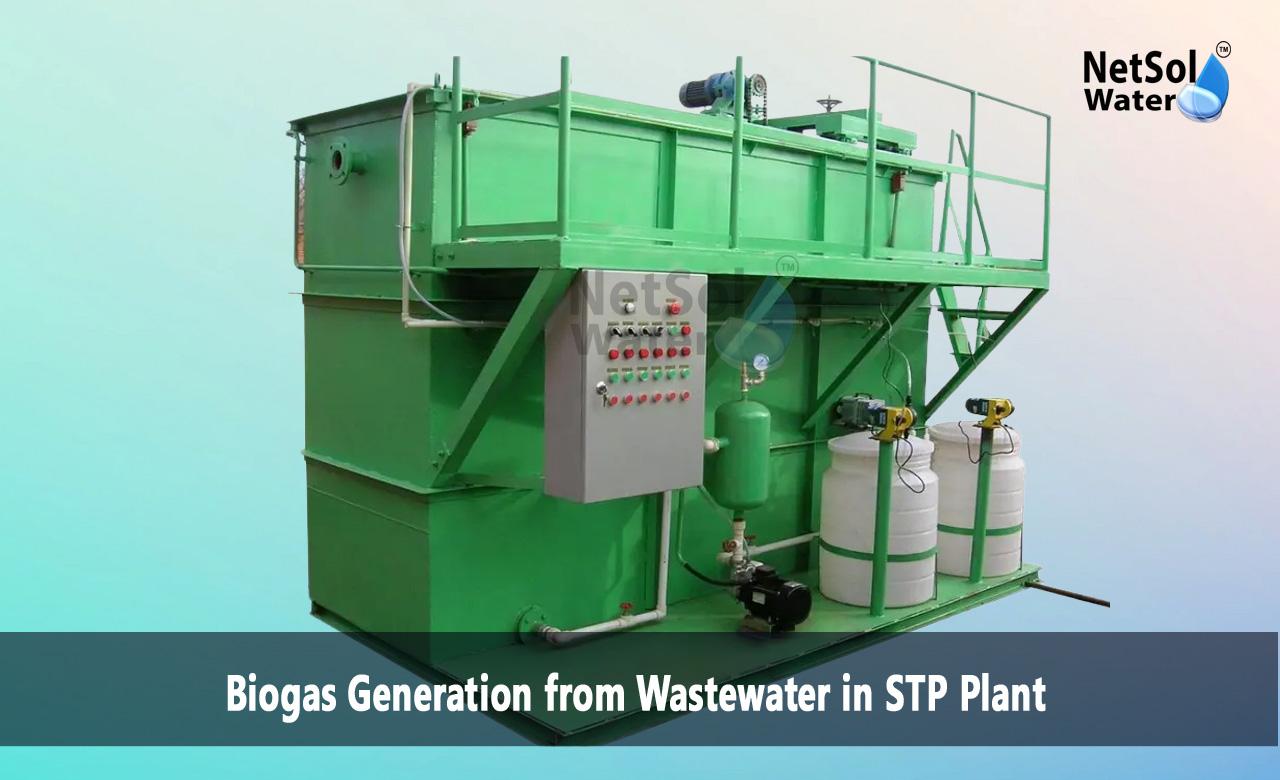

Biogas Generation from Wastewater in Sewage Treatment Plant

Biogas Generation from Wastewater in STPs offers a strong path to turn waste into energy and reduce the load on treatment plants. This process converts organic material in sewage into methane rich gas through biological action. Operators can capture this gas for heat power or for vehicle fuel after cleaning. The approach helps plants lower their energy bills and cut greenhouse gas emissions at the same time. Many cities face growing waste streams and rising energy cost. Bringing biogas systems into sewage treatment plants makes the facility more sustainable and more resilient. The design and operation need careful planning and steady monitoring. Simple changes at the inlet and in the digester can raise gas yield and improve safety.

Feedstock and Waste Characteristics

Organic Load and Composition

High organic load increases potential gas production when digestion proceeds well. Fat, oil and grease raise energy content but they can cause scum and floatation. Food waste and sludge add volatile solids that microbes convert into gas. Monitoring the organic fraction helps managers predict gas output and plan co digestion.

Pre-treatment and Equalization

Pre treatment reduces grit and large debris that harm pumps. Equalization tanks smooth variations in flow and in strength. Stable feed improves microbe health and avoids process upsets. Operators schedule screening and mixing to keep the digester loading steady.

Anaerobic Digestion Processes

Mesophilic and Thermophilic Operation

Mesophilic digesters run at moderate temperatures and they require less energy for heating. Thermophilic digesters run hotter and they speed up conversion. Each mode affects retention time gas yield and pathogen reduction. Plants choose mode based on climate energy cost and treatment goals.

Single Stage and Two Stage Digesters

Single stage digesters keep all steps in one tank and they need less space. Two stage systems separate acid forming and methane forming stages. This separation can boost stability and increase gas production. Pilots reveal which layout fits the available space and the feed mix.

Gas Collection and Utilization

Gas Holders and Safety

Flexible or fixed gas holders collect the produced methane. Plants must control pressure and avoid leaks. Safety measures include gas detection and proper ventilation. A safe design protects staff and nearby communities.

Energy Use and Upgrading

Plants can burn biogas in boilers or engines to make heat and power on site. Upgrading removes carbon dioxide and traces of hydrogen sulfide to make biomethane. Biomethane can feed the grid or serve as vehicle fuel. Choosing the right path depends on demand market and on the quality of raw gas.

Operational Challenges and Solutions

Foaming and Scum Control

Foam and scum form when fats or surfactants enter the digester. These layers reduce active volume and they block gas outlets. Operators use mixing control and they add defoaming feed strategies to prevent buildup. Regular inspection keeps systems healthy.

Temperature and pH Management

Microbes need a narrow range of temperature and pH to work well. Heat loss or sudden feed changes disrupt the balance. Plants install sensors and they use automated controls to keep conditions steady. Rapid response to alarms prevents major upsets.

Economic and Environmental Benefits

Cost Savings and Revenue

Biogas reduces grid energy needs and lowers operating cost. Upgraded gas can bring new revenue when markets allow injection or sale. Grants and carbon credits can shorten payback time. A clear business case helps managers secure support.

Emissions and Resource Recovery

Using biogas cuts methane release and reduces fossil fuel use. Digestate from the process can serve as a soil conditioner after safe handling. This approach closes loops and it supports local circular strategies that save resources and protect water bodies.

Monitoring and Safety

Key Parameters and Instruments

Operators track gas flow, methane content, temperature, pH and volatile fatty acids to assess digester health. Online meters and lab checks work together to reveal trends. Timely data helps staff adjust feed and mixing to keep production stable.

Emergency Planning and Training

Emergency plans prepare staff for leaks flame or equipment failure. Regular drills and clear rules reduce risk and build confidence. Training keeps the team ready to act and to maintain the system long term.

Conclusion

Biogas Generation from Wastewater in Sewage Treatment Plant offers a clear route to turn sewage into energy and to reduce emissions while recovering nutrients. Successful projects depend on good feedstock control, robust digestion design, proper gas handling and steady monitoring. Local conditions and goals shape the best choices. If you seek more information or wish to discuss a site-specificplan contact our team for a consultation. We will review your needs, propose practical steps and help you move toward cleaner energy and stronger plant performance.

Contact Netsol Water at:

Phone: +91-9650608473, Email: enquiry@netsolwater.com