What is the Work of Sequencing Batch Reactor?

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process designed to operate under non-steady state conditions for the treatment of wastewater in small package plants and for centralized treatment of sewage.

In this system, wastewater is added to a sequential batch reactor to remove undesirable components and then discharged. For optimizing the performance of the system, two or more batch reactors are used in a predetermined sequence of operations. SBR systems are used for treatment of both municipal and industrial wastewater. They are suited for wastewater treatment applications for low or intermittent flow conditions.

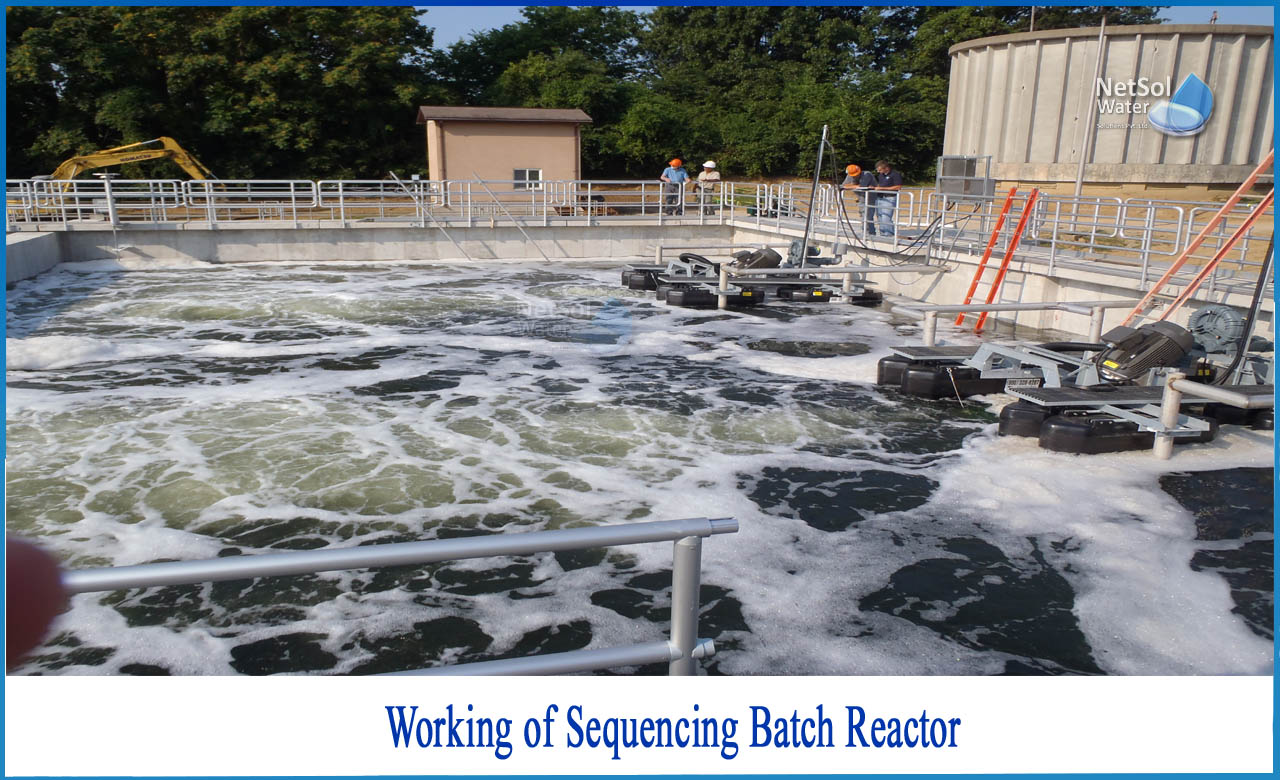

Working of SBR

SBR is used in small packaged plants. The SBR system consists of a single mix reactor in which all the steps of the activated sludge process takes place.

The working of SBR takes place in following sequence:

Step 1-The influent wastewater is distributed uniformly through the influent distribution manifold to establish good contact between the microorganisms and the substrate. The influent wastewater can be either pumped in or allowed to flow in by gravity. For the fill phase with a fixed duration,the SBR system can be designed to have a continuous influent, eliminating the need for an upstream buffer tank. For the fill phase with a variable duration, an upstream buffer tank is required.

Step 2- After reaction basin is filled, aeration is started. And air is introduced into the wastewater through an array of diffusers, providing oxygen for aerobic biological reactions. Mixing is done to ensure uniform aeration throughout the volume of the tank. The reactor basin is filled for 3 hoursand then aerated for a period of 2 hours usually.

Step 3-After the aeration cycle is complete, the reactor is allowed to settle for duration of 0.5 h. In some designs, the settle phase runs in parallel with a fill phase.

Step 4-After this, effluent is decanted from the top of the unit, which takes approximately 0.5 h. Fixed or floating decanter mechanism is adopted for decanting of supernatant. Withdrawal of treated effluent takes place from two feet below the surface of the mixed liquor by the floating solids excluding decanter. Without disturbing the settled sludge, effluent is withdrawn.

Step 5-After decanting cycle is complete, the reactor is filled again with raw sewage and the process is repeated.

Step 6-An idle step occurs between decant and fill phases. The duration of idle step varies based on the influent flow rate and operating strategy. A small quantity of activated sludge is wasted from the bottom of the SBR basin.

Step 7-A large equalization basin is required in this process since the influent flow must be contained while the reactor is in the aerating cycle.

These processes are popular because one reactor basin is used in the entire process. When spaceavailable is less, treatment takes place in a single basin. Use of effective decanters eliminate the need for a separate clarifier. Also, low total suspended solid values of less than 10 g/m3 can be achieved. The treatment cycle can undergo aerobic, anaerobic, and anoxic conditions in order to achieve biological nutrient removal including nitrification, denitrification, and some phosphorus removal. According to the needs of the particular treatment plant, duration, oxygen concentration, and mixing in these periods can be altered. Aeration and decanting is essential for proper operations of these plants. The aerator helps in making the oxygen readily available to the microorganisms.

Advantages and disadvantages of SBR

Listed below are some of the advantages and disadvantages of SBRs

Advantages

i) Equalization, biological treatment, and secondary clarification can be achieved in a single reactor basin.

ii) There is flexibility and control in operation.

iii) Cost savings by eliminating use of clarifiers and other equipment.

Disadvantages

i) A higher level of sophistication is required as compared to conventional systems.

ii) Higher level of maintenance due to more sophisticated controls, automated switches, and automated valves is required.

iii) Plugging of aeration devices during selected operating cycles is required.

iv) There is aneed for equalization after the SBR depending on the downstream processes.

How can Netsol Water help you?

Netsol Water is one of the leading water and wastewater treatment company in India with services in the field of WTP manufacturing, WWTP manufacturing, STP manufacturing, among other services. The company designs and manufactures all in one systems that are ideal for treating wastewater and the sludge generated and not only turns your wastewater into usable water but also acts as a savior of Mother Earth and its precious resource “water”.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.