How does anaerobic digestion work?

The process of anaerobic digestion takes place through four successive stages:

Hydrolysis, Acidogenesis, acetogenesis, and methanogenesis.

The anaerobic digestion process is dependent on the contact between the varied microorganisms that are able to carry out the four stages of anaerobic degradation. In single-stage batch reactors, all wastes are loaded concurrently and all four processes are allowed to occur in the same reactorconsecutively. The compost is then emptied after, at the finish of a given retention period or the termination of biogas production for that reaction.

Anaerobic digestion processes

1: Hydrolysis

Anaerobic digesters encounter organic biomass that contains complex polymers which are not readily available to microorganisms without being further broken down through hydrolysis or pre-treatment. As a result, the process of hydrolysis serves the purpose of rendering organic macromolecules into its smaller components, which in turn can be utilized by acidogenic bacteria. While hydrolysis is as an electrochemical process, in anaerobic digestion, it mostly exists as a biological one.

In the process of hydrolysis, hydrolytic bacteria are able to produce extracellular enzymes that convert carbohydrates, lipids, and proteins into sugars, long chain fatty acids (LCFAs), and amino acids. After enzymatic action, the products of hydrolysis are able to diffuse through the cell membranes of acidogenic microorganisms. However, it must be noted that certain substrates, such as lignin, cellulose, and hemicellulose, may find it difficult to decompose, and can be inaccessible because of their complex structures. Enzymes are often added to support the hydrolysis of these carbohydrates.

Hydrolysis is a rate-determining step!

As hydrolysis is important in the kinetics of anaerobic digestion, a great deal of attention has been turned towards methods for promotion of hydrolysis in anaerobic digesters. A variety of waste pre-treatment options are being researched and utilized to optimize hydrolysis, especially for digesters that digest heavily lingo-cellulosic wastes. Hydrolysis has, on its own, an optimum temperature between 30–50 ?C and with an optimum pH of 5–7.

2: Acidogenesis

By absorbing the products of hydrolysis through their cell membranes, acidogenic microorganisms produce intermediate volatile fatty acids (VFAs) and other products. VFAs constitute a group of organic acids such as acetates and larger organic acids such as propionate and butyrate,mostly in a ratio varying from 75:15:10 to 40:40:20. Even then little amounts of ethanol and lactate may be present.

The specific concentrations of intermediates produced in the Acidogenesis stage may depend on the conditions of the digester; it has been found that VFA concentrations can fluctuate significantly for digesters operating at different pH.

As opposed to other stages, acidogenesis proceeds at a faster rate than all other stages of anaerobic digestion, with acidogenic bacteria having a regeneration time of fewer than 36 h. With the rapid speed of this stage in mind, it is important to note that while the production of VFAs creates direct precursors for the final stage of methanogenesis, VFA acidification causes digester failure.

3: Acetogenesis

With the production of acetate through acidogenesis, a portion of the original substrate has already been changed into a substrate suitable for acetoclastic methanogenesis. However, other produced higher VFAs are yet to be made accessible to methanogenic microorganisms.

Acetogenesis is the process by which these higher VFAs and other intermediates are transformed into acetate, with hydrogen also being produced. While acetogenesis is a producer of hydrogen, an excessive partial pressure proves to be adverse to acetogenic microorganisms.

However, due to the presence of hydrogenotrophic methanogens, hydrogen is consumed rapidly while maintaining hydrogen partial pressures at a level favourable to acetogenesis by creating an exergonic reaction.At the same time, lipids follow a separate pathway of acetogenesis via acidogenesis and β-oxidation, where acidogenesis generates acetate from glycerol and β-oxidation produces acetate from LCFAs.

4: Methanogenesis

Methanogenesis is the final stage of anaerobic digestion, where accessible intermediates are consumed by methanogenic microorganisms to produce methane. Methanogenic microorganisms represent a group of obligate anaerobic ‘Achaea’. Methanogenic microorganisms are extremely sensitive to oxygen. In addition to a sensitivity to oxygen, methanogenic microorganisms are limited to a small selection of substrates.

Typically, acetoclastic methanogenesis from acetate accounts for almost 2/3 of the methane production, with hydrogenotrophic methanogenesis accounts for almost all the remaining 1/3 of the methane production; however, methanogenesis from methanol, methylamines, and formate can be found.With regards to the environmental needs of methanogenesis, methanogenic microorganisms require a higher pH than previous stages of anaerobic digestion.

At the same time, methanogens appear to have a significantly slower regeneration time than all the other microorganisms in anaerobic digestion. However, it has been reported that some hydrogenotrophic species, such as Methanococcus maripaludis, have a doubling time of only two hours. In batch reactors, the end of methanogenesis is established when biogas production stops, which can take about 40 days. Evaluations of a sludge’s extent of digestion can be taken from its volatile solids content and its ability to dewater.

Conclusion

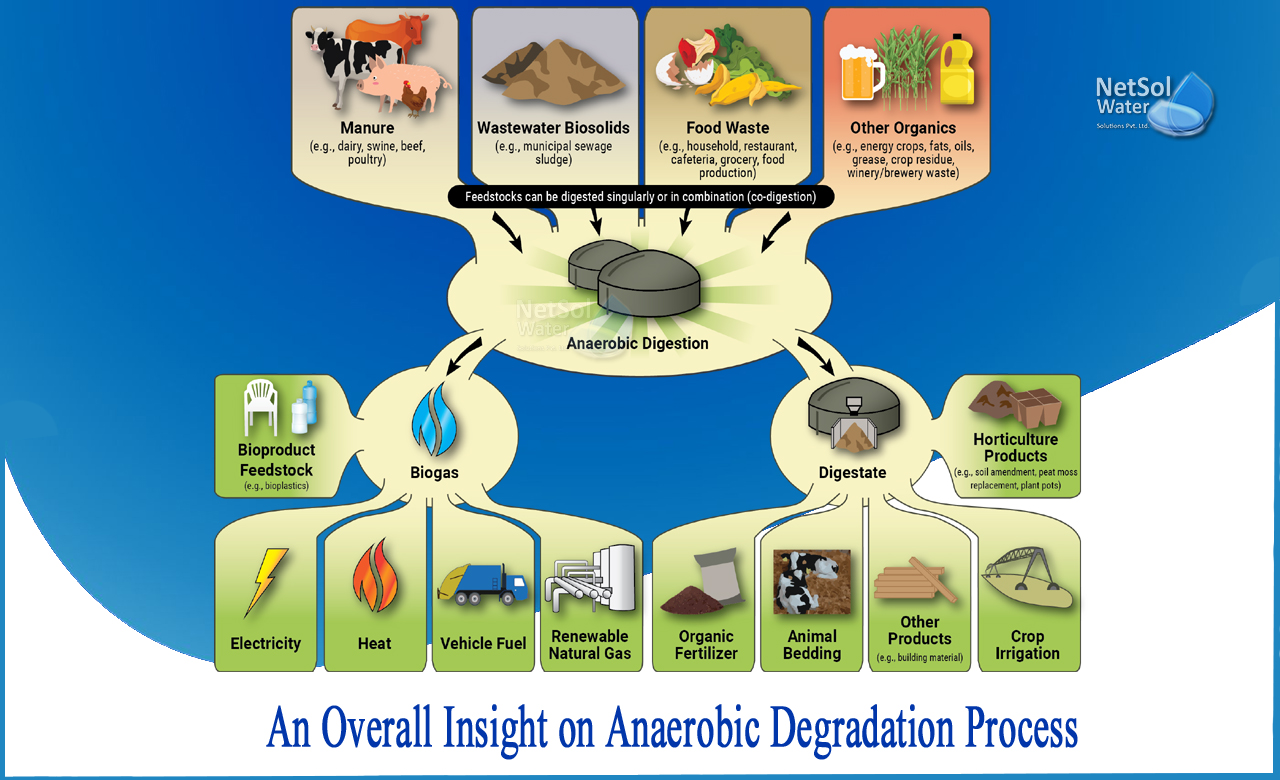

The anaerobic digestion process follows the above mentioned four processes and generates bio-fuels. This method has lots of advantages and pros, so it should be in popular use in waste management systems as it serves the purpose of generating energy from waste.

What can Netsol Water offer?

Netsol is India’s leading water and wastewater treatment solution company which covers all the needs of any water treatment scheme on all levels. We have the expertise to provide wastewater solutions at domestic, industrial and municipal levels.

Contact us for consultations as well as to clear up all your queries about wastewater and its treatment process, methods and cost optimisation in construction and management of the system.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.