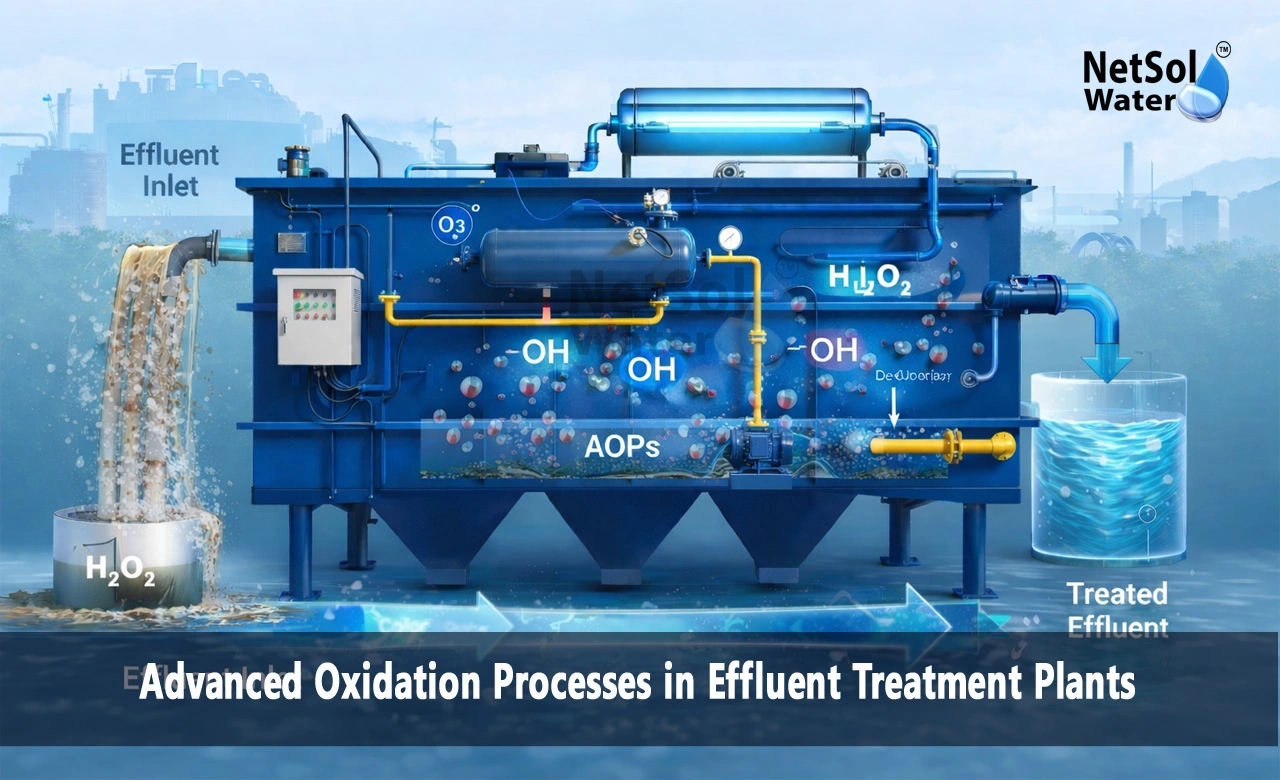

Advanced Oxidation Processes in Effluent Treatment Plants

Complex and refractory pollutants are increasing and there is a need to treat effluent in ETPs, which cannot successfully be eliminated using the traditional biological or physico-chemical methods. Other industries like pharmaceuticals, textiles, chemicals and specialty manufacturing emit effluents that have persistent organic compounds, color bodies, toxic intermediates, and micro-pollutants. In such scenarios, Advanced Oxidation Processes in Effluent Treatment Plants have emerged as a critical polishing and treatment solution. These are dependent on the production of highly reactive oxidizing species, which are mostly hydroxyl radicals, which are able to decompose complex organic molecules reducing them to simpler and biodegradable molecules.

The Failure of Conventional Treatment Methods

1: Disadvantages to Biological Treatment

Biological systems can handle biodegradable organic matter but cannot handle high COD fractions which are a toxic, non-biodegradable or inhibitory to microorganisms. Most of the industrial effluents have compounds that are not degraded adequately in the biological units, resulting in poor quality of final discharge.

2: Limitations of Physical and Chemical Procedures

Coagulation, adsorption and filtration are processes that are involved in the removal of suspended and colloidal materials but not dissolved organic pollutants. These techniques usually pluck the contaminants out of one level to another instead of destroying them, and thus pose a disposal problem.

3: Theory Advanced Oxidation Processes

Advanced oxidation process involves the generation of strong oxidants which are hydroxyl radicals that are of extremely high oxidation potential. These radicals do not discriminate organic pollutants, which are dissected to form carbon dioxide, water, and other basic intermediates, in complex molecular structures. AOPs can also effectively improve biodegradability as opposed to full mineralization, and downstream biological treatment is more efficient in most instances.

Typical Advanced Oxidation Processes in ETPs

1: Ozonation-Based Oxidation

Ozone is an effective oxidant, which directly reacts with organic compounds or decomposes to produce hydroxyl radicals when the appropriate conditions exist. Ozonation is commonly used in the tertiary or polishing stage in effluent treatment plants to minimize color, odor and residual COD. It is dependent on contact time and dose of ozone and the composition of the wastewater.

2: Oxidation Using Hydrogen Peroxide

Hydrogen peroxide is a weak oxidizer that is effective when used together with catalysts or UV radiation. In ETP, complex organic loads in the industrial effluents are usually treated through peroxide-based oxidation in the presence of biological treatment.

3: Fenton and Photo-Fenton Processes

Fenton process entails reaction of hydrogen peroxide and iron salts to produce hydroxyl radicals. It works especially with industrial wastewater that is high COD and has refractory compounds. Photo-Fenton systems also increase the effectiveness of oxidation by applying light to regenerate iron catalysts and promote the production of radicals.

4: UV-Based Advanced Oxidation

Radical generation is increased by the use of ultraviolet radiation along with oxidants like hydrogen peroxide or ozone. The AOPs are effective in the treatment of low turbidity effluents and elimination of trace organic contaminants and pathogens, particularly the use of UV-based AOPs.

Applications of Advanced Oxidation Processes in Effluent Treatment Plants

Advanced Oxidation Processes in Effluent Treatment Plants are widely used in pharmaceutical manufacturing to remove active drug residues and antibiotic compounds. AOPs are used in textile and dyeing industries to remove stubborn color and dye molecules which are not biodegradable. The processes are applied in chemical and specialty industries to diminish toxicity and enhance the overall treatability of effluents prior to discharge or reuse.

Design Concerns and Operational Difficulties

1: Energy and Chemical Consumption

AOPs are energy consuming and need optimization to ensure a good balance between treatment and operation cost. Overdose of chemicals or over-oxidizing may cause a substantial rise in operation costs.

2: Wastewater Matrix Interference

Scavengers, including bicarbonates, chlorides, and suspended solids, are capable of decreasing the effectiveness of oxidation, by absorbing the hydroxyl radicals. It should be treated well in order to have consistent performance.

3: Monitoring and Control of Processes

High-order oxidation systems need a very accurate regulation of the pH, dose of oxidant, reaction time, and the concentration of catalysts. Poor monitoring usually contributes to low performance or wastage of chemicals.

APOs in the Integrated Treatment Systems

Rather than replacing conventional treatment, Advanced Oxidation Processes in Effluent Treatment Plants work best as part of an integrated system. As a pretreatment, they enhance biodegradation and defend biological units. They assist in meeting high discharge or reuse standards as a post-treatment measure to eliminate any residual pollutants.

Conclusion

Advanced Oxidation Processes in Effluent Treatment Plants play a major role in addressing the limitations of conventional wastewater treatment technologies. AOPs allow industries to attain a higher degree of treatment, regulatory compliance and reuse readiness by targeting refractory and toxic organic pollutants. Although these processes need to be carefully designed, controlled and cost managed, they cannot be ignored in the current effluent treatment plans due to their qualities of disintegrating complex contaminants. Advanced oxidation will remain an important element of sustainable industrial wastewater management as discharge norms grow increasingly stricter and the reuse of wastewater becomes more significant.

Do you need an advice or assistance on selecting the best water and waste water treatment unit? We have solutions for all your problems!

Let us know your problem, our experts will make sure that it goes away.

For an assistance or related query,

Call on +91-9650608473 Or write us at enquiry@netsolwater.com