What is Working of Zero Liquid Discharge Systems?

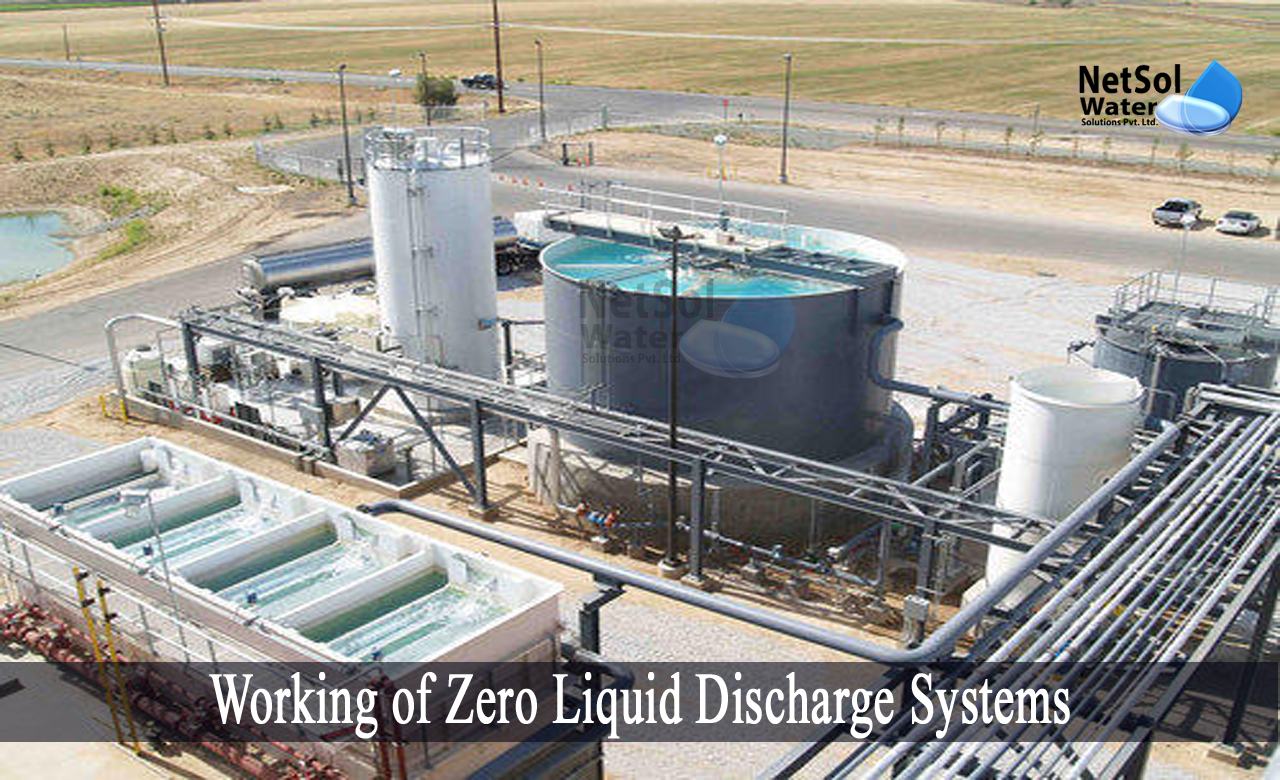

Every industry generates several sorts of wastewater, each with its own difficulties. Netsol Water is equipped with the knowledge, know-how, and technology necessary to treat a wide range of wastewater. Through water filtration, evaporation, and sludge dewatering, Zero Liquid Discharge is achieved. Our ZLD systems include reverse osmosis (RO), deionization, and ultrafiltration (UF). Both thermal and atmospheric evaporators are also included.

With every technology, comes its working. In this blog, we will discuss about the working of Zero Liquid Discharge Systems.

Working of Zero Liquid Discharge (ZLD) systems

Although specific procedures for treatment vary, a common ZLD treatment procedure often entails the following steps:

· Conditioning and preparation

Step-1:Pre-treatment is used to condition the water and reduce suspended solids and materials, that may otherwise scale and foul subsequent treatment procedures. It removes simple substances from the wastewater stream, which can be filtered out or precipitated out.

Step-2:Usually, the clarifier or reactor in the treatment block precipitates out the metals, hardness, and silica.

Step-3:In order to facilitate the coagulation process, which involves adding various chemicals to a reaction tank, in order to remove the bulk suspended particles and other pollutants, this stage occasionally calls for the use of caustic soda or lime. This procedure begins with a variety of mixing reactors, usually one or two reactors that add particular chemicals, to remove all of the smaller water particles by combining them into larger particles that settle out.

Step-4:When coagulation is finished, the water enters a flocculation chamber, where long-chain polymers are slowly stirred in to combine the coagulated particles, resulting in visible, settleable particles.

Step-5:Flocculated material and water enter the chamber of the gravity settler, or sedimentation component of the ZLD treatment process, and circulate outward from the centre. The sediments slowly settle to the bottom of the clarifier, and form a sludge blanket as a result of the water rising to the top, and overflowing at the clarifier's edge.

Step-6:The sludge is then pushed out of the bottom of the clarifier into a sludge-handling or dewatering operation, after the solids are slowly mixed in the centre of the clarifier in a cylindrical tube. For a reduced footprint, the settlers can also be created using a plate pack.

· Concentration in phase one

Reverse osmosis (RO), brine concentrators, or electro dialysis membranes, are frequently used for concentration in the early phases of ZLD.

Step-1:The majority of the dissolved solids that pass through the process will be captured by the RO. On the other hand, brine concentrators can often handle brine with a significantly higher salt content than RO, and are also used to remove dissolved solid waste. They produce a reduced volume of waste fairly well.

Step-2: The ZLD treatment system also allows for the use of electro dialysis. It is a membrane method that may be applied in phases to concentrate the brine, and uses positively or negatively charged ions to allow charged particles to pass through, a semipermeable membrane. It frequently works in tandem with RO to get incredibly high recovery rates.

Together, these methods can concentrate this stream's salinity down to a high level, while removing between 60 and 80 % of the water.

· Evaporation/crystallization

Step-1:The process of creating a solid, which comes after concentration, is carried out through heat processes or evaporation, in which all the water is removed, collected, and used again. By adding acid now, you can neutralize the solution, and prevent scaling and damage to the heat exchangers when heating it. To release dissolved oxygen, carbon dioxide, and other non-condensable gases during this stage, de-aeration is frequently utilized.

Step-2:The remaining waste is then transferred from an evaporator to a crystallizer, where it is heated until all the water has been removed, and all the contaminants have crystallised, filtering out as a solid.

· Distribution of recycled water and solid waste management

The cleaned water is often pumped into a holding tank where it can be used as needed, by the facility if it is being re-used in an industrial operation. Water should have been sufficiently filtered by the ZLD treatment system, to be reused in your process without risk.

· Dewatering process

At this point, the solid waste will start the dewatering process, which uses filter presses or belt presses, to squeeze all the water out of the sludge and produce a solid cake. The sludge is placed into the press and flows between two belts. It compresses the water out before being placed into a large hopper, which either travels to a landfill, or a facility that reuses it. Water produced by this technique is also re-used.

In summary

Netsol Water has more than 10 years of experience in custom-designing, and producing industrial wastewater treatment systems. In order to schedule a call with an engineer, or submit a quote request, you can also visit our website. We can guide you through the process of coming up with the best solution, and a reasonable price for your ZLD wastewater treatment system requirements.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.