15000 LPH Commercial RO Plant Price and Process details

Reverse Osmosis (RO) is a widely used water treatment technology, especially in commercial and industrial sectors. A commercial RO plant is designed to purify large volumes of water for various industrial processes.

Here we will discuss a 15000 LPH RO plant, its price, process flow diagram, and details.

What is a 15000 LPH RO Plant?

A 15000 LPH RO plant is designed to treat 15,000 liters of water per hour, making it suitable for large-scale industrial applications. The plant uses the reverse osmosis process to remove impurities, such as dissolved salts, minerals, and other contaminants from water. The system consists of several components, including pumps, membranes, pressure vessels, and a control system, to ensure efficient and reliable water treatment.

15000 LPH Commercial RO Plant Price:

The price of a 15000 LPH RO plant depends on various factors, such as the quality of components, design, and features. However, the average cost of a commercial 15000 LPH RO plant would start around 15 Lakh Rupees, depending on the supplier and customization requirements.

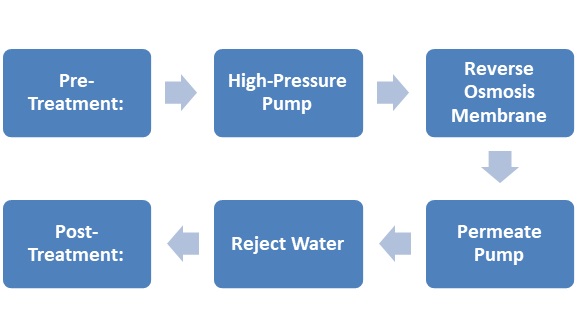

15000 LPH Commercial RO Plant Process Flow Diagram:

The process flow diagram of a 15000 LPH RO plant is as follows:

· Pre-Treatment: The first step of the RO process is pre-treatment, which involves removing large particles and suspended solids from the water. This is done by passing the water through a series of filters, including sand filters, multimedia filters, and activated carbon filters.

· High-Pressure Pump: The pre-treated water is then fed into a high-pressure pump that increases the pressure to the required level for the RO process.

· Reverse Osmosis Membrane: The water is then passed through a reverse osmosis membrane, which separates the dissolved salts, minerals, and other contaminants from the water.

· Permeate Pump: The purified water, known as permeate, is collected and passed through a permeate pump, which increases the pressure for further treatment or distribution.

· Reject Water: The rejected water, containing the concentrated contaminants, is discharged or recycled, depending on the treatment requirements.

· Post-Treatment: The final step of the RO process is post-treatment, which involves adding chemicals, such as disinfectants, pH stabilizers, and remineralizers, to ensure the water is safe for consumption or suitable for industrial applications.

Summary:

A 15000 LPH RO plant is an essential water treatment technology for large-scale industrial applications. The system uses the reverse osmosis process to remove impurities and contaminants from water, making it safe for consumption or suitable for industrial processes. The price of a 15000 LPH RO plant varies depending on the quality of components, design, and features, but it generally starts from 1500000 INR. The process flow diagram of a 15000 LPH RO plant involves pre-treatment, high-pressure pumping, reverse osmosis membrane separation, permeate pumping, reject water discharge or recycling, and post-treatment. The system components include pre-treatment filters, a high-pressure pump, RO membrane pressure vessels, and a control system. Overall, a 15000 LPH RO plant is a reliable and efficient solution for water treatment in various industrial applications.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.