What is Anaerobic Digestion of Sewage Sludge?

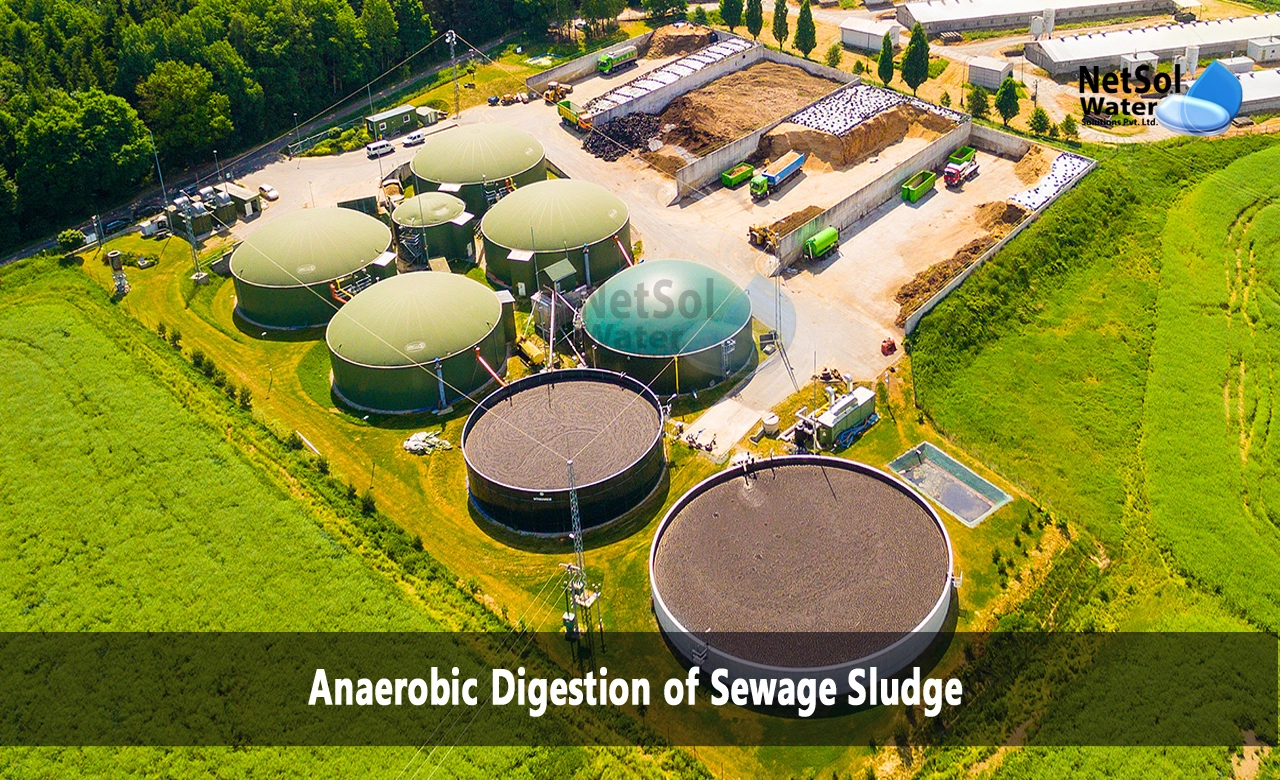

Sewage treatment plants produce immense volumes of sludge - the semi-solid organic residuals resulting from primary settling tanks and biological treatment processes. While dewatering and land filling this sludge was historically common practice, modern wastewater facilities are increasingly adopting anaerobic digestion to stabilize and extract value from these biosolids.

Anaerobic digestion is a biological process harnessing microorganisms to break down organic matter in the absence of oxygen. As the ideal sewage sludge management solution, digestion reduces waste volumes while producing biogas, a renewable energy source. This blog explores how anaerobic digestion works, its advantages over other sludge handling methods, operational parameters, and environmental benefits.

The Biochemistry of Anaerobic Digestion

Sewage sludge comprises complex organic polymers like proteins, fats, and carbohydrates that are hydrolysed into simpler dissolved compounds by enzymes from fermentative bacteria. These soluble monomers become food sources for additional microbes involved in subsequent digestion steps:

Acidogenesis - Acidogenic bacteria convert compounds like sugars and amino acids into volatile fatty acids (VFAs), ammonia, hydrogen, carbon dioxide and other byproducts.

Acetogenesis - Acetogens further digest some of the acidogenic byproducts into acetic acid, hydrogen and carbon dioxide.

Methanogenesis - Finally, methanogens (archaea) convert acetic acid, hydrogen and carbon dioxide into methane biogas and carbon dioxide. Methane production is the ultimate target.

These multistep biochemical transformations occur simultaneously within up-flow anaerobic sludge blanket (UASB) digester vessels designed for optimal bacterial environments. The overall process reduces sludge volumes by 30-60% while capturing biogas at 55-70% efficiency from the influent organic content.

Biogas Composition and End Uses

The biogas captured from anaerobic digesters typically contains 55-65% methane, 35-45% carbon dioxide, trace hydrogen sulfide, moisture and siloxanes. It has around 60-65% of the heating value compared to natural gas once cleaned and compressed.

These renewable biogas streams can be:

1- Combusted directly for process heating within the plant

2- Upgraded into pipeline-quality biomethane by removing CO2

3- Utilized as compressed natural gas vehicle fuel

4- Fired in boilers generating steam/electricity

5- Fuel cells producing electricity and usable heat

The sludge digestion process itself is exothermic, so excess biogas thermal energy often recovers and is circulated back for reactor heating. Some plants integrate nutrient recovery systems, extracting nitrogen and phosphorus fertilisers from digested biosolids.

Advantages Over Other Sludge Handling

As an enclosed treatment process, anaerobic digestion avoids releases of odours, airborne pathogens and greenhouse gases compared to alternatives like sludge drying beds or composting lagoons. Digesters reduce volatile solids content by over 38%, forming stabilised residuals that dewater more efficiently prior to landfilling or land application.

In extracting biogas as a biofuel, the net energy production offsets 50-75% of the digester facility's thermal and electrical demands. This allows wastewater treatment plants to become locally self-sufficient, sustainable utilities while mitigating their overall environmental impacts.

Some plants are even net energy positive by fully utilising all their biogas streams on-site in CHP systems and vehicle fuel. Overall, anaerobic digestion provides a superior multi-pronged sludge handling solution.

Key Operating Parameters

To foster vigorous methanogenic activity within anaerobic digesters, sludge feed rates, temperatures and other operating conditions must stay within ideal ranges:

• Feedstock composition and nutrient balance

• Hydraulic and solids retention times

• pH and alkalinity

• Operating temperatures (mesophilic 35°C or thermophilic 55°C)

• Mixing and solids concentration

• Absence of toxins inhibiting microbes

Instrumentation, piping layouts and control systems carefully monitor and automate these interdependent variables. With proper operating regimens, sewage digesters maximise biogas generation while avoiding acidic conditions toxic to methanogens.

Environmental Benefits

Beyond energy recovery, displacement of fossil fuels and waste stabilisation, anaerobic digestion confers meaningful environmental benefits over sludge disposal alternatives:

• 60-90% reduction in emissions of greenhouse gases and criteria air pollutants

• Decrease in land and hauling required for residual disposal

• Pathogen deactivation producing sanitised biosolids ideal for land application

• Lower overall carbon footprint through net-negative emissions profile

As municipalities target sustainability and resilience goals, anaerobic digesters provide a compelling wastewater biosolids management solution aligned with environmental stewardship. Projected growth in anaerobic digestion technologies holds immense promise, expanding the production of biogas and other value-added products from sewage sludge.

Conclusion

Anaerobic digestion offers sewage treatment facilities a multitude of benefits as the preferred sludge handling strategy. This enclosed biological process reduces sludge volumes while capturing biogas, an exceptional biofuel offsetting a plant's energy footprint. The stabilised residuals dewater efficiently with concentrated nutrients that are recoverable as fertilisers. Optimised digester design and operations ensure Class A biosolids production while mitigating environmental impacts compared to alternative disposal methods.

With world populations surging alongside stricter environmental regulations, anaerobic digestion empowers locally self-sustainable, energy-positive wastewater utilities aligning with circular economy principles. The combination of waste stabilisation, renewable energy generation, and emission reductions position digestion as the premier sewage sludge management solution for municipalities that prioritise resource recovery.

To explore customised commercial RO plants, Industrial RO plants, ETP or STP solutions for your needs in your areas and nearby regions, contact Netsol Water at:

Phone: +91-965-060-8473, Email: enquiry@netsolwater.com