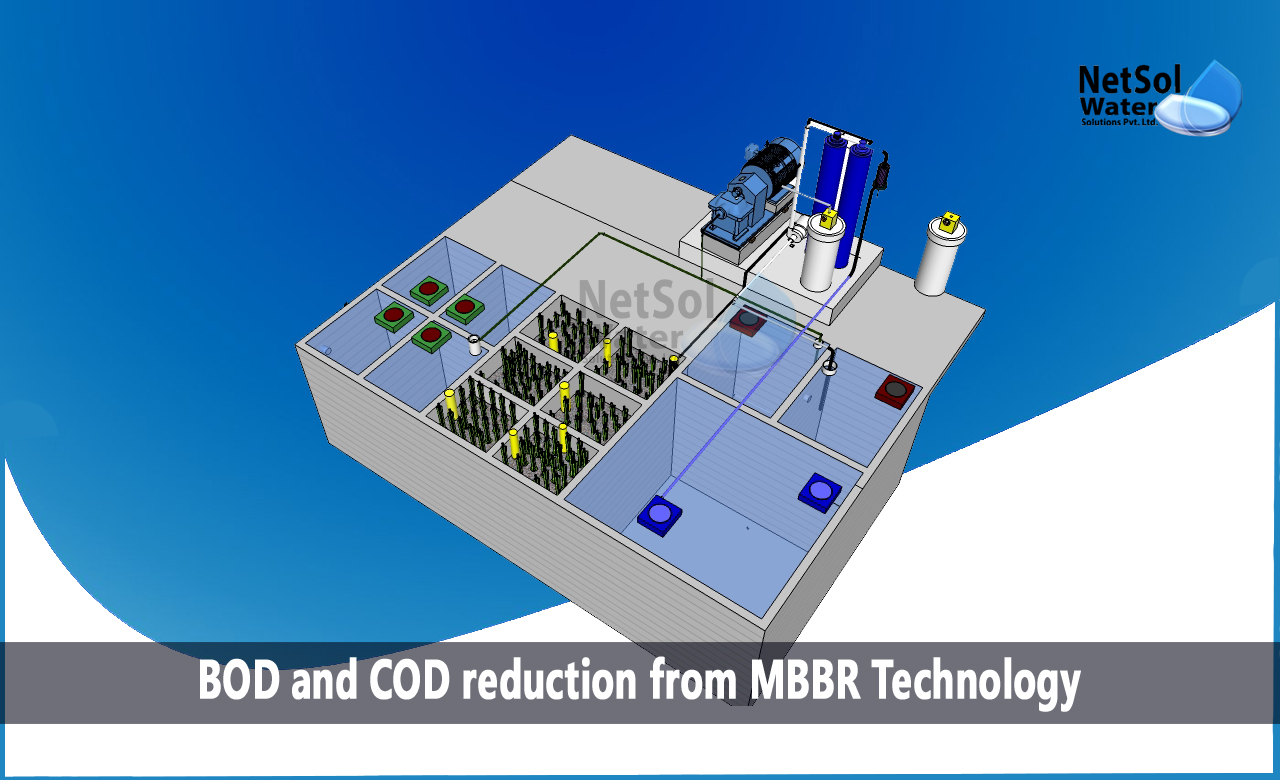

Using the Moving Bed Biofilm Reactor (MBBR) technology, wastewater can be biologically treated. In order to purge contaminants from wastewater, it makes use of microorganisms that develop on a plastic substrate.

Now let’s discuss the percentage of BOD and COD removal that can be achieved using MBBR technology, as well as the different processes that contribute to the reduction of BOD and COD at various steps of the treatment.

Percentage of BOD and COD removal in MBBR technology:

MBBR technology can achieve significant reductions in both BOD and COD levels in wastewater. The percentage of removal depends on several factors, including:

· The characteristics of the wastewater.

· The design of the MBBR system.

· The operating conditions.

Typically, MBBR technology can achieve a BOD removal of up to 95% and a COD removal of up to 90%. However, these percentages can vary depending on the factors mentioned above.

How to BOD and COD reduce from MBBR Technology?

MBBR technology uses several processes to control and reduce BOD and COD in wastewater. These processes include:

· Physical treatment,

· Primary treatment,

· Secondary treatment, and

· Tertiary treatment.

Physical Treatment:

Physical treatment is the first step in MBBR technology, and it involves removing large debris, solids, and other materials that may clog the system. This is typically done through screening and grit removal. Physical treatment does not contribute significantly to BOD and COD removal, but it is an essential step in preparing the wastewater for further treatment.

Primary Treatment:

Primary treatment is the next step in MBBR technology and involves the removal of settleable solids and organic matter that can be easily degraded. This process is achieved through sedimentation and the use of chemical coagulants.

Primary treatment can contribute up to 30% to BOD and COD removal.

Secondary Treatment:

Secondary treatment is the most critical process in MBBR technology and involves the use of microorganisms to remove dissolved organic matter from the wastewater. In MBBR technology, microorganisms grow on plastic media in a suspended growth system. As the wastewater flows through the system, the microorganisms break down the organic matter, reducing the BOD and COD levels.

Secondary treatment can contribute up to 70% to BOD and COD removal, and the level of removal depends on several factors, like:

· Type of microorganisms used,

· The operating conditions, and

· The design of the MBBR system.

Tertiary Treatment:

Tertiary treatment is the final step in MBBR technology and involves polishing the wastewater to remove any remaining contaminants. This process is achieved through several methods, including filtration, adsorption, and disinfection. Tertiary treatment can contribute up to 5% to BOD and COD removal.

Conclusion:

MBBR technology is an effective method for reducing BOD and COD levels in wastewater. It can achieve up to 95% BOD removal and up to 90% COD removal.

The control and reduction of BOD and COD in MBBR technology are achieved through several processes, including physical treatment, primary treatment, secondary treatment, and tertiary treatment.

It’s important to know that the physical treatment and primary treatment do not contribute significantly to BOD and COD removal, but they are essential steps in preparing the wastewater for further treatment.

Secondary treatment is the most critical process in MBBR technology and involves the use of microorganisms to remove dissolved organic matter from the wastewater.

Tertiary treatment is the final step and involves polishing the wastewater to remove any remaining contaminants.

Leading manufacturer of sewage treatment plants in India:

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.