Overview

After the biological reactor, a secondary sedimentation facility is given to aid in the sedimentation of the cells created during biological oxidation of organic materials. Complete treatment will not be completed if these cells are not eliminated, since they comprise around 40 to 60 percent of the organic matter contained in untreated wastewater in aerobic treatment. Depending on the reactor type, a portion of the settling cells is returned to the reactor, while the remainder is discarded as surplus sludge for further treatment.

Secondary Sedimentation Tanks purpose

After secondary or biological treatment, secondary sedimentation tanks, settling basins, or clarifiers allow microorganisms and other solids to settle. This sludge is poured back into the primary sedimentation tanks' intake end, where it settles with the raw sludge.

There are types of sedimentation processes, depending on particle size and density, as well as the physical characteristics of the solids:

Type 2 — Flocculent and dilute (particles can flocculate as they settle).

Type 3 _ Concentrated suspensions, zone settling, and delayed settling

What is hindered settling or Type-3 settling?

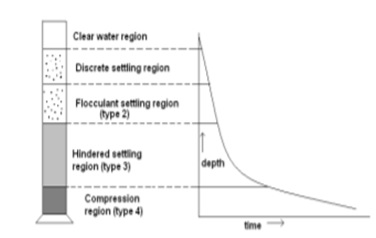

In systems with high suspended solids concentrations, both inhibited (zone) settling (type 3) and compression settling, in addition to discrete and flocculent settling are common. When a concentrated suspension, originally of equal concentration throughout, is put in a cylinder as illustrated in Figure, the settling phenomena occurs.

The liquid tends to migrate up via the interstices of interacting particles due to the high concentration of particles. As a result, the particles form a zone or 'blanket' around each other, preserving the same relative position. This is referred to as 'hindered settling.'

A comparatively clear layer of water forms above the particles in the settling region as the solids settle in a zone. The pace of settling in the impeded settling zone is determined by the solids concentration and features.

In the compression settling area, a compressed layer of particles forms at the bottom of the cylinder while settling proceeds. As a result, a gradation in solid concentration exists in the impeded settling zone, ranging from the interface of the settling region to that found in the compression settling region. Because the composition of solids and their concentrations vary, a settling test is required to evaluate the settling properties.

The laboratory tests can be carried out using two alternative methods.

1. A single settling test (batch), or

2. Method of solid flux (based on a series of experiments with various suspended solids)

The following factors influence the ultimate overflow rate chosen for the sedimentation tank design:

1: Clarification is required in this area.

2: Thickening area required.

3: The pace at which sludge is removed.

Because the free settling zone requires less space than the thickening region, the rate of free settling is rarely the deciding factor. It is possible that the free or flocculent settling velocity of these particles might govern the design in an activated sludge process when light, fluffy floc particles are present.

What can Netsol Water provide?

If you need help designing an efficient sedimentation system, contact Netsol Water Solutions. We can provide you design calculations, budgetary expenses, preliminary layouts, and a lifetime cost analysis.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.