activated sludge process- An overview

Many wastewater treatment systems rely heavily on biological treatment methods. They're one of the most efficient and effective methods for removing organic matter from wastewater. There are a few of them that have been studied and utilised for many decades.

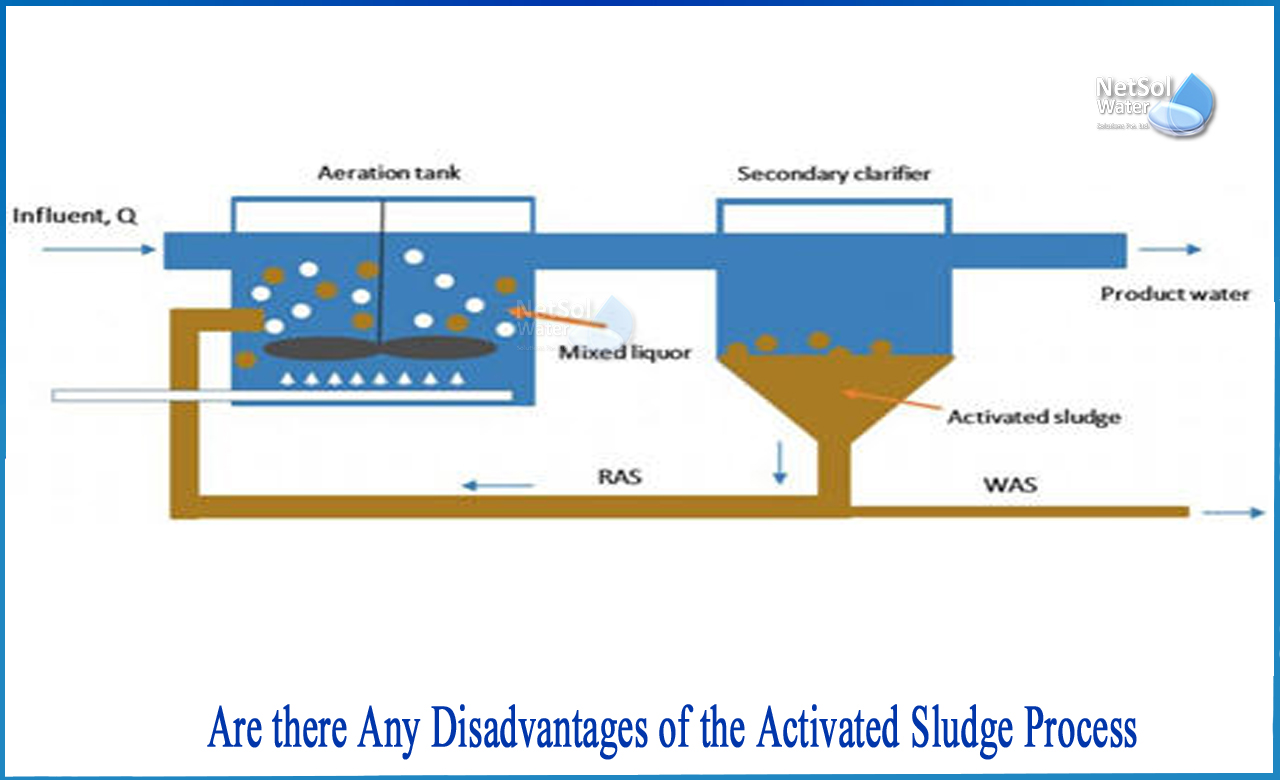

The activated sludge method, on the other hand, is one of the most extensively used traditional biological treatment processes (ASP). Because of the human and animal organic matter in wastewater treatment facilities' input waters, many sewage treatment plants utilise ASP in their secondary treatment phases.

What does “activated sludge” mean?

The phrase "activated sludge" refers to sludge that contains living bacteria and protozoa that actively devour and degrade sewage. In that manner, it differs from the sludge solids recovered after a settling process, with the added benefit of being odourless.

ASP has been shown to produce acceptable results in terms of the treated water's ultimate quality, although it is not without flaws and downsides. Before selecting an activated sludge process (ASP) for municipal treatment, there are various factors to consider.

Are there any disadvantages of the activated sludge process?

We've listed seven possible drawbacks of the traditional activated sludge technique, which will be examined further below-

1:Hydraulic Retention Time

Time is perhaps the most crucial part of any wastewater treatment procedure. Any treatment plan requires time to complete, and some therapies take longer than others. One of these alternatives is ASP. The hydraulic retention time of ASP can take up to several days (3-5) to produce adequate levels of treatment outcomes, depending on the ratio of sewage to sludge and how the process happens.

2: Time for Sludge Retention/Recycling

Time also pertains to the reaction medium. The activated sludge serves as the medium in this situation. In terms of the sludge itself, an ASP is an open system in which the mass rate entering the system differs from the mass rate departing it.Without a recirculation system, the activated sludge in the tank would be flushed away completely over time.

The goal is to have the sludge spend as little time as possible in the system. The reason for recirculation is to guarantee that there is adequate biomass to break down the entering organic materials.As a result, ASP has lower sludge retention durations than most suspended growth biological processes or fixed film processes, such as MBBR.

3: Size

Because of both of the above factors, reactor tanks for the activated sludge process (ASP) are typically rather big in order to handle huge amounts of effluent. This needs a vast amount of land for their operation.

4: Changes in Sewage Volume or Character

ASP can handle huge amounts of diverse organic compounds, but the reaction is highly sensitive on factors, making it prone to mistake under situations other than those for which it was intended.Changes in sewage volume and properties, in particular, might result in worse treatment quality or treatment disturbances. The ASP reactors would normally be required if a treatment facility opted to increase its treatment capacity or began treating wastewater from a new and different source.

5: Getting Rid of Sludge

As is to be expected when dealing with a treatment procedure that employs sludge to treat sewage, large amounts of sludge must be disposed of at the end of the process. Higher disposal costs are connected with larger sludge volumes.

6: Supervision/Operation

Because biology is a complicated subject, it's only natural that a biological water treatment procedure would be complicated in certain ways. On a large scale, the whole procedure appears to be straightforward. The design and operation of an activated sludge reactor, on the other hand, often needs the involvement of specialists in biological systems design. A system like this needs a little more than merely keeping an eye on mechanical faults and monitoring pH.

7: Sludge Settling Problems

The way everything settles out in the secondary clarifying phase reveals some of the most serious difficulties with the activated sludge process. The particles don't always compress nicely at the bottom, and the sludge contains a lot of water.The supernatant (floating particles) may have a greater turbidity than desired, affecting the effluent water quality. Reduced amounts of return activated sludge can be caused by a variety of factors.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.