What are the Applications of UASB Reactor for WWT?

The granulation of biomass is a sign that the UASB reactor is working well!

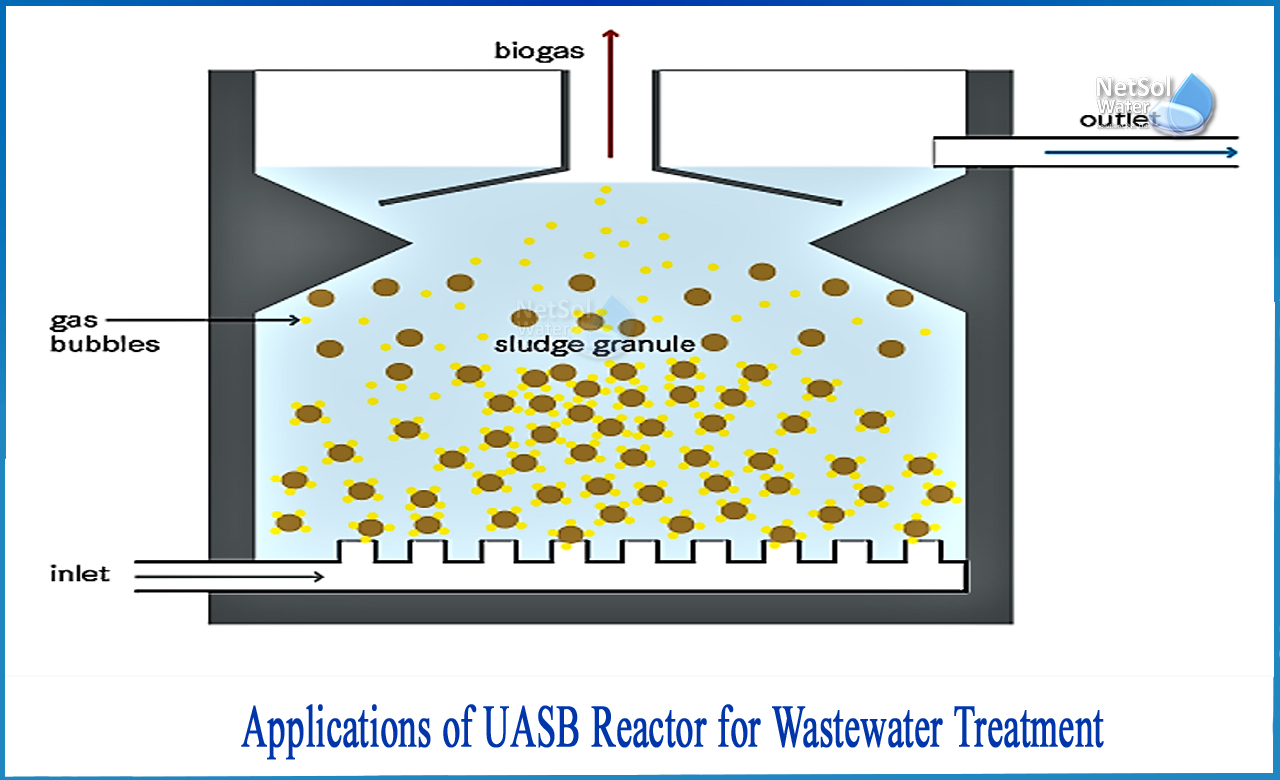

Although satisfactory reactor efficiency may be achieved when the sludge is in a flocculent state, the presence of a granulation sludge configuration has significant advantages. In the granulation process, the composition of wastewater is critical. Carbohydrates or proteins, primarily soluble and potentially colloidal, are substrates that enable granulation. This condition is met by industrial wastewaters from the sugar industry, breweries, apple juice, yeast factory, and grape wine, which granulate in the UASB reactor.

Granulation is suitable for wastewater containing mostly proteins; however, issues may develop due to foaming and protein precipitation under situations of overloading or low pH less than 6.0. More significantly, as they degrade, they emit ammonia, which has the potential to suppress microbial activity. High SS levels in the influent might have a negative impact on granulation and reactor performance.

For the reactor to function properly, the influent SS content must be less than 1 g/L and the SS to COD ratio must be less than 0.5.Granulation will not occur in wastewater containing substrates that do not generate hydrogen during the fermentation process (short chain fatty acids). Granulation is limited in waste when the H2 created is preferentially used by other organisms such as sulphate reducers, e.g., paper pulping waste, due to the limited quantity of H2 accessible to the hydrogenotrophic methanogens. Even when SO4 supplementation is excessive, the granular yield does not drop to zero.

UASB and its successful implementation

Beet sugar, cane sugar, starch, breweries, dairy, tannery, food processing sectors, and paper and pulp are some of the industries where UASB reactors have been claimed to be most successful for wastewater treatment. This method has also been shown to be effective in the treatment of household wastewater. The viability of this procedure has already been demonstrated for the wastewater in a wide range of COD concentrations, from 500 to over 10,000 mg/L. The therapy is possible in both mesophilic and thermophilic environments, although a temperature of at least 15 degrees Celsius is required for successful treatment.

When wastewater is largely biodegradable and COD levels are between 1000 and 5000 mg/L, COD removal efficiency of 85 to 90% may be easily reached with a short HRT of 6 to 12 hours. COD removal effectiveness of 60 to 80 percent can still be accomplished whether the wastewater is complicated or the COD is lower or higher than the above-mentioned range. Once the reactor has been properly started up and excellent quality granular sludge with good settling qualities and activity has been generated, extremely high Organic Loading Rates (OLR) more than 20 kg COD/m3.d can be used.

What are the Operational Modes?

When the mode of operation is intermittent, it also works well for wastewater treatment.

In the case of dairy wastewater treatment, for example, wastewater is created just for a few hours each day and not on a continuous basis. Even in this intermittent state of operation, the process is said to operate well. Also, intermittent operation has been found to be effective in overcoming the problem of sludge caused by inadequate inoculum quality in the early days of operation.

In the event that excessive volatile acids generation occurs in the UASB reactor, lowering the pH below 6.5, an intermittent mode of operation may be used to minimise volatile acids concentration and raise pH in the reactor. The UASB reactor may also be used to treat wastewater from sectors that are seasonal in nature, such as the food processing industry. When the primary start-up of the reactor is complete, and excellent quality granular sludge has developed, the reactor can be shut down at the end of the season.

This secondary start-up, which restores the reactor's COD removal efficiency, takes only a few weeks (1 to 2 weeks) for the reactor that was placed into operation for the new season. Within a week of being shut down for less than a month, the reactor can regain its former COD removal efficiency.

How can Netsol Water help?

If you need help designing an efficient aerobic system, or if you need any information about the application of UASB reactor for wastewater treatment, contact Netsol Water. We can provide you with design calculations, budgetary expenses, preliminary layouts, and a lifetime cost analysis.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.