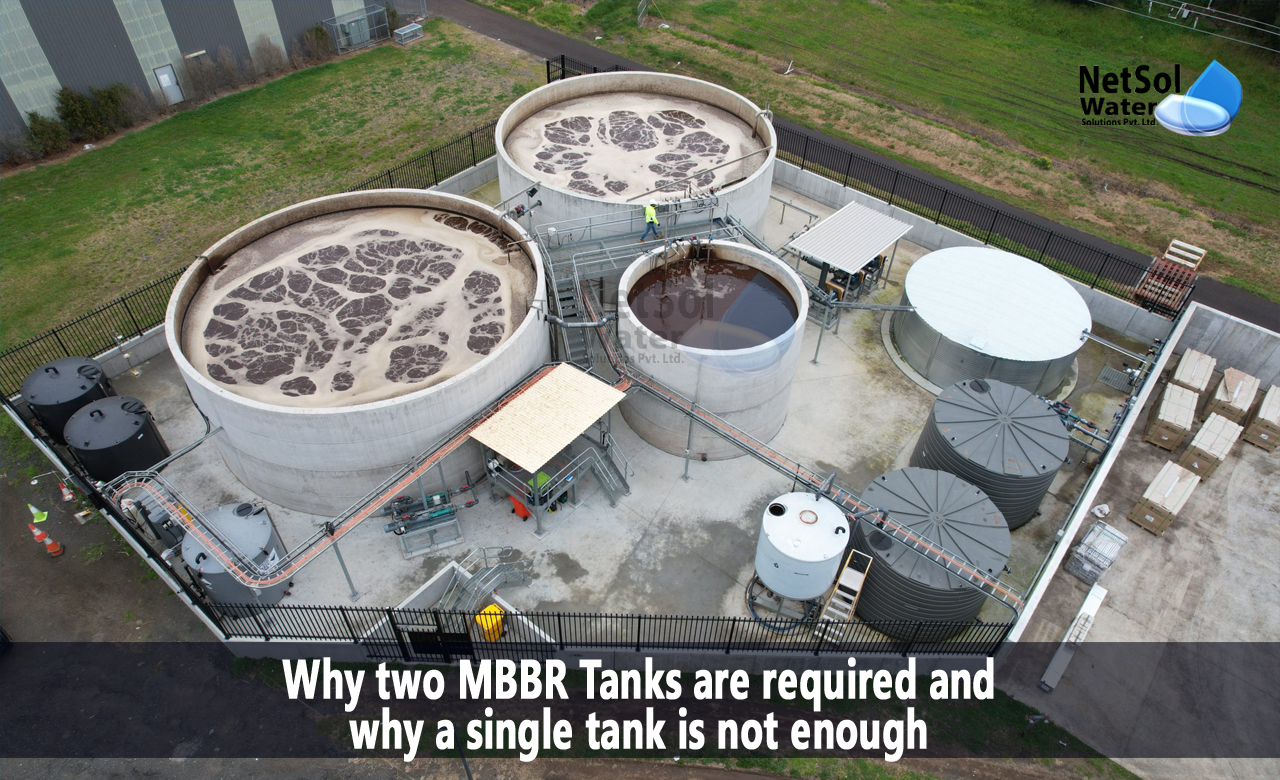

Why two MBBR Tanks are required and why a single tank is not enough?

Moving Bed Biofilm Reactor (MBBR) is a biological wastewater treatment process that uses microorganisms attached to a carrier media in a suspended growth system. The MBBR process is commonly used to remove organic matter, including Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) from wastewater or sewage.

MBBR tanks are a common treatment option for municipal and industrial wastewater treatment facilities. This article discusses why two MBBR tanks are required to control or reduce BOD and COD of sewage and why a single MBBR tank is not sufficient for the task.

What is BOD and COD?

Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) are two commonly used measurements for determining the amount of organic matter in wastewater.

BOD is a measure of the amount of oxygen required by microorganisms to break down the organic matter in wastewater.

COD is a measure of the amount of oxygen required to oxidize the organic matter in wastewater chemically. Both measurements are useful for determining the amount of organic matter in wastewater and for designing treatment processes to remove it.

Why two MBBR tanks?

Moving Bed Biofilm Reactors tanks are designed to provide an environment for microorganisms to attach to the carrier media and break down organic matter in wastewater or sewage.

When wastewater flows into the first MBBR tank, microorganisms begin to attach to the carrier media and break down the organic matter. As the microorganisms grow and reproduce, they begin to slough off the carrier media and flow into the second MBBR tank.

The second MBBR tank provides an environment for the microorganisms to further break down the organic matter in wastewater. By the time the wastewater flows into the second MBBR tank, the microorganisms are more mature and can break down the organic matter more efficiently.

Using two MBBR tanks in series provides several benefits:

Using two MBBR tanks rather than one in series provides several benefits such as:

1. Reduces the loading rate: By using two MBBR tanks, the loading rate is reduced for each tank, which allows the microorganisms to break down the organic matter more efficiently.

2. Provides redundancy: If one MBBR tank fails, the second MBBR tank can continue to treat wastewater, reducing the risk of a treatment system failure.

3. Improves treatment efficiency: By providing an environment for the microorganisms to mature, the second MBBR tank can more efficiently break down the organic matter in wastewater.

Why a single MBBR tank is not sufficient for the task?

While a single MBBR tank can remove organic matter from wastewater, it is not sufficient to achieve the desired level of treatment efficiency. A single MBBR tank has several limitations:

1. High loading rate: A single MBBR tank has a higher loading rate, which reduces the efficiency of the treatment process. High loading rates can also lead to the accumulation of organic matter in the tank, which can lead to odors and other operational problems.

2. Limited capacity: A single MBBR tank has a limited capacity for microorganisms, which can limit the treatment efficiency. When the tank reaches its capacity, the microorganisms can become stressed and may not be able to break down the organic matter effectively.

3. Risk of system failure: If a single MBBR tank fails, the entire treatment system can fail, leading to a discharge of untreated wastewater.

Conclusion:

Moving Bed Biofilm Reactor tanks are an effective treatment option for reducing BOD and COD in wastewater. Using two MBBR tanks in series provides several benefits, including improved treatment efficiency, reduced loading rates, and redundancy. While a single MBBR tank can remove organic matter from wastewater, it is not sufficient to achieve the desired level of treatment efficiency. A single MBBR tank has several limitations, including high loading rates, limited capacity, and a risk of failure.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.